Unwind and Rewind Web Guides

- Published: July 31, 2023

By Aravind Seshadri, President, Roll-2-Roll Technologies LLC

Unwind and rewind web guides play a crucial role in the roll-to-roll processing industry, ensuring proper alignment of the web at the entry and exit points of the machine. The performance of these systems relies on several factors, including sensor location and installation actuator selection, motor type, etc. The second part of this article will cover the mechanical design considerations, while this installment covers the sensor location and installation.

Introduction

Terminal web guides are devices employed at the entry and exit points of a roll-to-roll machine to align the web to the desired cross-machine location accurately. The entire roll of the web, situated on the unwind/rewind stand, is moved along the cross-machine direction for proper alignment. These terminal guides are known by various names, such as shifting stand, shifting base, shifting sidelay, uncoil and recoil, payoff and tension reel, and roll positioning stands.

Although unwind and rewind web guides may seem similar, their installation and control system designs exhibit crucial differences. A well-designed terminal guide must have an appropriate mechanical design and control system based on process parameters.

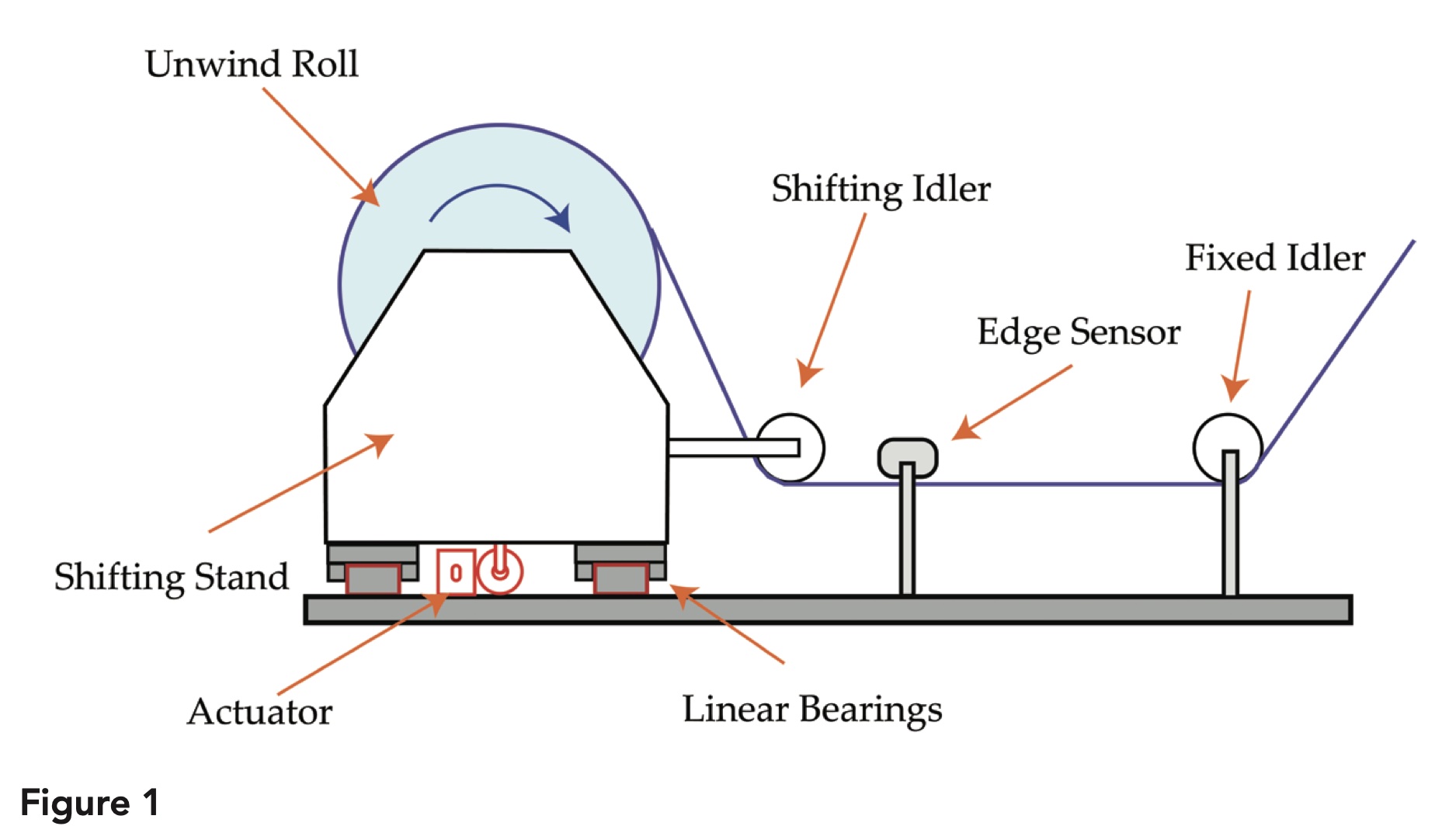

Unwind Guiding

Unwind guiding involves moving the entire unwind roll assembly in the cross-machine direction. The stand is typically mounted on low friction linear bearings and moved using an actuator. A web edge sensor, installed on the fixed machine frame, is usually placed just downstream of the last idler that shifts with the unwind stand. The sensor’s feedback is used to move the unwind stand, ensuring the web’s correct cross-machine location within the roll-to-roll machine. Below are key items to check for proper installation of unwind guides for edge guiding application:

- Ensure that the web edge sensor is fixed and does not move with the unwind shifting stand;

- Position the web edge sensor just downstream of the last shifting idler on the unwind stand;

- Install the sensor as close as possible to the last shifting idler; and

- Add at least one shifting idler on the unwind stand to prevent diameter variation from causing plane changes at the sensor.

