Featured Stories

-

-

Elevating Pouch Manufacturing with Pearl Technologies' Cutting-Edge Solutions

For manufacturers seeking efficiency, precision, and safety in pouch production, Pearl delivers unmatched innovation across three standout... -

Faster Product Composition Analysis Equals Better Quality Assurance

Near Instant Testing and Reduced Costs to be Found

News | New Products

-

Nobelus Launches Films for Digital Embellishments

Label and Flex Pack Film Supplier Releases Coated Finished for Value-Add Embellishments

-

PACKZ 11 Launches with Industry-First RIP Integration

Plus extended CF2 format and automated support for 2-D Barcodes as Required by the Sunrise 2027 Initiative

-

Double E Group Acquires CAC, Further Enhancing its Strength in the Global Converting Industry

Double E Group, a global leader in converting components and web handling technology, has announced its acquisition of Converter Accessory Corporation (CAC)

-

Nobelus Launches Entry-Level Komfi® Thermal Laminator

FINISHING SOLUTIONS SUPPLIER OFFERS NEW JUNIOR 52 LAMINATING SYSTEM

-

Double E Group Mourns the Loss of Founder and Converting Industry Pioneer, Richard Edward Flagg

Double E Group announces with profound sadness the passing of its founder, Richard Edward “Ed” Flagg, on June 23, 2025. He was 85.

-

Convertech Brand to Fully Transition to Double E Group Same Team, Same Excellence, Unified Name

Double E Group has announced that Convertech, one of its subsidiaries and a trusted provider of core chucks and shaft solutions for the converting industry, will now operate solely under the Double E Group brand.

-

Pulse is Making Print Simple at Labelexpo Europe 2025

Narrow web ink specialist Pulse is Making Print Simple at Labelexpo Europe 2025, as it challenges flexo printers to rethink how they work and shows solutions that turn production bottlenecks into revenue generators.

Expert Advice

Static Beat | 'GeeZE' Rules for Static Readings

- Published: May 24, 2017, By Kelly Robinson

Follow the three ‘GeeZE’ rules for taking repeatable, reliable static readings.

Static sparks are bad. Sparks can shock operators and damage thin coatings such as release layers. Sparks that are too small to see, hear, or feel can ignite flammable solvent vapors. And, sparks deposit spots of static charge on webs that can cause sticking and jamming of cut sheets. Often, our main goal for static control is to suppress sparks.

Static sparks are bad. Sparks can shock operators and damage thin coatings such as release layers. Sparks that are too small to see, hear, or feel can ignite flammable solvent vapors. And, sparks deposit spots of static charge on webs that can cause sticking and jamming of cut sheets. Often, our main goal for static control is to suppress sparks.

Static sparks occur when static levels are too high. Keep static low to suppress sparks. While this sounds simple, static is not simple. How much is too much? What level is low enough? To know, we must measure static using a static meter.

A handheld static meter is an electrostatic fieldmeter. Even a device that displays static in ‘KV’ or ‘kilovolts’ responds to the electric field at the meter’s sensor. To take repeatable, reliable static readings, follow these three simple “GeeZE” rules. GeeZE rhymes with cheese.

- G - Ground the static meter.

- Z - Zero the static meter.

- E - Empty the "measurement sphere."

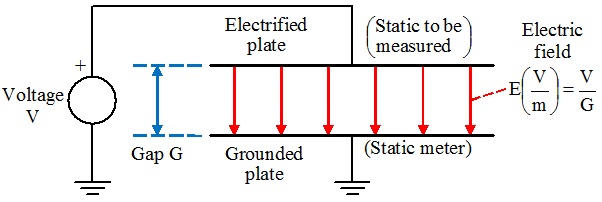

To understand these rules, let’s first look at how a fieldmeter works. In the simple, “parallel plate” model for our static meter in Figure 1, the voltage V on the upper plate represents the static that we want to measure. Our static meter is the grounded, lower plate located distance G below the upper plate. The electric field E “connects” the static that we want to measure with the meter. Our meter reads the electric field, which, when the plates are much bigger than gap G, is the voltage V divided by the gap G. The electric field E has units of volts per distance.

Even though the display on most static meters says “KV,” the units of the electric field are “KV per distance.” Most handheld fieldmeters are calibrated for a one inch gap, so the electric field is displayed in kilovolts per in. (KV/in). Some meters are calibrated for other gaps, so read the instructions. For example, the Meech 983v2 Static Locator is calibrated for a 150 mm gap. The common, industry standard for acceptably low static, 5 KV/in., would read 30 KV on this meter. The units for the electric field on the Meech meter are really KV per 150 mm, and 150 mm is about 6 in.

In my experience, sparks occur when the electric field is bigger than 15 KV/in. So, when the field exceeds 15 KV/in., improve static control with the goal of keeping static below 5 KV/in. Now that we’ve looked at how a fieldmeter works, the three GeeZE rules are sensible.

