Materials Lead The Way

- Published: November 27, 2023

By Susan Stansbury, Industry Consultant

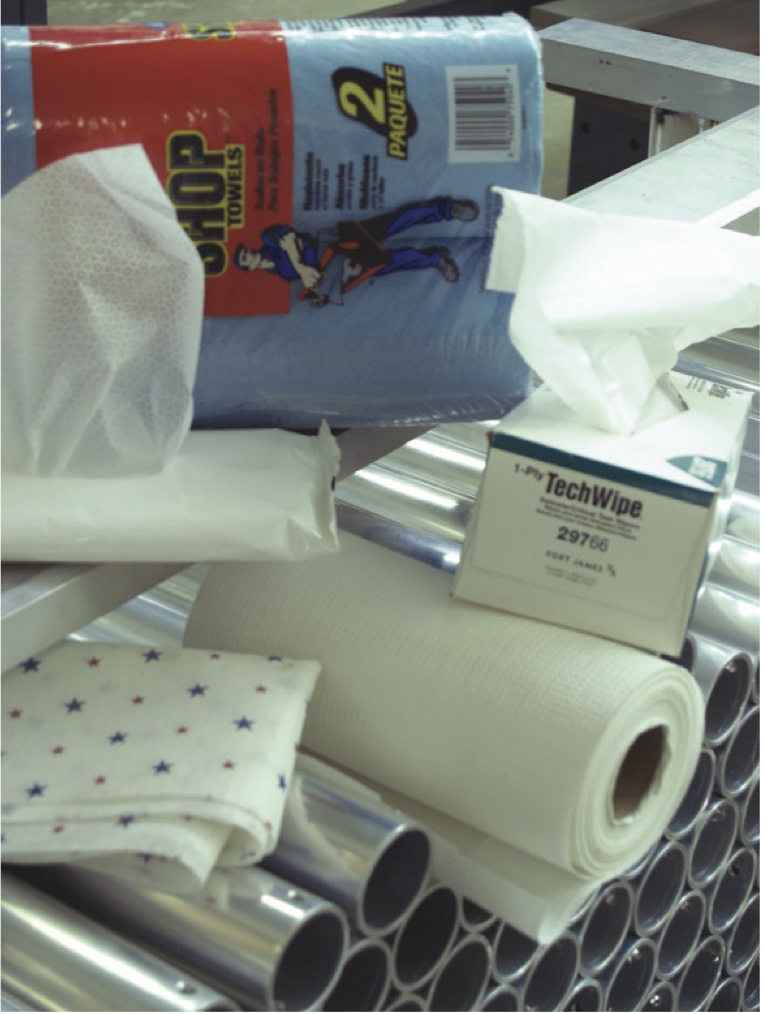

Increasingly, materials are going beyond their functionality of just a few years ago. Several factors account for looking at substrates as super performers. Careful selection is both critical to good outcomes and can also be a detriment to product design. It pays to know how to figure out selection of these base layers.

Increasingly, materials are going beyond their functionality of just a few years ago. Several factors account for looking at substrates as super performers. Careful selection is both critical to good outcomes and can also be a detriment to product design. It pays to know how to figure out selection of these base layers.

To understand the myriad possibilities in materials choices, these are some of the factors to consider:

- Materials building blocks begin with pulp, fibers, resins and all the raw strands that come together to form a web.

- Web forming processes determine how the items above make a continuous mat that has certain strength (tensile, tear, machine direction, cross direction), smoothness or rough results, ability to combine with other materials and so forth.

- The range of web forming machines continues to evolve to meet the needs of substrate designers. Papermaking via fourdrinier or cylinder or combinations is still the mainstay.

Then nonwovens came into play.

- Then, add on nonwovens that spun out of papermaking such as airlaid which offers the prospect of combining fibers or layering the mat. When introduced before 1990, it was airlaid paper, and then the more modern-sounding term became airlaid nonwoven.

- Airlaid machines deliver materials ranging from very lofty and absorbent outcomes for bed pads and similar hygiene products, to thinner materials used in cutlery wraps, wet wipes, dry wipers and combine with other materials. Specialty “fluff pulp,” plus synthetic fibers and resins are common raw materials.

- Domtar’s Engineered Absorbent Materials (EAM) facility in Jessup, Georgia, recently celebrated the completion of a $90 million project adding a largescale airlaid production line. The EAM expansion makes Domtar a leading nonwovens provider.

- At Glatfelter, headquartered in Charlotte, NC, spunlace and airlaid “upgrade the performance of pads and increase the softness of the total product. The special blend of fibers is chosen for a faster multiple acquisition time and competitive rewet performance. The surface structure supports process-ability on converting lines.”

- Stronger nonwovens webs incorporate synthetics such as polyester and polypropylene made in other processes, from hydroentangling and spunlacing to needlepunch equipment. Again, results range from thin to very thick. Needlepunched substrates have been enjoying a renaissance from the older equipment to current “boutique” machines engineered to offer more final benefits, including high loft and scrubbing ability.

- In recent years, combining these materials has played a crucial role in making masks, with three-layer fabrics sandwiching an inner layer that filters Covid. At Biax-Fiberfilm polymer resins are transformed into fine microfibers and converted into a nonwoven web in one step via a conventional Meltblown system or their proprietary and patented Spun-blown® system technology.

Combinations offer an advanced role.

- From adhesives, liners and face stocks, changes roll out. “Direct Thermal Linerless blank labels manufactured in Ohio, offer excellent thermal sensitivity and consistent release. Our portfolio is available with semi-permanent and removable emulsion adhesives to allow you to meet a variety of application needs,” according to Avery Dennison.

- Promoters continue to tout their products that contain bamboo. I still question the distance to transport this material to U.S. converters and processing needed to treat the material for use.

Then there are plastics.

Then there are plastics.

- Different plastic films offer great strength, heat resistance or melting ability and many properties that make them great stand-alone options... or suitability to combine. When combined with airlaid, for example, one side can be absorbent and the other side moisture resistant such as for dental bibs.

The environmental dilemma.

- It’s no secret that sustainability has moved up the list when it comes to raw material sourcing, along with the standard requisites, quality, efficiency, cost and processability. While downstream activities are vital to bringing sustainability to life in tangible ways through products and partnerships, there is considerable value to be discussed in the actions being taken upstream to reduce our footprint, according to Nonwovens Industry.

- The problem is: Every day, the equivalent of 2,000 garbage trucks full of plastic are dumped into the world’s oceans, rivers and lakes. Plastic pollution is a global problem. Every year 19-23 million metric tonnes of plastic waste leaks into aquatic ecosystems, polluting lakes, rivers and seas. Further, “We will not recycle our way out of the plastic pollution crisis,” reported the UN Environmental Program.

- Source reduction, using less plastic, creating less waste, is always a first environmental effort.

- Some materials providers are trying to improve their environmental posture in other, indirect ways. “As the global personal care giant’s first wind farm project outside of North America, the 50 MW 12-turbine Cumberhead facility will supply the company with approximately 160,000 megawatt hours (MWh) of renewable energy every year. It’s an onshore wind farm that will supply around 80 percent of its U.K. electrical power. According to Nonwovens Industry, this will result in a total emissions reduction of 55,625 MTCO2e per year — the equivalent of taking 38,628 passenger vehicles off the road every year.

More About the Author

Susan Stansbury is a converting advocate with extensive experience in paper, converting, printing and related industries serving in roles including sales, marketing and product development. She is also the author of a new e-book, 14 Dinners and A Lunch: It’s Not About the Food, sharing stories about her decades in the industry.