QC Electronics, Inc. – Corona Treatment Specialists

- Published: January 12, 2022

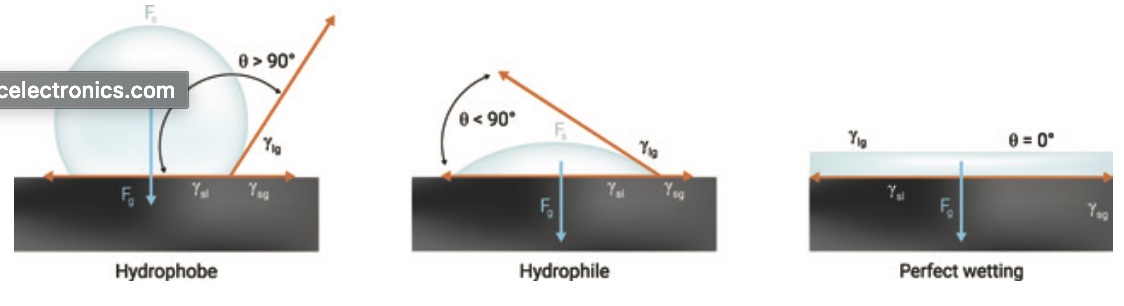

Corona treatment is a scientifically proven surface modification process that has been practiced in various forms for over 70 years. The object of surface treatment as a corona process is to render a typical plastic film or surface receptive to inks, glues, and coatings. The process is most widely known for its ability to improve the surface bonding characteristics of various materials.

Leaders In Reliability

QC Electronics, Inc. designs and manufactures a complete line of corona treatment equipment. We work closely with manufacturers including blown film, coaters, laminators, extruders, printers, and more to seamlessly integrate our systems with their production line. We also offer consulting and lab services through our in-house laboratory. QC is your one-stop-shop for all corona treatment needs.

The past few years, we have spent a lot of time rethinking and innovating our line of equipment. Our stations are now completely touch controlled and automated, allowing operators to finetune their corona treaters to deliver precise and even dyne levels consistently. A major new feature for 2022 is automatic air gap adjustment. This feature saves customers valuable time, increasing profitability.

As the only corona treatment equipment supplier that fabricates and manufactures a complete product line in-house, QC takes pride in offering customization and top-quality design at surprisingly reasonable prices. Compare the quality and workmanship of a QC Advantage Bare Roll Corona Treater against any other and you will understand why QC Electronics is known as the leader in reliability. QC corona treaters are designed to be installed and forgotten about to allow you to focus on your core business and make profits.

Power Supplies

QC’s power supply is unlike any other in the industry. Many companies seek out QC because we use SCR rather than IGBT technology. Last year, our NEXTGEN-i power supply went under a complete re-design. We developed the new design with a focus on new capabilities, longevity, and ease of operation in mind. The power supply is now controlled by an advanced operating platform using FPGA control. This allows the system to be more efficient and customer centric. The power supply is completely touch controlled; this allows you to access important operation information and run quick glance diagnostics.

Laboratory

All QC customers are granted access to QC’s surface analyzation lab and personalized reports free of charge. QC’s lab consists of a QC sheet corona treater, dyne testing utensils, and a state-of-the-art KRUSS surface analyzation device. The KRUSS surface analyzer provides extensive reports on the material’s wettability and molecular structure pre and post treatment. The device uses a microscope to measure and document the reaction the material experiences with water and diiodomethane. This helps QC customers better understand their material(s) and provides them the tools the present the most profitable product.

Throughout our 34 years of business, QC has established a promising global presence. We work closely with scientists of the industry, continuously educating ourselves of the industry’s innovations and discoveries with regards to the treatment of surfaces. QC is committed to studying the science behind surface adhesion and wettability to provide the highest quality, most efficient corona treaters available to the market.

Phone: (608) 742-1661

Website www.qcelectronics.com

Email: sales@qcelectronics.com