Integrated Corona Treating System for Labs and Offline Production

- Published: March 03, 2022

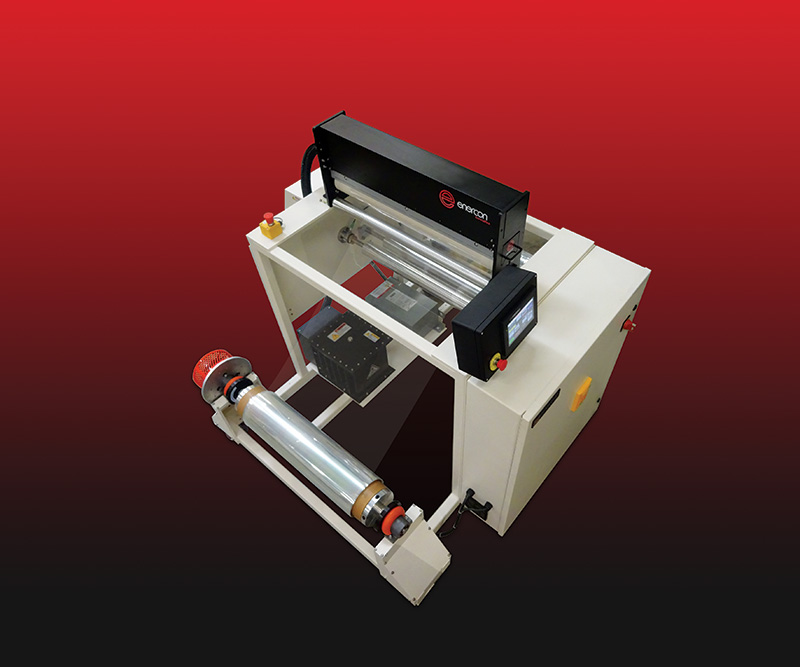

Enercon offers a fully integrated, turnkey corona treating system that improves surface energy of films for printing, coating and laminating. This free standing, offline surface treating system includes unwind, rewind, corona or plasma treater, power supply and high voltage transformer. The turnkey option is available for narrow web applications up to 32” wide featuring Enercon’s CoronaFlex for standard corona treating applications. The system is also available with Enercon’s Atmospheric Plasma3™ treater.

Enercon offers a fully integrated, turnkey corona treating system that improves surface energy of films for printing, coating and laminating. This free standing, offline surface treating system includes unwind, rewind, corona or plasma treater, power supply and high voltage transformer. The turnkey option is available for narrow web applications up to 32” wide featuring Enercon’s CoronaFlex for standard corona treating applications. The system is also available with Enercon’s Atmospheric Plasma3™ treater.

This treatment structure is an economical solution perfect for lab use as well as offline production when manufacturing limitations prevent inline treating. Deluxe options include web tension control that automatically adjusts as the roll diameters change. Plus, there is an option to change the motor speed to keep a constant line speed.

Both standard and deluxe systems feature a portable stand with an integrated cantilevered unwind, rewind design allowing for easy loading and unloading of material. The removable electrode cartridge locks into place for quick and easy changeovers. The plug and play design involves minimal start-up time and allows for easy installation. The system simply rolls into place, attaches to the exhaust, and plugs in.

Enercon Industries Corporation, headquartered in Menomonee Falls, WI, is a major manufacturer of equipment for the plastics, converting and packaging industries. The company supplies custom built corona and atmospheric plasma treating systems, as well as induction cap sealing systems.