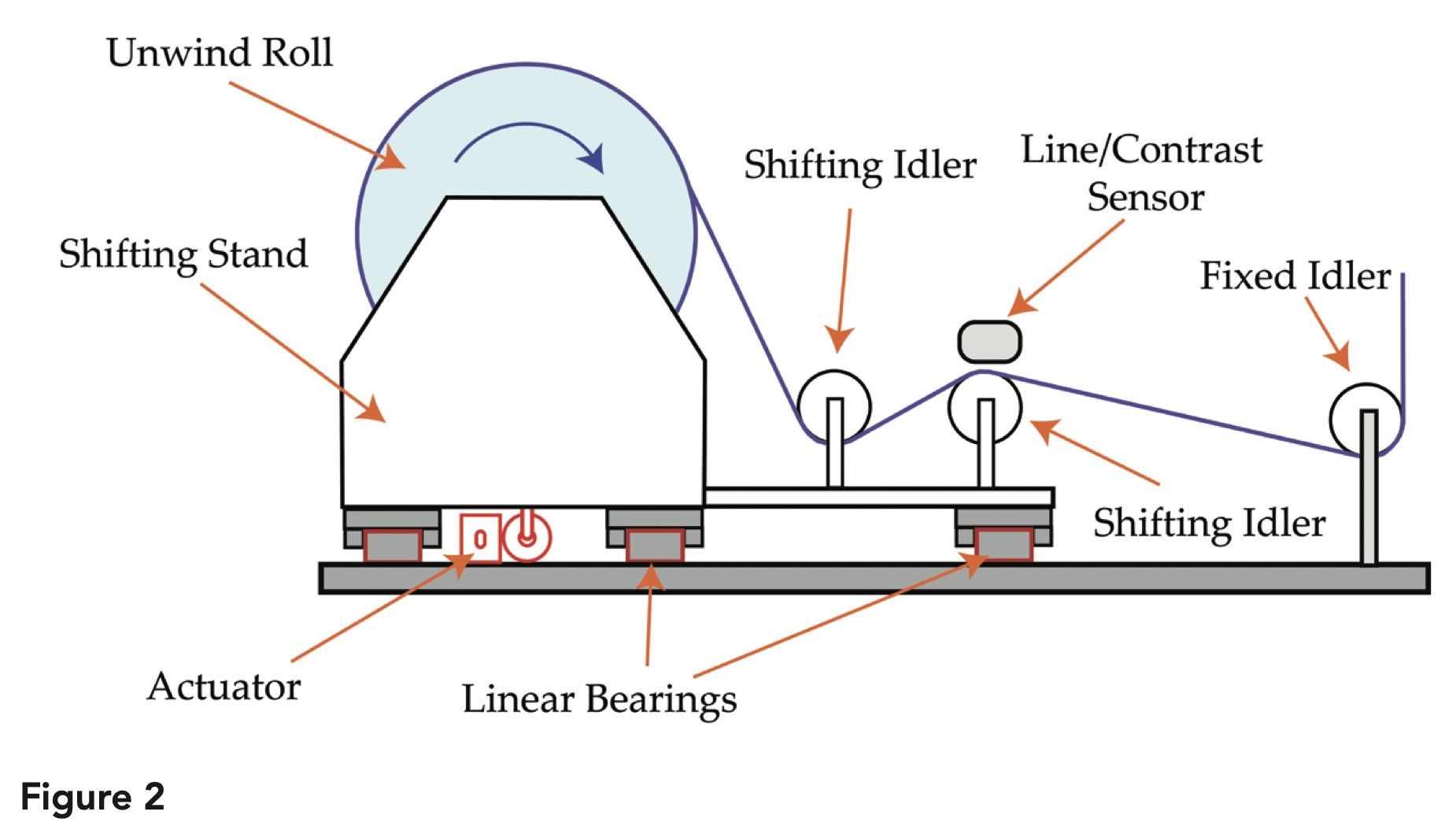

The sensor installation when a line/contrast sensor is used is slightly modified as shown here with an additional stabilizing roller that moves with the unwind stand. Below are key items to check for proper installation of unwind guides for line/contrast guiding application:

- Ensure that the line is fixed and does not move with the unwind shifting stand;

- Position the line/contrast sensor just downstream of the last shifting idler on the unwind stand;

- Add at least one shifting idler on the unwind stand to prevent diameter variation from causing plane changes at the sensor; and

- Install the line/contrast sensor to look at the web supported by a backup roller. Ensure that the backup roller also moves with the unwind stand. And ensure that the backup roller is the last roller on the unwind stand.

