Why is LED UV the next big thing for corrugated printing? Find out at AICC Annual Meeting

- Published: April 25, 2023

Baldwin to present greener, safer, productivity-boosting technology and debut “From Beast to Beauty” eBook

Packaging is no longer just the medium to get a product from point A to point B; it is also a company’s marketing, branding, and identity. For corrugated printers to keep up and stand out, LED UV technology might be the key.

Packaging is no longer just the medium to get a product from point A to point B; it is also a company’s marketing, branding, and identity. For corrugated printers to keep up and stand out, LED UV technology might be the key.

Baldwin Technology Co. Inc. — a one-stop source for high-performance treating, cleaning, curing, coating and inspection solutions — will make its case for its pioneering LED UV in corrugated at the 2023 AICC Independent Packaging Association Annual Meeting. The meeting will take place at Trump National Doral Resort in Miami, FL April 26.

Baldwin has also launched a new set of resources for corrugated packaging manufacturers, centered on a new eBook titled “From Beast to Beauty,” analyzing trends facing the corrugated industry. It kicks off the company’s new PrintEnomic$ resource center, which will house separate eBooks, industry organization and trade publication links, and a host of podcasts and instructional guides to maximize profitability in the corrugated, narrow web, and offset printing spaces.

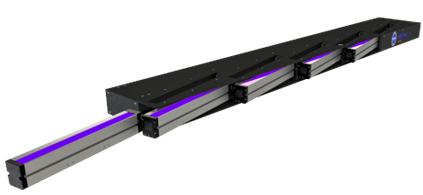

On Wednesday, April 26 during the Supplier Innovations session at 8 a.m., Baldwin regional sales manager, Bill Elting, will present a 6-minute overview of the company’s game changing XP Max LED-UV system. It is designed to cure especially wide substrates moving past it on a printing press, corrugated rotary die cutter, or manufacturing conveyor belt. Instead of one long LED array, XP Max uses numerous 20-inch (508mm) modules. These LED modules are set at an angle to allow for overlap of the LED emitting areas, forming a continuous UV curing array that spans any press or conveyor width needed.

The LED-UV modules within the XP Max system can significantly reduce energy and downtime costs while improving operational safety. LED-UV technology cures ink instantly with no drying time, using much less energy than both IR and arc UV. The modules can be turned on and off to cover only part of the conveyor, saving energy use when curing smaller stock widths. This arrangement also enables individual maintenance, allowing the removal of a single module without shutting down the full system for repairs. Lastly, the LED window temperatures are much cooler than both IR and arc UV, resulting in a much lower chance of fire when the corrugated substrate falls onto lamp heads.

“As Baldwin continues to expand our presence in the corrugated space, we are excited to showcase our products that will help converters provide a safer working environment for the team members, reduce press downtime through fully automated cleaning processes, and deliver higher quality output on the press,” said Baldwin Vice President of Sales Craig Black. “These all add up to a positive impact on bottom line profitability! We take the environment seriously and with the leading IR drying and LED-UV curing technology we guarantee significantly reduced energy consumption over traditional suppliers, and our cleaning systems drastically reduce water and solvent usage.”

For more information, visit baldwintech.com or bwforsyth.com.