RULE 1

Ground the static meter. If the lower plate in Figure 1 is ungrounded, its voltage is probably not zero. In fact, the voltage of the meter can be pretty much anything up to about 30 KV, depending on how much charge is on the person holding the meter. Static readings can be highly variable because the static on the web is variable. To take repeatable readings, we must eliminate all other sources of variability. Static readings are highly variable anyway. We must not add more variability.

I wear static dissipative shoes when I take static measurements so that I am grounded, at least when the floor is conductive or static dissipative. Even so, I have a habit of touching the grounded machine frame with one hand while I take the static reading with my other hand. I recommend that you also develop this habit. Touch the machine frame when you take a static reading. The human body is mostly salt water, which is conducting. So, touching the machine frame grounds your body.

RULE 2

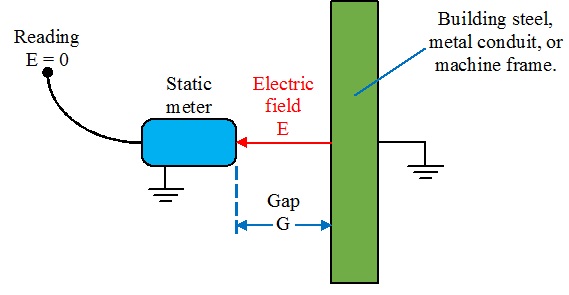

Zero the static meter. The reading on a fieldmeter drifts with time and temperature. Nearly every sensitive electronic instrument drifts with time and temperature. So, your fieldmeter is designed to be zeroed so that the readings are repeatable. The best way to zero the static meter in Figure 2 is to measure the static on a grounded metal object like building steel, a metal conduit, or the machine frame.

Of course, the static on grounded metal is zero. So, we know that the meter should read zero. Hold the meter at the proper gap G and press the “zero button” or adjust the display to read zero.

Now, we’re ready to take a static reading.

RULE 3

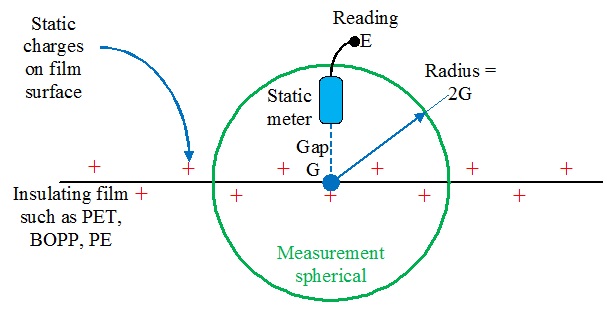

Empty the measurement sphere. Well, what is a “measurement sphere?” Fieldmeters display the electric field at the meter’s sensor. While the field E in our parallel plate model in Figure 1 is simple, most of the time, the shape and the size of the electric field is more complex. The field has a different shape and size for each different measurement geometry. Any nearby conducting object will reduce the static reading. Take a static reading at a location where all other conducting objects are far away so that the meter responds only the static on the web. Your static meter is calibrated to read accurately when the meter responds only to the charge on the web.

To ensure that the meter responds only to the static on the web, imagine that you can draw a dot in Figure 3 on the web just below the fieldmeter. The dot is distance G from the meter. Your dot becomes the center of a sphere that, in your mind’s eye, expands out to a radius of 2G. This is the “measurement sphere.” For reliable readings, the measurement sphere in Figure 3 must be empty, well, except for the meter and your hand. For a meter calibrated for a gap G of 1 in., the measurement sphere has a diameter of 4 in., which is just a little bit bigger than a large softball. So, to take a reliable static reading, you’ll need to find an open space on the machine about the size of a softball.

If you use a meter calibrated for a 150-mm gap, the measurement sphere has a diameter of 600 mm, which is about the size of a large, 2-ft diameter beach ball. Any conducting object inside the beach ball reduces the reading. For this reason, I prefer using a meter calibrated for a smaller gap. I use a Monroe 257D Electrostatic Fieldmeter calibrated for a 1-cm gap. For my meter, the measurement sphere has a diameter of about 1.5 in., which is about the size of a ping pong ball.

Static readings are important for diagnosing static problems and for verifying static control. Follow the three GeeZE rules to make repeatable, reliable static readings:

- Ground the meter.

- Zero the meter.

- Empty the measurement sphere.

I invite you to ask questions about this column and to suggest future topics. My email address is: This email address is being protected from spambots. You need JavaScript enabled to view it..

Static control expert Dr. Kelly Robinson, president of Electrostatic Answers, has 27+ years of experience in problem-solving and consulting. Kelly writes PFFC's Static Beat column and the Kelly on Static blog. Contact him at 585-425-8158; This email address is being protected from spambots. You need JavaScript enabled to view it.; www.electrostaticanswers.com.