The Versatility of UV Curing

- Published: December 16, 2022

By Jennifer Heathcote, VP Business Development, GEW

UV curing is a versatile technology that enables inks, coatings, adhesives and extrusions to be set inline, in a small footprint and at high speed while also producing performance properties superior to what is achievable with conventionally dried materials.

This is because UV curing is not drying and is instead a chemical reaction initiated with ultraviolet energy. A reaction of this nature creates strong bonds between molecules and drives the creation of long polymer chains. To the observer, UV curing instantly transforms liquid-like materials that are wet-to-the touch into crosslinked solid polymers that are fully dry-to the touch.

UV formulations are 100 percent solids, contain no liquid carriers that must be evaporated and require no energy-consuming thermal dryers. This means UV curing processes are more environmentally friendly and produce less waste.

Once a web or sheet exits a UV curing station, it is immediately ready for further processing, converting, sheeting, slitting, rewinding and shipping. This keeps work-in-progress goods out of inventory.

Finally, UV cured surfaces do not scratch, mar or become damaged when passed through downstream manufacturing line components or finishing equipment. This reduces scrap and facilitates quicker lead times.

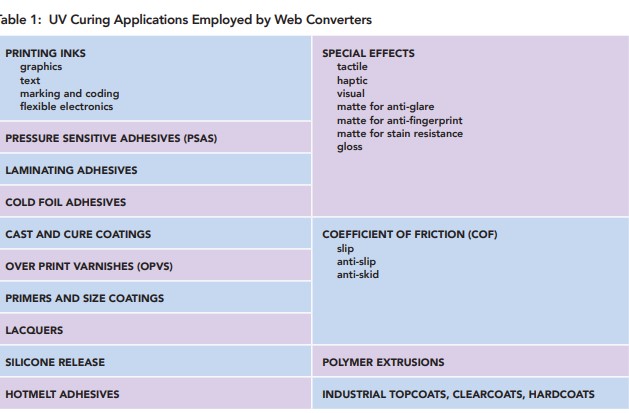

UV formulations are easily applied, cure in a fraction of a second and produce highly desirable and robust functional and aesthetic properties in final products. This facilitates use of UV processes across a wide range of printing, coating and converting applications. Examples are highlighted in Table 1.

UV Curing Sources

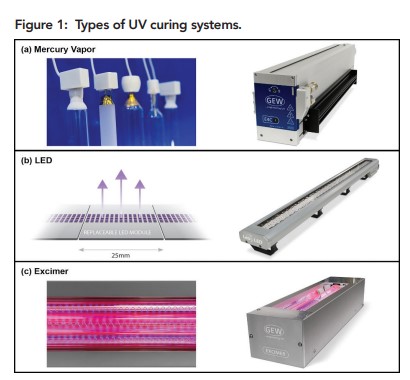

UV curing systems include mercury vapor, light emitting diode (LED) and excimer lamps. While each of these technologies emit ultraviolet energy, the mechanisms that generate UV energy, as well as characteristics of the corresponding UV output, are very different.

Mercury Vapor Lamps

Mercury vapor lamps are a type of medium-pressure, gas discharge lamp in which a small amount of elemental mercury and a specific mix of inert gas are vaporized into a plasma within a sealed quartz tube.

Plasma is a high-temperature ionized gas capable of conducting electricity. It is produced inside an arc lamp by applying an electrical voltage between two electrodes within a sealed quartz tube.

Once vaporized, mercury plasma generates broad-spectrum UV output that radiates 360 degrees from the lamp. Specially designed reflectors located behind the quartz tube are used to concentrate emitted UV energy onto webs, sheets or parts. UV curing systems utilizing mercury vapor lamps are cooled with forced air and/or circulated liquid. Mercury vapor lamps have a short warm-up and cool-down period that occurs each time they are switched on or off. An image of several mercury arc lamps and a lamphead assembly is provided in Figure 1 (a).

UV LED Lamps

LED lamps are solid-state electronics composed of numerous chips of thin, semi-conductive, crystalline materials electrically wired together in a single row or a combination of rows and columns. In the case of UV LEDs, precisely designed and fabricated gallium nitride (GaN) and aluminum, gallium, nitride (AlGaN) materials emit relatively narrow wavelength bands of ultraviolet energy when connected to a DC power source. The emitted light has a peak output centered at 365, 385, 395 or 405 nm, is projected forward from each LED a full 180 degrees, is quickly and easily turned on or off and has full linear adjustment of power. UV LEDs do not contain elemental mercury.

