Achieving Fluid Production: Controlling Static and Contamination

- Published: January 28, 2021

By Matt Fyffe, Vice President and General Manager, Meech USA

Companies in the label and packaging industry have come under serious pressure this year – unprecedented demand due to panic buying and stockpiling, production challenges due to social distancing requirements, staff shortages and supply chain issues have dominated the sector. With its critical presence in modern day life, helping to dramatically reduce food waste and protect products from contamination, flexible packaging’s seamless production and flawless quality control measures have never been more important.

Companies in the label and packaging industry have come under serious pressure this year – unprecedented demand due to panic buying and stockpiling, production challenges due to social distancing requirements, staff shortages and supply chain issues have dominated the sector. With its critical presence in modern day life, helping to dramatically reduce food waste and protect products from contamination, flexible packaging’s seamless production and flawless quality control measures have never been more important.

However, there are numerous threats that can impact upon the consistent, high quality delivery of products – one of which being static generation.

The threat to quality control

Static, when untreated, can cause web materials to become statically charged. This primarily happens when the web – paper, foil or film – is moving at high speed and can occur in a few ways; for example – through friction when the web makes contact with converting machinery, or through ‘separation’ – the unwinding of web rolls. Electricity from surrounding machinery can also lead to static generation through induction.

The presence of static can lead to a myriad of problems – contamination being one of the most significant. Static charges attract airborne dust and dirt to the web’s surface, potentially hindering the material’s final presentation but also greatly impacting on the hygiene of the finished product, which is almost guaranteed to be discarded before entering the next phase of production.

Statically charged webs can also impact on print performance; ink drops may be repelled away from the intended surface target, leading the print job to appear faded or blurry, affecting the overall appearance of the product.

But a web moving at speed can also become contaminated without static’s presence. This is caused by the ambient air that the web drags along when in motion – it creates a boundary layer that can trap debris within or beneath the surface of the layer. The faster the web moves, the thicker the layer becomes and the greater the chances of contamination.

Regardless of the cause, contaminated web materials can lead to higher levels of wastage, extended downtime and additional costs for maintenance repairs. Fortunately, there is sophisticated technology available in the shape of static control and web cleaning, which can counter the threats that static charges and contamination pose on packaging and labeling lines.

