CMYK=RGB - The Digital Color Revolution

- Published: January 31, 2004, By Matthew Bernasconi, Opaltone Graphic Solutions

Our printing industry is experiencing rapid changes. Yet the most obvious change that needs to be made has been overlooked for decades.

Waiting for a cab in Chicago during CMM, a young man approached me and asked, “Hey, bro, can I give you the best shoe shine in Chicago?” “No thanks,” I replied. But “no” simply was not part of this dude's vocabulary. After convincing me his secret potion would do the trick, he guaranteed if I wasn't completely satisfied, there would be no charge.

In the blink of an eye, he had my dull black suede shoes looking like a million dollars! “What do I owe you?” I asked. “For you, only four bucks.” As I reached for my wallet, he stopped me midstream with another proposition: “I'll bet you double or nothin' I can guess how many children your father had. But you've gotta be honest with me,” he urged. “If I get it right, you'll promise to pay me double.”

For the record I have three sisters and no brothers, so the answer, of course, is four. This seemed so obvious! But how could he know the answer? What clue was I missing? ... How many children did my father have? “OK, let's do it!” I said, as we shook hands on the deal. Again, he reminded me to give him my honest answer. His answer was, “None. Your mother had 'em all!”

The moral to this story: The obvious, even as it stares us in the face, is not so obvious!

Predictable and Consistent

At the end of the day, what are we trying to achieve when selling print? It's the same goal Coca-Cola, Starbucks, and McDonald's strive for: a predictable, consistent product.

The human brain has an excellent memory that thrives on monotony. If that Coke, coffee, and cheeseburger don't look, smell, and taste the same next time around, the consumer will lose confidence and won't make that critical return purchase (i.e., repeat business). Yet we expect print buyers to accept compromise and inferior print quality on a daily basis. How can a buyer have any confidence in the process if we can't get it right the second time around?

Don't you love this line? “That's because it's flexo; we can't do any better!”

The key to selling predictable and consistent print is to measure the ingredients. What's the first thing we (should) do when we bake a cake? Read the instructions on the back of the package. If we don't, we can be guaranteed it won't taste the same next time. How many times have you heard the saying: “If you can't measure it, you can't control it” or “You must print by the numbers”? Sounds good in theory, but how many actually implement a “process control program” in their facility?

What separates you from your competitor is simply how well you measure and control your process ingredients.

The Digital Revolution

Here we are in the 21st century, the so-called “digital revolution.” Vendors are preaching digital capture, digital workflows, digital proofing, digital plates, digital printing. Everything's digital! Then why, when it comes to matching that contract proof (or that dreaded reprint), can't we ever seem to get it right? The answer is simple: Because we commit the cardinal sin of constantly changing our printing ingredients. Just as the Chicago shoe-shiner cleverly disguised the obvious, let's take a step back and look at the most obvious (yet illogical) changes we make everyday in the flexo pressroom.

Ever wonder why we constantly swap out anilox rolls? Because that's how we get density, correct? All converters have an anilox inventory (anywhere from 200-lpi to 1,200-lpi rolls). Between $2,000 and $5,000/roll, they are a very expensive part of the flexo process. For example, a 20-roll inventory at $3,000/roll equals $60,000 (for one wide web press).

The theory is as follows: The higher the volume, the better the ink coverage. For example, if I want to print Pantone 286 blue (solvent ink), I would need to drop down to, say, a 360 lpi @ 5.0 bcm to hit the density from one coat of ink.

Stop right there! Why do we change anilox again? Oh that's right, to hit density from one coat of ink. Besides the printing industry, name one other industry in the world that puts down only one coat of paint?

What do we do when we paint a wall, lacquer a table, or spray paint a car? We never put down just one coat of paint. We usually start with a coat of primer, then the first coat followed by the second.

When was the last time you asked the salesman at your local paint store, “What volume paint rollers do you have for sale today?”

We have learned from experience that one thick coat of paint is not the answer. We need several thin coats to do the job right. Most importantly, from the same volume. Hold this thought for now; I will come back to it later.

Why Run Spot Colors?

The next ingredient we change constantly is the ink. Why do we run spot colors again? Seems an obvious question, but why do we? Let's explore our color reproduction choices more closely:

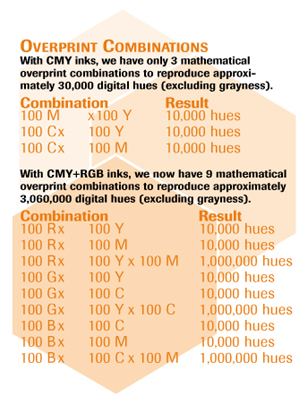

Choice 1: CMYK - Commonly referred to as process color, the CMYK system uses only four primary colors - cyan, magenta, yellow, and black - to reproduce an array of thousands of hues. This is achieved via a combination of halftone screening (dots) juxtaposed in such a way as to fool your eye and brain into believing you're seeing different colors or hues. This is called digital color reproduction.

The hue combinations are determined back upstream in prepress and approved via a CMYK contract proof. This is the most cost-effective reproduction process ever invented, because you never need to change your anilox or ink set. You simply change your plates. Wouldn't life be grand if all printing was done this way!

Of course, we know the CMYK system is limited in the amount of saturation (density) and hues it can deliver, which is of constant frustration to designers and print buyers. While CMYK is utopia from a print production standpoint, the wheels fall off when the buyers want colors that cannot be reproduced in CMYK.

Choice 2: CMYK + Spot Colors - When buyers can't get a particular color out of CMYK, what are the alternatives? We resort to CMYK and/or spot colors.