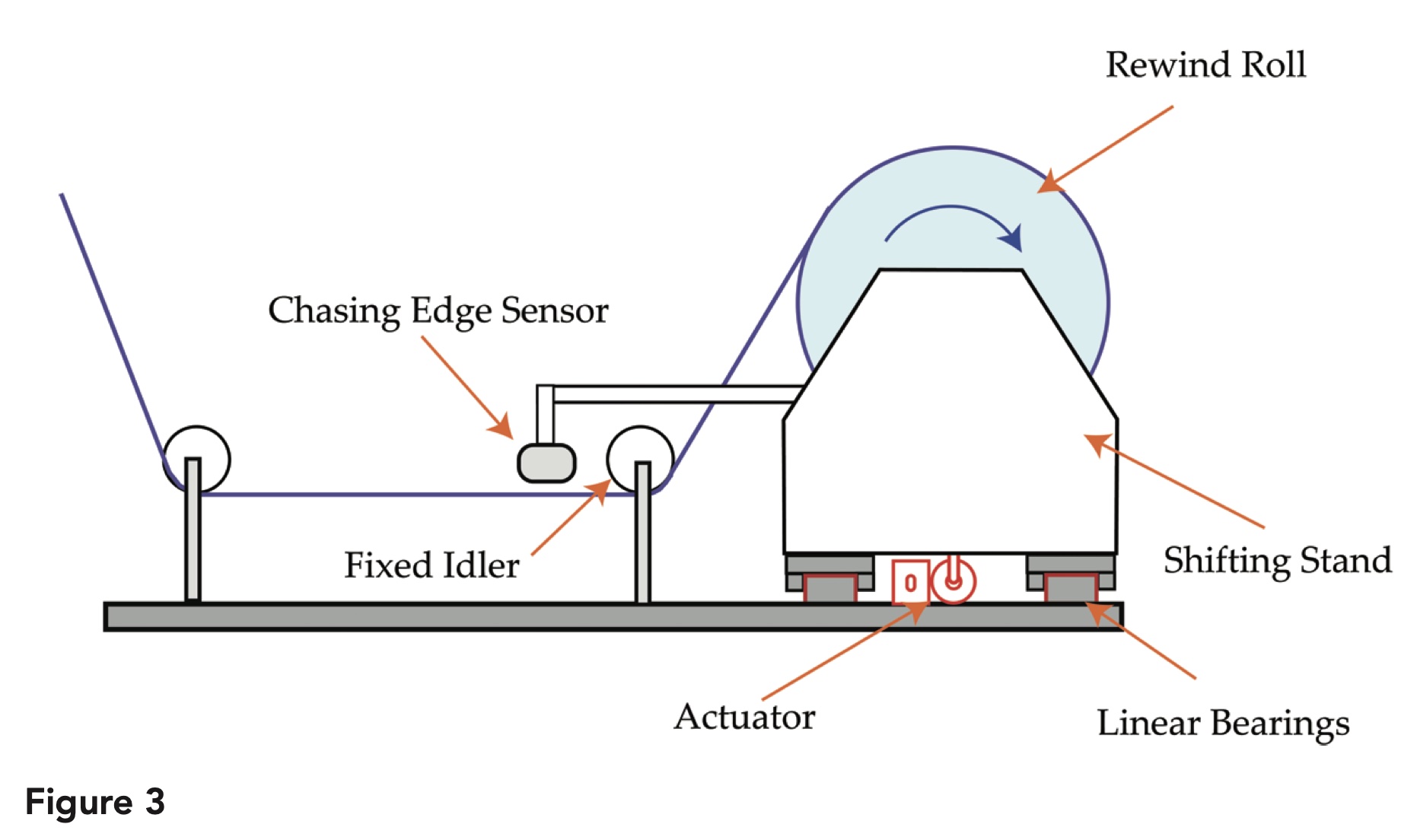

Rewind Guiding

Rewind guiding involves the winding roll chasing the web, which technically does not guide the web. The sensor is mounted to the rewind stand, moving when the stand translates. The control system aims to maintain a constant relative position between the incoming web and the rewind stand, resulting in a straight wound roll. Installing the sensor on the translating rewind stand provides a measurement of the incoming web relative to the stand.

However, if the sensor is installed on the fixed machine frame, the relative position between the web and the stand would be lost, preventing feedback loop closure. For rewind applications, the sensor should always be installed on the moving rewind stand. The checklist for proper rewind guiding installation includes:

- Ensure that the web position sensor is mounted on the moving rewind carriage;

- Verify that the sensor mounting fixture is stiff;

- Install the sensor to observe the web just upstream of the last fixed idler before the rewind stand; and

- Position the sensor as close as possible to the last fixed idler upstream of the rewind stand.

