A Remedy for CD Buckles

- Published: July 24, 2020

By Timothy Walker, Contributing Writer

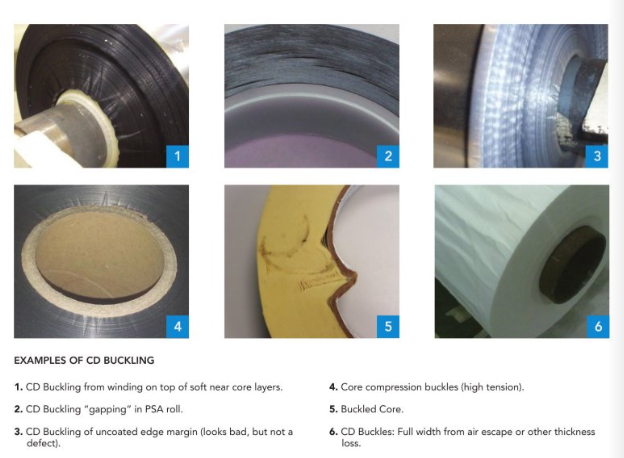

Washboarding. It sounds like a torture technique, but that water-boarding. Washboarding is a roll defect, technically called CD buckles. It’s when your roll feels like a washboard as you run your fingers around the surface, bump, bump, bump. Good for old-time cleaning your clothes by the creek, but bad for web products.

CD buckles develop under many product and process conditions, but all CD buckles share one common mechanism – layers within a roll are in machine direction (MD) compression.

When initially landing on a winding roll, webs start with machine direction (MD) tension and strain from the winding tension, T(initial), but over time they might lose tension and strain through several mechanisms, T(loss). As additional layers are added to a winding roll, the earlier layers may shift or compress down to a smaller radial position, giving up tension and strain. If the radial shifts are great enough, layers will transition from MD tension to compression.

Here are the recipes for preventing or creating CD buckles:

- If T(initial) – T(loss) > 0, no CD buckles; and

- If T(initial) – T(loss) < 0, CD buckles likely to form.

Winding conditions and web elasticity determine the initial tension and strain (or stretch) in the web as it lands on the winding roll. Other factors determine how much strain and tension is lost over time in the roll. When the tension or strain loss is greater than what the web started with, CD buckles quickly form.

The remedy for CD buckles is start with more tension or strain and lose less. Starting with more is easy, more center winding torque and / or more nip-induced tension. This might lead to other defects high tension defects, but your CD buckles will be gone. Reducing tension loss is the other remedy. This requires understanding the mechanics of rolls, but is a viable game plan.

How much compression is required to buckle the “laminated” layers of the roll is difficult to quantify, but any compression can lead to CD buckling. Sometimes the buckling will be initiated by a defect or discontinuity, such as the tape or step change of the roll’s first layer.

How much radial change within a roll is significant? The radial shifts that cause CD buckles are small, often less than 1mm (40 mils). If layers shift radially a percent similar to web strain from tension, it is a big change. For example, if PET winding tension creates 0.2 percent strain (i.e., each 1m of web is stretched 2mm), then a 0.2 percent radial decrease will release all this strain. Therefore, at 100mm (4-in.), only 200 microns (8 mils) of radial shift is needed to relieve the winding strain. For other products, this same shift could be minor or disastrous. For PE winding, where strain could be greater than 0.5 percent, this 0.2 percent radial shift loosens the roll, but does not cause buckling. In Al foil winding, were strain may be only 0.05 percent, a 0.2 percent radial shift will move the layers to negative 0.15 percent strain and have a great risk of CD buckles.

Most CD buckles are considered a “soft” roll defect from winding too loose. Low tension winding means less initial tension and strain. But CD buckles may also come from winding too tight, or too tightly for:

- Your wimpy core;

- Your wrinkled fluffy poor core start;

- Your lack of controlling air entrained in the roll;

- Your soft coated layers; or

- Your lack of tension control early in the roller winding.

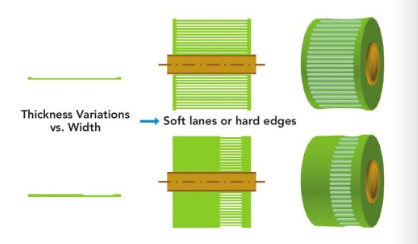

Also, you can do everything right and your softness is from your poor thickness profile, forming a good or tight roll structure where the web is thick, but a softness in the lanes of below average thickness.

If you want to stay out of debt, don’t spend more money than you have. To avoid CD buckles, start with tension or strain, that seems easy, but avoid all the ways you can lose it. Cores, thickness profile, winding upsets, core starts, uncontrolled air are all repeat offenders that steal your tension and strain leaving you and your customers with CD buckles in your rolls. Washboarding may not be illegal, but it will seem like torture to your profits.

About the Author:

Timothy J. Walker authors Web Lines, a column devoted to web handling, winding, guiding, rollers, and more. He has 35 years of experience in web handling processes, specializing in web handling education, process development and production problem solving. He can be reached at651.249.1121.