Handle Unsupported Film Without Stretching

- Published: March 01, 2009, By Edited by Edward Boyle, Contributing Editor

Hally Labels is headquartered more than 7,500 miles from the nearest US converter, but the Australian-based label printer apparently faces many of the same challenges as its North American counterparts. “With its tight margins and excess capacity on label presses across the region, staying ahead of the competition in Australia and New Zealand's label printing industry requires strong market knowledge and a good capital equipment strategy,” says Mike Haworth, finance director of Hally Labels.

The 43-year-old family-owned label converter was established in Auckland, New Zealand, and later expanded to Brisbane, Australia. Today it employs a total of 200 people in both locations, with sales offices now also in Sydney and Melbourne.

“Each site has its area of expertise,” says Haworth. “Auckland produces wine labels, and in Brisbane, we're doing higher-quality prime work, unsupported films, and meat labels.”

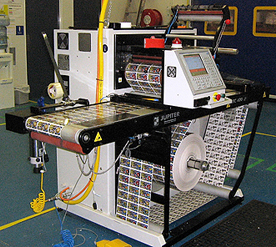

To do so, the company utilizes the latest in converting equipment, including 14 Gallus narrow web flexographic presses with letterpress, silk screen, water-based, and ultraviolet flexo technologies. The company's latest capital investment is a Prati Jupiter TC400 slitter/rewinder inspection machine, which was installed at the Brisbane facility. The company wanted to upgrade its slitting and rewinding capacities to handle thinner substrates without stretching.

The Jupiter TC4 actually was recommended by Gallus after Hally failed in its attempt to upgrade one of its existing slitter inspection machines. Using the Jupiter TC400, Haley Labels now can convert substrates ranging from flexible packaging to cardboard and from paper labels to booklets.

“We were looking for something that could run faster, but we had very specific requirements around the unsupported webs, using very thin films, and trying to run them at speeds without any stretch or tension issues,” explains Haworth, who visited Prati's Italian headquarters to see slitter inspection equipment in operation.

“We spent some time looking at the Jupiter TC400 and trialing material we had brought with us. When we came back, we decided we should have one.”

Enhanced Productivity

“Unsupported film is used for wrapping around the product with glue-applied [labels],” explains Tania James, operations manager. “Stretched film distorts the printed images and also creates dispensing problems, as the eye marks used by the machine change position. But the software-controlled rewind tension measurements on the Jupiter TC400 keep the material in constant web tension, preventing this stretching.”

The Jupiter TC400 has three rewind tension measurements, keeping constant web tension. It also inspects for missing labels and waste, presenting all defects at the correction table. While rewinding, a constant tension on the shaft and variable tension on the substrate prevents conic distortion on the roll.

“The other aspect for us was the ability to present cleanly finished and edged rolls,” says James. “Unsupported film has a tendency to take a variable web path because it is so light. On non-servo machines, you get a feathering of the edges on finished rolls. But with the Jupiter, Prati has been able to develop a smooth edge.”

James estimates that since the Jupiter TC400 began operation, production speeds have increased by 30%-40%, which enhances productivity downstream. “It also handles the more difficult jobs we had trouble with before, such as perforations,” adds Haworth. “Because of the good tension controls on the machine, we can process them a lot faster as well.”

Contributing Editor Edward Boyle, based in Reading, PA, has covered the converting industry for more than 24 years. Contact him at EJB Communications; 610-670-4680; ejbcomm@aol.com.

Converter Info

- Hally Labels Ltd. | 28 Limestone St., Darra, QLD 4076 Brisbane, Australia | +61 07 3712 0999 | www.hally.com.au

Supplier Info

- Prati srl | www.praticompany.com

PFFC-ASAP 314 - Gallus Group| www.gallus.org

PFFC-ASAP 315