Laser Cutting for Automating the Cutting Process in Labels & Packaging Applications

- Published: October 28, 2024

By Steve Leibin, President, Matik, Inc.

In the fast-paced world of labels and packaging, precision, efficiency and versatility are paramount. Traditional cutting methods often struggle to keep up with the demands of modern production, leading to increased interest in laser cutting technology. This article delves into how laser cutting is revolutionizing the labels and packaging industry by automating the cutting process, its benefits and the future trends shaping this technology.

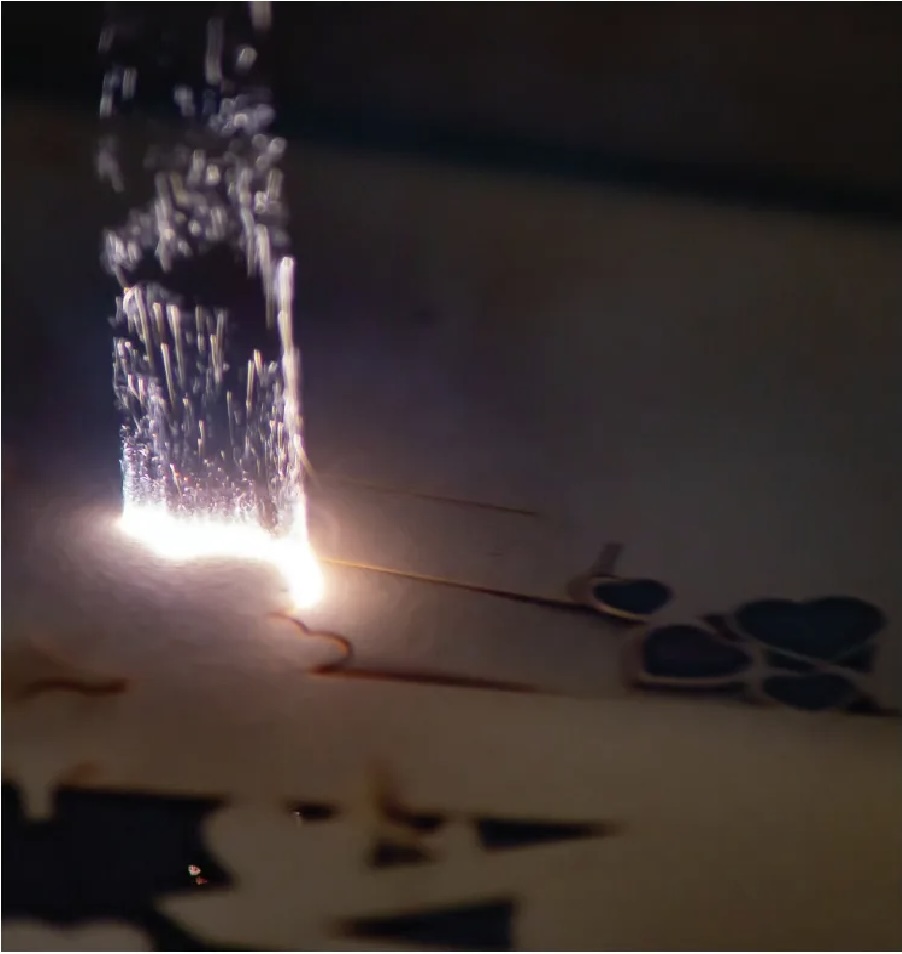

The Basics of Laser Cutting

Laser cutting uses a concentrated beam of light to cut or engrave materials. The laser's high intensity can cut through a variety of substances, including paper, cardboard, plastic and thin metals. This makes it an ideal choice for intricate and high-precision applications such as labels and packaging.

Automation in Laser Cutting for Labels & Packaging

Automation in laser cutting involves the integration of advanced software, robotics and control systems to manage the cutting process with minimal human intervention. This technological synergy enhances the speed, accuracy and consistency of cutting operations.

- Advanced Software: Software integration is critical in automating laser cutting. Design files created using Computer-Aided Design (CAD) software are directly fed into laser cutting machines. The software controls the laser's movements, ensuring precise cuts according to the design specifications.

- Robotic Handling: Robotics play a vital role in automating the material handling process. Robots can load and unload materials, position them accurately under the laser and sort finished products. This reduces manual labor and increases efficiency.

- Automated Quality Control: Automated systems equipped with sensors and cameras monitor the cutting process in real-time. They ensure that the cuts meet the required quality standards, immediately identifying and correcting any deviations.

Benefits of Laser Cutting Automation in Labels & Packaging

- High Precision: Laser cutting offers unparalleled precision, which is crucial for producing detailed and intricate designs on labels and packaging. Automated systems ensure consistency across large production runs.

- Flexibility: Laser cutting can easily handle various materials and thicknesses, making it highly adaptable for different labeling and packaging needs. Changes in design can be implemented quickly without the need for new tooling.

- Speed and Efficiency: Automation significantly speeds up the cutting process. Continuous operation with minimal downtime boosts productivity, meeting high-volume demands effectively.

- Cost-Effectiveness: By reducing material waste and minimizing labor costs, automated laser cutting is economically advantageous. The precision of laser cutting also means less material is wasted, further reducing costs.

- Customization and Personalization: The ability to quickly change designs allows for high levels of customization and personalization in labels and packaging, catering to market trends and consumer preferences.

Applications in Labels & Packaging

- Product Labels: Laser cutting is ideal for creating high-quality, detailed labels for various products. The precision ensures clean edges and intricate designs, enhancing the overall appearance of the product.

- Custom Packaging: Unique packaging designs can be created with ease, helping brands stand out in a competitive market. Laser cutting allows for the creation of complex shapes and patterns that are difficult to achieve with traditional methods.

- Security Labels: For industries requiring anti-counterfeit measures, laser cutting can produce complex security labels with microtext and other intricate features that are hard to replicate.

- Promotional Materials: Laser cutting is used to create eye-catching promotional packaging and labels that attract consumer attention and enhance brand visibility.

Future Trends in Laser Cutting Automation

- Artificial Intelligence (AI): Al is poised to further enhance laser cutting automation. Al algorithms can optimize cutting paths, predict maintenance needs and improve overall efficiency through data analysis.

- Sustainability: As sustainability becomes a priority, future advancements in laser cutting will focus on reducing energy consumption and material waste, making the process more environmentally friendly.

- Integration with loT: The Internet of Things (loT) will enable laser cutting machines to communicate with other devices and systems, creating a more interconnected and efficient production environment.

- Enhanced Customization: Advances in laser cutting technology will continue to support the trend towards greater customization and personalization in labels and packaging, meeting the growing consumer demand for unique and tailored products.

Conclusion

Laser cutting automation is transforming the labels and packaging industry by providing a high level of precision, efficiency and flexibility. As technology continues to evolve, the integration of AI, IoT and sustainability initiatives will further enhance the capabilities and applications of laser cutting. This revolution in manufacturing is poised to meet the ever-changing demands of the market, delivering high-quality, customized solutions for labels and packaging.

About the Author

Steve Leibin has served within the packaging industry since 2001. During his time with Matik, he has progressed from area sales manager to his current position as president. Leibin is responsible for strategic planning and day-to-day management of the company, which has offered solutions for the converting, label, folding carton, commercial printing and security markets in North America for more than 40 years.