Static Beat | Dissipators Work Where Only 1 Side Has Static

- Published: September 21, 2015, By Dr. Kelly Robinson

Is it really necessary to install 2 static dissipators?

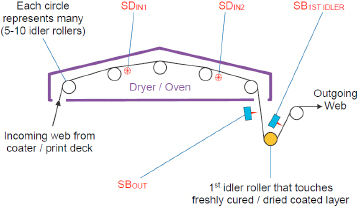

At the exit of the dryer/oven in Figure 1, I often recommend installing two static dissipators.

Well, is this really necessary? Am I just trying to get you to buy more stuff than you really need?

Before you throw me out, let me explain!

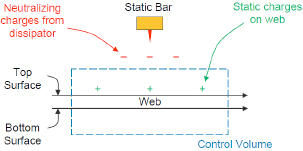

Both active and passive static dissipators work effectively only when one side of the web is charged. For example, the static dissipator in Figure 2 responds to the three static charges inside the control volume on the top surface of the web by providing three negative, neutralizing charges.

The three negative ions from the static bar move toward the three positive static charges on the web, and they deposit on the top surface. The web exits the control volume with all three charges on the top surface neutralized by ions from the static bar.

Our static bar has done a good job. A charge free web exits the static bar. Good!

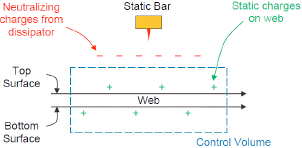

Now, look what happens when the web in Figure 3 enters the control volume with three static charges on the top surface and three static charges on the bottom surface. Our static bar responds to the six static charges on the web inside the control volume and provides six negative neutralizing charges. The six negative charges from the static bar move toward the six positive charges and deposit on the top surface of the web.

Of course, just like before, the three positive static charges on the top surface of the web are neutralized by three of the negative ions provided by the static bar. However, the three static charges on the bottom surface of the web are unchanged. The three negative, neutralizing ions from the static bar deposited on the top surface, not the bottom surface.

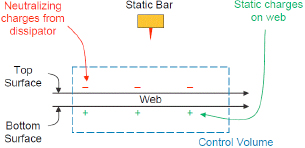

The web exits the control volume in Figure 4 with the three positive static charges on the bottom surface. Of course, they are unchanged because they are on the bottom surface and our static bar was installed facing the top surface. Note also that the web exits the control volume with the three negative, neutralizing ions from the static bar on the top surface.

The static bar in Figure 3 and Figure 4 neutralized only the static on the top surface facing the static bar. All of the static charges on the bottom surface pass the static bar unchanged. And, the static bar added negative ions to the top surface of the web.

Our static bar performs poorly. Rats.

This is why I recommend installing two static dissipators at the exit of a dryer/oven. Static dissipator SBOUT in Figure 1 neutralizes static charges deposited on the bottom surface of the web by the idler rollers inside the dryer/oven. We know that these static charges must be on the bottom surface of the web exiting the oven because no rollers touched the top surface.

Static bar SB1ST IDLER in Figure 1 neutralizes static charges deposited on the top surface of the web by the first idler roller that touched the freshly dried or cured layer. This first roller that touches the freshly dried or cured layer is a critical roller. The freshly dried or cured coating is often very active from a triboelectric charging perspective. And, the web exiting this roller can have very large amounts of static.

Static bars effectively neutralize static on the web surface facing the static bar. So, to achieve good static control, we must know which side of the web is charged when we install static bars.

I invite you to ask questions about this column and to suggest future topics. My email address is: Kelly.Robinson@ElectrostaticAnswers.com.

I invite you to ask questions about this column and to suggest future topics. My email address is: Kelly.Robinson@ElectrostaticAnswers.com.

Static control expert Dr. Kelly Robinson, president of Electrostatic Answers, has 27+ years of experience in problem-solving and consulting. Kelly writes PFFC's Static Beat column and the Kelly on Static blog. Contact him at 585-425-8158; kelly.robinson@electrostaticanswers.com; www.electrostaticanswers.com.