Each discrete LED is referred to as a positive-negative junction (p-n junction). This means that one portion of the LED has a positive charge, referred to as the anode (+). The other portion has a negative charge, referred to as the cathode (-).

When connected to a DC voltage power supply, free electrons in the n-type region cross over and fill vacancies in the p-type region. As electrons flow across the boundary, they transition to a state of lower energy.

The respective drop in energy is released from the semiconductor as a combination of UV photons and heat. The heat is due to electrical inefficiencies in the device. Typically, up to 40 percent of the differential is emitted as photons. The balance is converted into heat that must be removed from the system.

An illustration of three LED modules integrated into a much longer linear array with numerous modules as well as a corresponding lamphead assembly is provided in Figure 1 (b). Each of the purple squares in the graphic represents a single LED.

Engineers package and power LEDs to emit the desired UV output for the intended market segment and application. Lamphead assemblies are then cooled with forced air or circulated liquid to maintain the necessary device operating temperate, remove waste heat and ensure performance longevity.

Excimer Lamps

Like mercury vapor lamps, excimer lamps are a type of gas discharge lamp. Unlike broadband mercury vapor lamps, excimer lamps emit narrow bands of ultraviolet energy without the use of elemental mercury. Excimer lamps are commonly available with ultraviolet outputs centered at 172, 222, 308 and 351 nm. 172 nm excimer lamps fall between 100 and 200 nm which is known as vacuum UV (VUV).

The VUV band contains the shortest wavelengths of ultraviolet light. These wavelengths are entirely absorbed by oxygen and do not travel through air. As a result, when 172 and 222 nm excimer lamps are used for curing, they are always integrated with nitrogen inertion that pushes atmospheric air away from the gap between the lamp and curing surface and replaces it with nitrogen.

Another feature of wave lengths below 240 nm is that they generate ozone (O3) when absorbed by oxygen molecules (O2). Ozone generation is prevented through proper nitrogen inertion.

Photons of vacuum UV contain more energy than those of longer UV wavelengths but are only effective at curing the outermost surface of UV formulations. In fact, 172 nm wavelengths are completely absorbed within the first 10 to 200 nm of UV formulated chemistry.

As a result, 172 nm excimer lamps must always be integrated in combination with mercury or LED systems to achieve full depth of cure. Because the surface is crosslinked separately from the rest of the formulation, excimer UV curing is uniquely effective at creating matte surfaces that are anti-reflective, anti-glare and anti-fingerprint.

Excimer lamps consist of a quartz tube which serves as a dielectric barrier. The tube is filled with rare gases capable of forming excimer or exciplex molecules. Different gases produce different excited molecules and determine which specific wavelengths are emitted by the lamp.

A coiled electrode runs along the inside length of the quartz tube while ground electrodes run along the outside length. Voltage is pulsed into the lamp at high frequencies. This causes electrons to flow within the internal electrode and discharge across the gas mixture toward the external ground electrodes.

This scientific phenomenon is known as dielectric barrier discharge (DBD). As electrons travel through the gas, they interact with atoms and create energized or ionized species that produce excimer or exciplex molecules.

Excimer and exciplex molecules have an incredibly short life. As they decompose from an excited state to a ground state, a narrow band of photons are emitted. Excimer lamps generate negligible heat and require little if any lamphead assembly cooling. An image of an excimer lamp and corresponding lamphead is provided in Figure 1 (c).

UV curing is practical for inkjet, flexo, gravure, screen, rotary screen, litho, offset, slot-die, Mayer-rod, roller and curtain coaters, and spray among many other transfer and deposition methods. Mercury arc lamps are available in lengths up to 2.5 meters; LED UV lamps in lengths up to 1.7 meters; and excimer lamps in lengths up to 2.3 meters.

About the Author

As GEW’s VP Business Development, Jennifer Heathcote is a leading authority on conventional and UV LED technology, as well as their use across a broad range of industrial curing and graphic printing applications. To find out more about UV curing products and how they benefit printers, coaters and converters, visit www.gewuv.com.