Static control

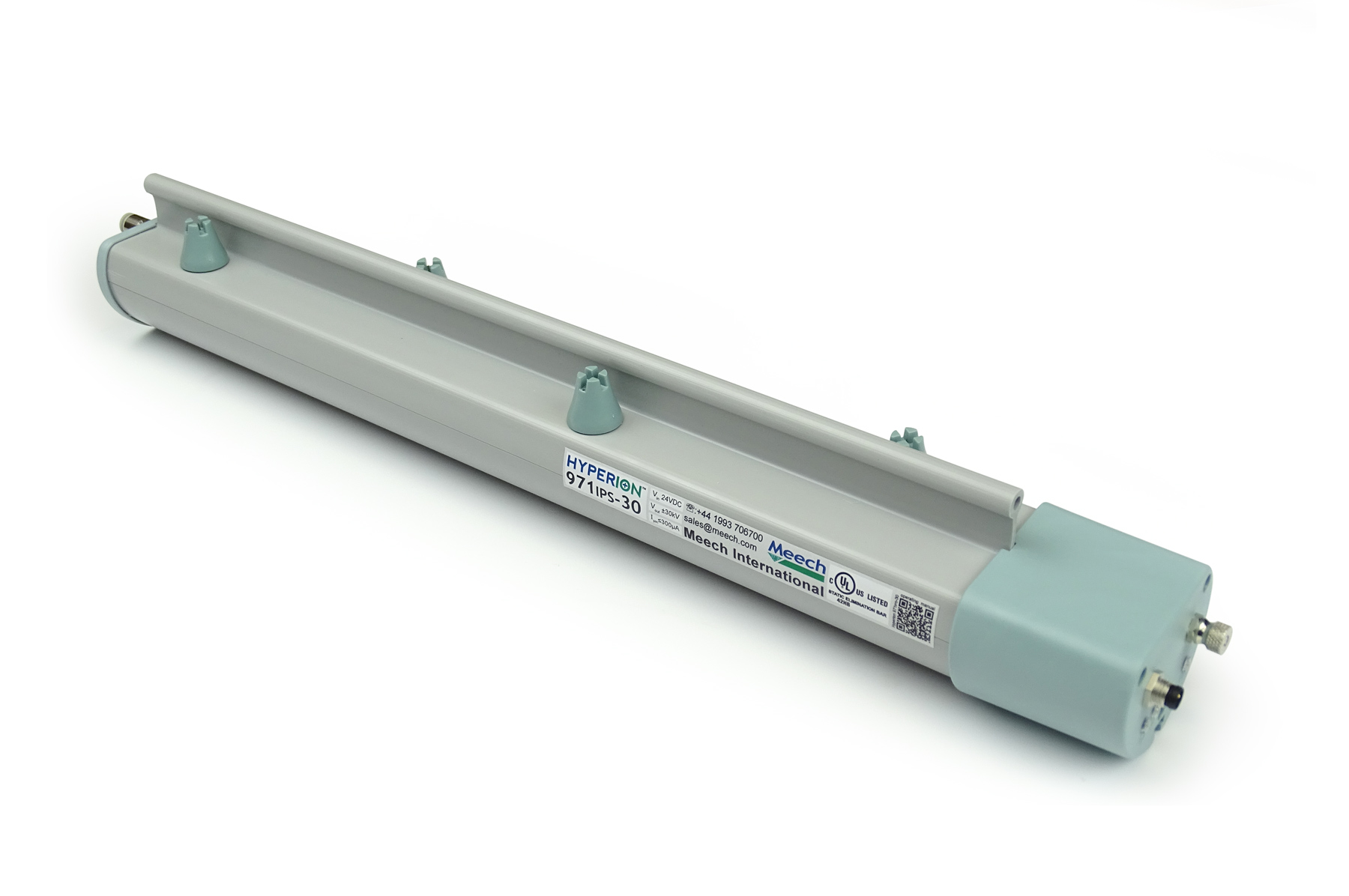

Designed to remove static from a moving web, static control uses ionization, where a voltage is fed to an array of emitter pins mounted on an ionizing bar, which releases a high-energy “cloud” of positive and negative ions. Any statically charged surface passing close to the cloud is quickly neutralized. Static control devices are a highly effective solution when installed just after the unwinding process and before the printing stage.

Today’s high advanced, modern static control products are designed for short, mid and long-range ionization. Suitable for fast-paced production environments, this technology is engineered to include monitoring technology as well as control over output voltage, frequency and balance.

Web Cleaning

Web Cleaning

Web cleaners act to effectively resolve contamination issues. Available in two forms – contact and non-contact – they are highly efficient at removing loose, dry debris from the web’s surface.

A contact cleaning system is suitable for slower, narrow web lines, such as those found in labeling. These cleaners incorporate twin elastomer contact rollers and perforated adhesive rolls which pick up and remove contamination from the web’s surface. While highly effective at removing low to moderately contaminated web materials, contact systems are not ideal for highly saturated webs.

Non-contact systems can remove all types of contamination from a variety of surfaces. Utilizing advanced computational fluid dynamics, non-contact systems subject the web to a strong but harmless force of turbulent air that breaks through the web boundary layer, releasing the contamination into the vacuum air flow, where it is removed.

Conclusion

Increased demand is likely to result in shorter turnaround times, which will lead to incremented production speeds. This can create problems on various parts of the line, impacting on flow and ongoing business costs.

Investing in equipment that can counter static charge and contamination will help companies keep up with the demands on their business and ensure the consistent manufacturing of high-quality label and packaging products.

About the Author:

Matt Fyffe, vice preside and general manager for Meech International, is responsible for all of Meech’s operations in the USA. Having joined Meech in 1994, he has developed a vast knowledge of the plastics, packaging, automotive, medical, converting, and electronics industries.