Coating | Solution Delivery for High-Precision Coating, Pt. 2

- Published: March 22, 2016, By Todd Arndorfer, Carestream Contract Manufacturing

Establish a proven, effective protocol to maintain your solution delivery system, then train operators, mechanics, and engineers to follow it to the letter.

Proper management of solution delivery systems and procedures ensures optimum product quality and cost control. Throughout the process, clear, operationally sound procedures help maintain technical efficiency. Part One of this article focused on system design. Now we’re ready to discuss how system performance can be optimized to improve product quality and yield.

Proper management of solution delivery systems and procedures ensures optimum product quality and cost control. Throughout the process, clear, operationally sound procedures help maintain technical efficiency. Part One of this article focused on system design. Now we’re ready to discuss how system performance can be optimized to improve product quality and yield.

Purging the System

Before beginning a new coating run, all residual cleaning solutions, air, and off-concentration product solutions must be purged from the system.

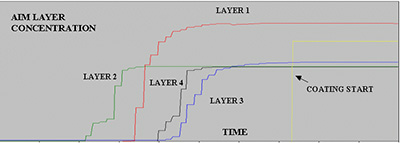

Typically a solution delivery system is best designed so the fluid flows uphill, since air will rise above liquid, making it easier to purge the bubbles out of the system. A best practice is to begin by removing air from the line with water or another low-viscosity solvent, and then purging with the typically higher-viscosity (and higher cost) product solution. In most cases, purging at higher than aim flow will cleanse the system more quickly and actually result in less fluid loss prior to coating than a lower purge rate.

Conductivity or density can be used to measure the purity and progress of the purge in real time and to minimize waste and purging time for efficiency’s sake.

Another way to reduce waste is to minimize system volume by shortening piping or hose lengths as much as possible.

Solution Delivery: Control Flow

Once the system has been purged of contaminants, you’re ready to optimize delivery of your coating solution through the die and onto the substrate. A flow meter with a feedback control loop to the pump is recommended for pre-metered coating. This setup will provide more stable flow by automatically compensating for changes in tank liquid level, solution viscosity, and filter backpressure. Such a system can potentially avoid the need for post-coating thickness verification. When choosing a flow meter, consider how easily it can be cleaned in combination with the contamination potential of the coating solution. The image below shows an inline filtration and flow control system.

Consider soft-walled delivery lines to absorb pressure pulsations. In some cases, pulse-dampening flow components may be necessary for critical applications where thickness variation must be minimized. Flow pulsations can cause quality issues with the coated product; monitoring their frequency can help identify root causes so they can be reduced.

Inline Solution Mixing

Inline mixing of cross-linkers or active ingredients that are prone to degradation is a good way to avoid kettle life concerns and negative impacts on product quality over time. The purging sequence of inline mixed components requires special consideration. When a coating process inline mixes an ingredient, it is good practice to purge the bulk solution first, and then bring in the inline mix, minimizing waste of higher-value material.

The choice between using static or dynamic mixing methods is an important consideration for quality assurance, because insufficient inline mixing can cause streaks in the coating or functional failure of the product itself.

Static mixers are structures positioned inside the pipe or tubing to redirect the fluid so it diverges and crosses; velocity and angles of flow cause the fluid to mix. If streaks are visible in fixed locations with a static mixer, a second or third mixer may need to be added to improve the blend. If static mixing is still not sufficient, for example in cases with a big differential in viscosity between the inline ingredient and bulk solution, dynamic mixing may be required.

A dynamic mixer is a powered device that churns the solutions together inline with the fluid flow. Insufficient dynamic mixing can cause streaks that shift in crossweb position. In that case, the mixer’s power or speed may need to be increased. It’s a good idea to review the data provided by the mixer manufacturer as guidelines; usually you will have to experiment to see what works for each mixture.

Consider also the product solution type. In dynamic mixing, be aware that for a shear-sensitive solution like an aqueous dispersion, you might need to limit the mixing power and speed so you don't degrade or coagulate the solution leading to poor coating quality.

Control Temperature

Part 1 of this article covered the importance of controlling the coating solution temperature to regulate solution viscosity and ensure smooth delivery. If the coating die and solution are not at the same temperature, down-web thickness can change as the die heats or cools. Non-isothermal operation of curtain, slide, or slot coating applicators can lead to cross-web anomalies and defects.

The simplest way to control temperature is to measure it inside the kettle or tank from which it is being pumped, and then compare it to the temperature of the coating die. If there's a significant difference, measure the temperature of the solution coming out of the coating die, compare that to the tank temperature, and see how long it takes to stabilize. For example, if the kettle solution is 60 deg and the die is 70 deg, the solution might stabilize somewhere in between. Look at the rate of temperature change and coating uniformity, and evaluate any impact. If the coating temperature is not stabilizing at an acceptable level and you’re seeing related defects, you may need to adjust the supply tank temperature.

Another option is to install a temperature control system on the piping and/or on the coating die. Some coating dies are built with a jacket through which warm water flows around the die to keep it at a desired temperature matched with the coating solution. Carestream uses jacketing for both the die and the solution delivery pipes, primarily because many of our imaging products are gelatin-based. Gelatin stays soluble above 100 deg F, so that's the temperature typically used to jacket the system. For your products, consider the minimum temperature needed to keep key ingredients soluble or conversely what maximum temperature to stay below to avoid degradation of sensitive ingredients.