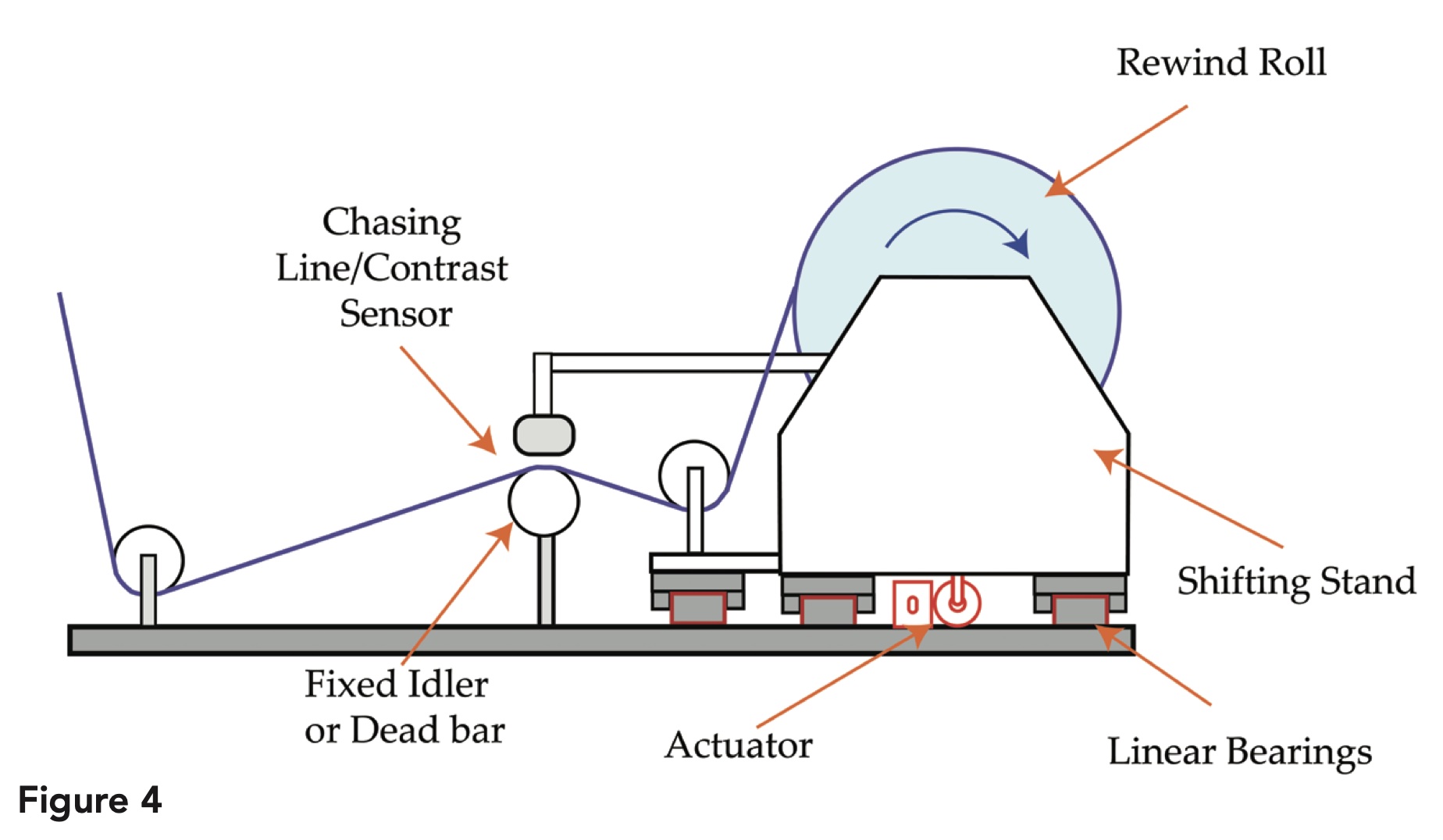

Similar to the unwind case the sensor installation when a line/contrast sensor is used is slightly modified as shown here with an additional stabilizing roller. In this case this stabilizing roller does not move with the rewind stand and it is a fixed idler roller. In some cases a dead bar may also be used.

Below are key items to check for proper installation of rewind guides for line/contrast guiding application:

- Ensure that the line/contrast sensor is mounted on the moving rewind carriage;

- Verify that the sensor mounting fixture is stiff; and

- Install the sensor to observe the line/contrast position on the last fixed idler before the rewind stand.

Conclusion

Terminal web guiding systems play a crucial role in ensuring the accurate and efficient processing of web materials in various industries. Apart from the sensor location several other key components such as actuators, motors, sensors, control systems and mounting configurations have a significant impact on the performance and reliability of these systems. In a later article, the mechanical design considerations for these types of web guides will be discussed in detail.

About the Author

Aravind Seshadri has more than 18 years experience in the design of control systems for roll-to-roll systems specifically in lateral web dynamics, tension control, print registration and sensor development with over 25 publications and two patents. His contributions have been recognized by AIMCAL (John Matteucci Awards for Technical Excellence in 2017) and ASME (Rudolf Kalman Best Paper Award in 2011). He is President of Roll-2-Roll Technologies, a leading supplier of web guiding solutions for the roll-to-roll processing industry. He can be reached at aravind@r2r.tech or through https://r2r.tech.