Featured Stories

-

Elevating Pouch Manufacturing with Pearl Technologies' Cutting-Edge Solutions

For manufacturers seeking efficiency, precision, and safety in pouch production, Pearl delivers unmatched innovation across three standout... -

Faster Product Composition Analysis Equals Better Quality Assurance

Near Instant Testing and Reduced Costs to be Found -

Methods to Precisely Measure Tension and Web Control

How to Control Automatically Within Set Parameters

News | New Products

-

PACKZ 11 Launches with Industry-First RIP Integration

Plus extended CF2 format and automated support for 2-D Barcodes as Required by the Sunrise 2027 Initiative

-

Double E Group Acquires CAC, Further Enhancing its Strength in the Global Converting Industry

Double E Group, a global leader in converting components and web handling technology, has announced its acquisition of Converter Accessory Corporation (CAC)

-

Nobelus Launches Entry-Level Komfi® Thermal Laminator

FINISHING SOLUTIONS SUPPLIER OFFERS NEW JUNIOR 52 LAMINATING SYSTEM

-

Double E Group Mourns the Loss of Founder and Converting Industry Pioneer, Richard Edward Flagg

Double E Group announces with profound sadness the passing of its founder, Richard Edward “Ed” Flagg, on June 23, 2025. He was 85.

-

Convertech Brand to Fully Transition to Double E Group Same Team, Same Excellence, Unified Name

Double E Group has announced that Convertech, one of its subsidiaries and a trusted provider of core chucks and shaft solutions for the converting industry, will now operate solely under the Double E Group brand.

-

Pulse is Making Print Simple at Labelexpo Europe 2025

Narrow web ink specialist Pulse is Making Print Simple at Labelexpo Europe 2025, as it challenges flexo printers to rethink how they work and shows solutions that turn production bottlenecks into revenue generators.

-

ROTOCON to debut at Labelexpo Europe with three machine demonstrations

ROTOCON will make its Labelexpo Europe debut, exhibiting together with HS Machinery on stand 4D21.

Expert Advice

Release Liners: A Worldwide Special Report: Release LinersPackaging Waste?

- Published: November 01, 2002, By AWA Alexander Watson Assoc.

Part 1 | Part 2 | Part 3 | Part 4 | Part 5

An opinion shift that release liners are packaging rather than process waste will have consequences across the supply chain.

There can be no question release liners constitute an essential part of the production and application process for self-adhesive labels—but afterward they are thrown away. Whether release liners are classified as “packaging’” waste or simply as “process” waste, there is undoubtedly an ethical issue in relation to their disposal. They are high-value items and often highly engineered, and today—when globally we are concerned with making the most of the world’s dwindling resources—it may well be considered unacceptable that they simply go into landfill.

European Legislation

Europe is ahead of other global regions in addressing this issue and has taken the route of legislation. In 1994 the European Union (EU) issued its first Packaging and Packaging Waste Directive, aimed first at reducing the amount of landfill and incineration without energy recovery (two major global environmental concerns) and second at driving down the levels of waste in the packaging industry as a whole. The directive encourages minimization of the amount of material used in packaging applications, re-use of components, recovery, and recycling. That “encouragement” has consisted of a series of targets for recovery and recycling, coupled with financial penalties for non-compliance.

U.K. Milestone Ruling on Release Liners

Until this year, release liners were classified as process waste, but current thinking is moving toward the idea they are, indeed, packaging waste. The British government already has taken this route, which could have serious implications for the U.K.’s roll-label industry, as it attempts to compete with European neighbors while shouldering the financial burden of responsible liner waste disposal. The U.K.’s decision undoubtedly will affect thinking across Europe and the world as a whole. France is indicating it is likely to take the same stance as the U.K.

This shift will have consequences across the supply chain in relation to release liners. The release liner manufacturer and laminate manufacturer necessarily create waste during production. The label printer creates waste during conversion—offcuts and trim. The packaging manager is left, after label application, with release liner for disposal. All may be held responsible for the liner waste at their premises.

New Recovery/Recycling Targets in Pipeline

A revised set of EU recovery and recycling targets is due later this year. They will be much more severe than the originals, yet many countries in Europe still fail to comply with the original requirements. While the EU targets apply across all member countries, implementation is the responsibility of the individual countries.

Waste Management Infrastructures

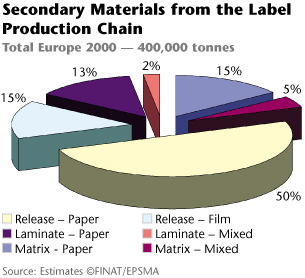

FINAT, the international self-adhesive labeling association based in the Netherlands, along with the European Pressure Sensitive Manufacturers Association, is spearheading an initiative to “wake up” the individual EU countries to the need to develop waste management infrastructures—matrix, release liner, and unused laminate. FINAT is active in helping the industry in Europe find companies able to collect, recycle, and recover label by-products and in providing technical assistance in setting up such schemes.

A few EU countries, particularly Germany, have strong, established waste management networks across the whole packaging industry, including the self-adhesive label industry in relation to release liners. However, most countries have taken few or no steps toward implementation. Many countries do not even have fully-established waste management infrastructures to enable recycling and recovery, let alone documentation of levels achieved.

Proposed EU Targets

Discussions affecting the packaging industry as a whole go on in the European Parliament, and there is no consensus on what the revised targets should be. Current proposals involve 55%–80% recovery of all materials—including release liner where it is classified as packaging waste—and different recycling targets for glass (60%), paper (60%), metals (50%), and plastics (22.5%). Agreement on a final legally binding document is not expected before year end.

Environmental Responsibilities

Environmentalists argue there is no good reason why the self-adhesive label industry should delay in positioning itself to meet the challenge of the EU legislation. The fact remains there is no need for release liner disposal in landfill sites or by incineration without energy recovery. Legislation like the EU Packaging and Packaging Waste Directive, with its attendant financial penalties, has driven change in Europe’s packaging industry, but it also could be considered the moral responsibility of the industry, both in Europe and across the globe, to face the issue fairly and squarely on its own.

Some schools of thought say the benefits would be twofold. First, it would be environmentally responsible to put in place a Europe-wide waste management infrastructure that would optimize the reuse and recycling of release liners. Second, such an industry-specific initiative could create a “level playing field” in the European self-adhesive business arena and help maintain a platform for profitability in an industry where margins are heavily under pressure.

The Bottom Line

The bottom line is profitability for the whole supply chain—and it is worth remembering that waste management firms like US-based Channeled Resources and its MaraTech subsidiary, as well as Ahlstrom Werk in Germany, have proved it is possible to recover, reuse, and recycle film and paper release liner—and to make a profit while doing so.

Visit AWA at awa-bv.com.

Part 1 | Part 2 | Part 3 | Part 4 | Part 5