The first option is easier and less expensive, as you just simply try to match the tank and die temperatures. If higher temps are required you will likely need the jacket, especially at the coating die to avoid metal thermal expansion that can impact crossweb uniformity.

Clean the System

A new, optimized solution delivery system will work well for the first few coating runs, but if it’s not kept clean, system performance will degrade over time. Note the buildup on the interior of the poorly cleaned pipe pictured below.

We’ve mentioned this before, but it bears repeating: Insufficient system cleaning can lead to big problems, including the following:

- Repellencies

- Lines/Streaks

- Functional product failure (i.e., inadequate curing, alignment, desensitization, etc.)

- Poor delivery system reliability (operational)

- Decreased filtration performance (higher costs)

To avoid these predicaments, study what solvents and aids work best for cleaning the coating solution out of the system. Flush the entire system as soon as possible and before purging with air, to avoid curing and drying any residual material (which makes cleaning even more difficult).

Dried material inside the lines can flake off in the next coating run and cause streaks or spot defects, or prevent the coating from adhering properly. Other contaminants can cause repellencies, which are small craters in the coating.

Functional product failure happens less frequently, but for a highly technical product with sensitive active ingredients, contaminants might interfere with the properties of the coating.

Decreased filtration performance also happens when a solution dries up inside the lines and flakes off in the next coating run. Excessive residue plugs the filters more quickly. Since filters are a significant cost, it’s beneficial to get the contaminants out of the system beforehand.

The reliability of a solution delivery system’s functional components also can be degraded by insufficient cleaning. For example, internal parts of the pump can suffer excessive wear, causing it to fail sooner. In extreme cases, the residue can cause significant damage and even break parts inside the pump. Poor cleaning also affects the accuracy of flow meters. Some of these rely on the turning of small paddles or gears inside; if those are not clean, they won't turn as freely and flow measurement will be off. Buildup in tubing also can affect the accuracy of more sophisticated flow meters that measure flow rate indirectly via the Coriolis Effect.

Verify and Validate

Verifying the effectiveness of the cleaning process is essential, and best achieved with upfront testing. Measuring cleanliness is difficult because the system consists of mostly internal surfaces, such as the inside of a pipe, tube, or coating die. Therefore, devising a repeatable procedure with validated results to meet requirements will dramatically improve efficiency, reduce costs, and maintain high product quality.

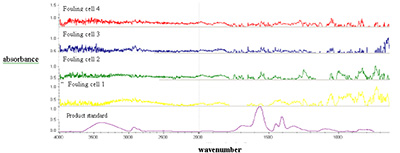

Measure the purity of the flush system water or solvent to find out how well it’s working. Purity can be assessed visually or optically by checking clarity, by measuring conductivity, or by subjecting samples to offline lab testing to check for trace contaminants through FTIR (Fourier Transform Infrared Spectroscopy) or other methods.

The last way to verify cleanliness is to physically look inside the system by taking things apart after cleaning. For example the pump mechanism can be opened up for visual examination. For pieces that can’t be dismantled, a fouling cell can be installed—a little window in the piping flow, like a porthole through which we can check the interior surface cleanliness over time. Fouling cells are often placed in two or three key locations throughout the system between the tank, pump, flow meter, and coating die. Not all contaminants are visibly obvious. Offline fouling cell analysis in the lab with optical or chemical residual testing can be performed to quantify cleaning effectiveness.

Once the cleaning sequence is defined and its efficacy is validated, try to create a standard clean/flush process that can be reliably repeated without needing to do these verifications every time.

Clean and Lean

Optimized cleaning processes will minimize product changeover time and avoid waiting, in keeping with Lean Principles. How clean does the system really need to be? This will depend upon the operating requirements of your equipment, the solutions you’re running through it, the coated substrate or product, and quality/performance specifications. With all these results in mind, analyze your process and eliminate, simplify, and automate—in that order. Get rid of the steps that don’t contribute materially to results. Simplify where possible; standardize procedures for repeatability without constant reverification and testing. Operators should be trained to implement a well-documented procedure. If possible, automate the sequence to reduce operator-induced variability.

Testing to verify cleanliness after every coating run is impractical and inefficient, but keep an eye on trends in key product quality parameters from one run to the next to monitor system performance. You also can monitor the amount of solution waste per run to see if anything in the system has changed. If negative factors such as spot defects or streaks are trending in the wrong direction, take a look at how the established solution delivery and cleaning practices are being followed. Have operators strayed from the specified procedures? If not, there may be a problem with the system that you need to go back and fix.

Conclusion

Solution delivery systems play a major role in the quality of precision coating. Excellence in system design and maintenance minimizes coating defects and costs, expands the longevity of equipment, and optimizes product performance. Establishing a proven, effective protocol for every process—then training operators, mechanics, and engineers to follow it to the letter and monitoring results—will go a long way towards maintaining high quality and customer satisfaction.

ABOUT THE AUTHOR

As technical account manager at Carestream Contract Manufacturing, Todd Arndorfer identifies, attracts, and commercializes new manufacturing business for Carestream's polyester film and precision coating assets. Throughout his previous six-year tenure managing manufacturing operations at Carestream Health Colorado, Arndorfer increased profit and led step change improvements in safety, quality, and delivery. Over the course of his 26-year career, Arndorfer has held product development and process engineering roles at several other locations, including Ferrania, Italy, and Rochester, NY. Arndorfer earned his B.S. in chemical engineering at the University of Wisconsin-Madison. Contact him at todd.arndorfer@carestream.com

To read Part 1 of this article, click here.