Static Control for Adhesive Lamination

- Published: August 15, 2019

Prevent static from becoming laminated inside a multi-layer web using best-practice static control.

By Kelly Robinson Ph.D., Owner at Electrostatic Answers

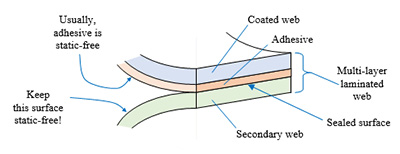

Figure 1: Keep the “sealed surface” static-free

The multi-layer web in Figure 1 performs better than a single-layer web. Printing on the “sealed surface” in Figure 1 is durable and scratch resistant. And, a thin barrier film laminated to inexpensive thicker web makes a strong packaging film that extends product shelf-life.

High-performance, multi-layer webs are often produced using adhesive lamination. Preventing static from becoming trapped inside is our main static control goal. To accomplish this goal, first identify each source of static charging. Then, use best-practice static control to neutralize static from each source.

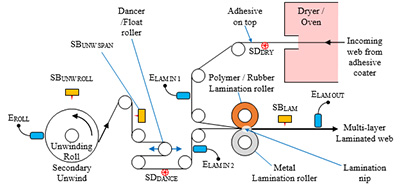

Figure 2: Adhesive laminator with five static controls

The multi-layer web is formed at the lamination nip in Figure 2. First, let’s look at the web exiting the Dryer / Oven. The adhesive surface exiting the Dryer / Oven is normally static-free. Once the adhesive is coated, the surface of the adhesive touches nothing until lamination. So, the adhesive surface is normally not a problem.

However, the back, uncoated surface exiting the Dryer / Oven in Figure 2 likely carries static from touching the hot, idler rollers. The best practice is to dissipate static on the web exiting a dryer or oven (see Static Beat | Control Static on Insulating Webs in Dryers). This uncoated web surface will be exposed after lamination. So, while static control is recommended, we can use an economical passive dissipator.

Install passive static dissipator SDDRY in Figure 2 on a web span exiting the Oven / Dryer facing the uncoated web surface that touched the hot idler rollers. This static dissipator may be a passive static dissipator (see Static Beat | How Do Passive Dissipators Neutralize Static?).

Verify that the web exiting the Dryer / Oven carries low static by measuring ELAM IN 1 in Figure 2 using a hand-held electrostatic fieldmeter (see Static Beat | Assess Static Risks Using Electric Fields). The average fieldmeter reading should not exceed ±5 KV/in.

The secondary web in Figure 1 is usually the problem. Any static on the “sealed surface” of the web from the secondary unwind will be trapped inside by lamination. Once static is sealed by lamination, it cannot escape. This static will be present in the web for the life of the product. So, preventing this static from becoming trapped inside the web is our main goal for lamination static control.

An unwinding roll can store a large amount of static from the process where the roll was wound. The best practice is to use two powered static bars to dissipate static on both sides of the web exiting an unwinding roll (see Static Beat | Unwinding Static).

Install powered static bar SBUNW ROLL in Figure 2 to dissipate static on the outside surface of the unwinding roll. This static bar should be a long-range, pulsed DC static bar so that good neutralization efficiency is maintained (see Static Beat | Static Dissipator Neutralization Efficiency) as the roll diameter decreases.

Verify that SBUNW ROLL functions properly by measuring EROLL in Figure 2 using a hand-held electrostatic fieldmeter (see Static Beat | Assess Static Risks Using Electric Fields). The reading should not exceed ±15 KV/in.

Install powered static bar SBUNW SPAN in Figure 2 to dissipate static on the inside surface of the web exiting the unwinding roll. This static bar should be short-range static bar installed after the first fixed idler roller facing the inside surface of the web roll (see Static Beat | Unwinding Static).

Dancers or Float Rollers can deposit a significant amount of static on the web surface that touches the moving roller. The best practice is to dissipate static on a web exiting a dancer or float roller. The web surface that touches the Dancer or Float roller in Figure 2 is the bottom surface of the web that will be exposed after lamination. So, while static control is recommended, we can use an economical passive dissipator.

Install passive static dissipator SDDANCE in Figure 2 on a web span after exiting the Dancer or Float Roller facing the web surface that touched the moving roller. This static dissipator may be a passive static dissipator (see Static Beat | How Do Passive Dissipators Neutralize Static?).

Verify that the web from the secondary unwind carries low static by measuring ELAM IN 2 in Figure 2 using a hand-held electrostatic fieldmeter (see Static Beat | Assess Static Risks Using Electric Fields). The average fieldmeter reading should not exceed ±5 KV/in.

The Polymer / Rubber Lamination roller in Figure 2 can deposit a large amount of static on the web. The best practice is to dissipate static on a web exiting a lamination nip.

Install powered static bar SBLAM in Figure 2 on the web span exiting the lamination nip facing the web surface that touched the Polymer / Rubber Lamination Roller. This static bar should be short-range static bar installed to maximize its neutralization efficiency (see Static Beat | Static Dissipator Neutralization Efficiency).

Finally, verify that the Multi-layer Laminated web exiting our process carries low static by measuring ELAM OUT in Figure 2 using a hand-held electrostatic fieldmeter (see Static Beat | Assess Static Risks Using Electric Fields). Exiting a properly functioning powered static bar, the average fieldmeter reading should not exceed ±2 KV/in.

The over-arching static control goal for lamination is to prevent static charges from becoming sealed inside the web. Practice good static control and follow best practices to achieve this goal. Verify that static is well controlled using a hand-held electrostatic fieldmeter. In general, static readings should not exceed ±5 KV/in.