Cold Foil | How To Be Successful When Choosing a Vendor

- Published: November 02, 2017, By Mike King and Toni McQuilken

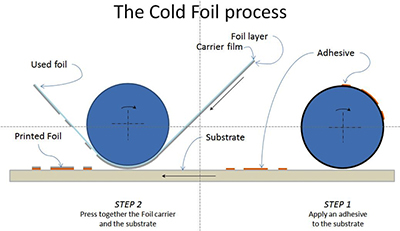

As the application opportunities expand, consider adding cold foil to your operations.

O ne of the things that really keeps me up at night is the amount of incorrect information in our industry concerning foiling applications and the foiling process. Too often, especially when it comes to cold foil applications, people just aren’t doing their homework and due diligence, so they aren’t getting the full picture. It is time to change that.

ne of the things that really keeps me up at night is the amount of incorrect information in our industry concerning foiling applications and the foiling process. Too often, especially when it comes to cold foil applications, people just aren’t doing their homework and due diligence, so they aren’t getting the full picture. It is time to change that.

Before you invest in a single machine or process, before you commit to a vendor, you need to make sure you know exactly what you are getting into. You need to understand the applications that will become available to you. And you need appreciate how critically important your vendor of choice will be to your success. It will be your partner that needs to meet all your needs — both now and well into the future.

Partnering Up Wisely

The steps to choosing the best cold foil vendor are common, yet often overlooked. I visit far too many service providers who skipped one or two, thinking they were unnecessary or too time consuming, only to pay a supreme price of both severe agony and bitter frustration. Take your time and follow each step:

1. Visit their facilities. First and foremost, you want to go, in person, to see what kind of facilities they are running. Don’t just go online, or use Google Earth to get a sense of the size of their factory. You want to know at what stage in the manufacturing process they are with cold foil. Have they been producing the equipment for years, or is this a new product line for them?

2. Ask for references. And not just one or two. If they say they have installations across the country, then make sure you have a sample of references that reflect that. Reach out to them, and ask to speak to the press room or operations manager. Find out what has gone right with the equipment — and what has gone wrong. Don’t take “NDA” for an answer — while there are always going to be a few companies that just don’t want their information shared, that list is usually less than 5% of any vendor’s business. So don’t let them deny you the references you need to make an informed decision.

3. Understand their service and support. What kind of customer support do they offer? Do they have local or regional offices, or just national? And do they just cover the equipment, or do they also offer a variety of other services that can help you build your business? You want to work with a company that wants to do more than just sell you something.

After Installation

Once you have chosen your vendor and installed your equipment, it’s time to start selling the capabilities. The applications for cold foil are literally endless. Packaging, in particular, is growing rapidly — most of these labels, boxes, bags, and other items are printed anyway. Adding a Cold Foil option, that can be applied right inline with the print, is an incredible opportunity. For an added 20 minutes to the run time of a job, you can add foils in any size, shape, or color imaginable — without hassle. Imagination is key to your success with cold foil.

Think about, for example, wine and liquor labels. Using cold foil on these pieces can create an amazing array of effects, but unlike with hot foil, which produces a flat “stamp” effect, with cold foil you can get an elegant look that follows the grain of the stock, and yet is perfectly integrated with the feel of that stock. When we say the grain of the stock, yes, we are speaking on uncoated linen type stocks. There are still numerous applications where that hot foil look is still appropriate; but hot foil is an art form and is more time consuming and costly all around. Cold foil is an alternative that can open the process up to far more projects, expanding your shop’s reach by a large margin.

Think outside the box for even more success

You can create effects like gradients, fine lines, reverses — anything down to just 3-point type without any problem at all. Litho press cold foil processes have made massive strides in recent years, exceeding what could be done with old processes in type sizes, registration, gradation, reverse outs, and more. In fact, some of these machines and technologies can now meet — or even exceed — hot foil brightness and shine, which was unheard of just a few years ago.

Do you need to open more doors to new business? If the answer is yes, then cold foil might be a good fit for you. Start researching the vendors, start talking to your customers, and start watching the creativity flow as you find new and innovative ways to make every single job you run stand out from the crowd. If you do your homework, cold foil can position you and your company in a whole new stratosphere of business success.

ABOUT THE AUTHOR

For now 42 years, Mike King, CEO/president and inventor of all Eagle Systems products, has specialized in the use of foil in printing. As chief design engineer of the company, King focuses upon the technological development of solutions that specifically are engineered to meet the quality and productivity needs of the printing industry. He prides himself on superior new-age engineering technology meshed with traditional customer-first support. His dedication to both the printing industry and the foil printing category is reason one why many consider him the foremost category expert.