A spot color is a special color that is mixed with various colored pigments to deliver a particular hue the buyer typically cannot achieve from process CMYK. This is called “analog” color reproduction because the ink is mixed in the bucket and is always printed in a separate unit of the press.

The common belief is that we have better control throughout the production run because we don't have to worry about this ink overprinting with any other. It is always a single layer. The buyer runs a spot color to achieve consistency across a brand. The reality is, seldom is a spot color consistent from run to run. Why? A single ink layer will change in appearance relative to the density at which it's printed. This gets back to the “second coat” analogy I mentioned earlier. One ink layer always will vary in its coverage relative to what anilox volume applied it.

Another factor is the ink blend itself. Mixing ink sounds simple enough, yet we constantly see hue variations from batch to batch. Instead of printing with one thick ink layer, why not use two layers and build up density in the same way we paint a wall? That way we can use lower-volume anilox rolls and thinner ink films to keep our halftone screens from filling in completely (i.e., print contrast).

So what are the alternatives to spot colors? We know CMYK is already the answer for true digital color reproduction, yet we still are locked in the 19th century complementing CMYK's hue and saturation deficiencies with analog spot colors.

What if we went back to the drawing board and came up with another “digital” way of reproducing color in print that would reduce the need for spot colors (and varying anilox roll volumes) and at the same time expand the color range to satisfy demanding designers and print buyers. Sounds obvious enough, so why hasn't it been done already? It has.

Choice 3: Seven-Color Process; CMYK+RGB - The only thing constant is change, and as we accelerate through this decade you are going to witness the most exciting revolutionary change in print since the invention of CMYK more than 130 years ago. “The best way to predict the future is to invent it.” - Alan Kay.

Believe me, the term “seven-color process” is a huge paradigm shift in thinking. Rest assured, this technology has well and truly arrived and is here to stay.

The seven-color digital reproduction system uses standard CMYK plus additional RGB printing inks. The RGB inks have been developed specifically to complement the gamut deficiencies in CMYK. This color technology bridges the gap between digital CMYK and analog spot color reproduction. The CMYK+RGB reproduction system is totally digital.

The digital press of tomorrow (which is here today) doesn't change its ink. When was the last time you changed the ink cartridge in your printer to load that special color? This is true digital (not analog) color reproduction.

Imagine your flexo press with only seven process inks - C, M, Y, R, G, B, K - never having to change anilox rolls, just changing out the plates. Of course, it sounds too good to be true! So let's take a quick look at the reasons why you should consider implementing this cost-effective digital color solution.

Quit Burning Cash

Everyone wants it faster, better, cheaper (free, if you can get it), and with more variety. For the printer, this spells only one thing - faster make-ready times. Every time you wash up that print station and mix that analog ink in the bucket, you are burning up serious cash. Constantly purchasing and refurbishing anilox rolls to get the strongest ink coverage - another cash burner. Imagine having a process ink inventory of only seven colors and simply changing your plates.

As CMYK hues are reproduced digitally with colored halftone dots, the same applies to CMYK+RGB color reproduction. Totally digital. While we never will eliminate spot colors completely, this system is designed to slash spot color ink inventories drastically. Anilox roll inventories also will be reduced. Remember the only reason we carry various anilox rolls is to achieve varying densities.

With the implementation of CMYK+RGB printing, the best place to see high-volume anilox rolls in the future will be the print museums (alongside the exhibit on how we used to make copious analog spot colors). In fact, the flexo process itself already is under threat from emerging digital printing technologies. Who would have thought ten years ago that rotary letterpress would be coming to the end of its life span? The typesetting industry also thought it was immune from extinction.

With a true seven-color digital system, we now have a much better opportunity to measure and control the ingredients and, most importantly, predict the outcome on press. Thousands of spot colors now can be simulated digitally using only seven process colors.

Clean oranges, saturated reds, deep blues, vivid greens...the list goes on. It's not rocket science to visualize the expanded color range now available.

Anilox rolls are locked in the press, because this digital mixing system simply layers color in the same way we paint a wall. For example, Pantone 485 red (another buyer's favorite) is reproduced digitally by overprinting 100% yellow, 100% magenta, and 100% process red with an 800 lpi @ 2.2 bcm. The total (layered) density will deliver around 1.80+ and the Delta E (variance) will be less than 2 across the entire run. Moreover, that 150-lpi vignette and fine reverse text can be reproduced adjacent to the 1.80 layered red.

Combination high-line screen and high-density solids are no longer a “flexo fantasy.”

Let's say you charge out your wide web press at $400/hr. With the implementation of CMYK+RGB inks (on one press alone), you could save $360,000/yr, simply by reducing 50% of your spot color wash-ups. For example:

| Wide web press | $400/hr |

| Manual spot color change | 20 min |

| No. colors per shift | 9 |

| Cost savings (300 days) | $360,000* |

| *This figure hasn't even taken into account the reduced anilox inventory, ink savings, and make-ready waste. | |

Which pocket you put the savings into is entirely up to you. How much you pass on to your customer is also up to you. Don't be greedy though...you know the saying, “Pigs get happy; hogs get slaughtered.”

So next time you run that analog spot color or swap out that anilox, stop and ask yourself, “Why am I doing this?” Your answer probably will be, “That's the way we've always done it.”

Maybe it's time we got off that treadmill and looked outside the box. A cost-effective “digital” way to reproduce color in print has finally arrived.

Remember, what separates you from your competitors is simply how you “bake that cake.” Constantly changing your (analog) ingredients will never get it to taste the same.

Matthew Bernasconi is the founder and technical director of Opaltone Graphic Solutions, the developers of Opaltone Seven Color Process. He can be reached at matthewb@opaltone.com.

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).