Cut With Glass

- Published: February 28, 2006, By Eldridge M. Mount III, EMMOUNT Technologies

Corona Treating

Polymer films—used for packaging and many industrial purposes—are made and combined in many locations around the world. In general, the films are manufactured from polymers such as polyester, polyamide (nylon), and polyolefins such as high-density polyethylene and polypropylene.

Polyolefin films are valued for their moisture barrier properties and are formed with a nonpolar surface. Polyolefins are wax-like materials with no oxygen or polar species in the polymer.

While the wax-like properties are very important, the nonpolar film surfaces are not receptive to ink or coatings (such as saran, laminating adhesives, or aluminum). Therefore, it is important that the film surface be converted into a polar surface so inks, coatings, and aluminum layers will wet and adhere to the film surface.

This surface treatment is done by oxidizing the film surface, which may be performed by several commercially available processes ranging from wet chemical attack, burning with a flame, or burning with an electrical corona discharge.

Over the years, many converters have chosen to use the corona discharge method because it is relatively simple to set up and operate. However, the corona treatment process is far from completely understood—not quite magic but sometimes seeming like it.

The corona treater functions by bombarding the film surface with electrons that create reactive, free radical sites on the film surface, which then react with oxygen from the atmosphere to create oxygen-containing functions on the film surface. This increases the film’s surface polarity and therefore its chemical receptivity for inks, coatings, and aluminum.

Treatment level is controlled primarily by the number of oxidized sites and a little by the carbon-oxygen functionality of the sites (alcohol (C-O-H), aldehyde and ketones (C=O), or acid (H-O-C=O) groups).

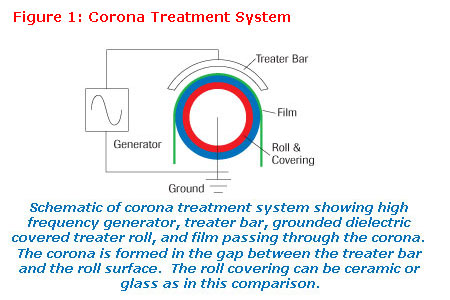

Corona treatment is a process in which high-frequency electrical energy is used to create a corona discharge within a narrow gap. This gap is formed between a conductive metal (usually aluminum) bar and a grounded nonconductive roll (Figure 1).

This forms a capacitive circuit in which the electrical energy is dissipated in the gap as an electrical discharge and is converted into gas plasma (called a barrier discharge) by ionizing the nitrogen/oxygen blend of the air.

In the treatment process, the film is passed over the surface of the roll and into the plasma discharge, where it is bombarded by electrons, ozone, and gas ions. The film surface is chemically modified (oxidized) as the electrons impact the polymer surface.

The oxidation process removes hydrogen ions from the polymer and produces free radicals on or near the film surface. The free radicals react with oxygen or moisture in the atmosphere, creating an oxygen radical, which then gives an oxygen function on the film surface.

A great deal of technical progress for corona treatment has been made over the years. Recent progress has focused on the design of high-frequency transformers and the improvement of power factors.

Many of the remaining unknowns regarding the operation of corona treaters are associated with the electrical properties of the treater roll and, more specifically, the treater roll covering.

Roll Covering

The dielectric roll covering forms the capacitive portion of the circuit, which controls the power dissipation in the treater. The roll covering not only must be nonconductive (making a capacitor) but also must be tough and durable to hold up to the mechanical rigors of the film converting process.

Contrary to intuitive thinking, the thinner the roll covering can be made, the better (higher) will be the capacitance of the roll, and therefore, the higher current density that can be applied to the treated surface at any given power level.

Because film surface treatment level depends primarily upon the number of oxidized sites on the film surface (i.e., the percentage of oxygen added to the film surface), it is possible to lower the power required to oxidize a specific number of surface sites if the capacitance of the roll is increased.

This is thought to be the basic mechanism of the improved electrical performance of the glass steel treater rolls. Better electrical properties of the glass permit thinner coatings, which generate higher capacitance rolls. Higher capacitance permits optimum film treatment levels at lower applied power.

This also results in the direct energy savings for the glass-covered roll relative to the ceramic roll, which was directly tested, and would be likely for thicker silicone, hypalon, or epoxy roll coatings as well. These same qualities of the glass treater roll allow for higher treater productivity by permitting an increase in line speed for the same treatment system. In essence, the glass coating permits a higher number of surface reactive sites to be produced by electron bombardment at any given power level by increasing the capacitance of the roll surface (its ability to accept charge). Because the treatment level depends on the total number of reactive sites produced, it is possible to achieve the proper number of oxidized sites on the film surface with lower power levels when using the glass covering.

Description of Measurable and Projected Savings

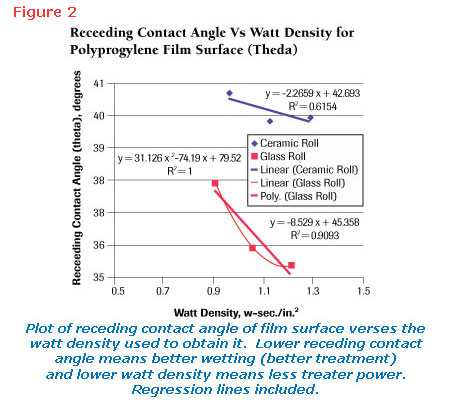

In reviewing the results for treating PP films as shown in Figure 2, testing indicates the glass treater roll can use far less energy to achieve any level of treatment relative to the ceramic roll that it replaced. The receding contact angle of 40 deg achieved by the ceramic roll is an acceptable target, as it was the normal operating point for the treated film.

Therefore, to determine the equivalent operating point for the glass roll to give a receding contact angle of 40 deg, the watt density for the glass roll can be estimated by extrapolating, to 40 deg, the linear or the second order regression result for the glass roll (see Formula 1).

| Formula 1 | |

|---|---|

| Receding contact angle=31.126 x WD - 74.19 x WD + 79.52 Receeding contact angle=-8.529 x WD + 45.358 Where WD=Watt Density watt-sec/in2 | R2=1 R2=0.9093 |

Extrapolating from the second order estimate finds, for a receding contact angle of 40 deg, an equivalent watt density value of 0.8 watt-sec/in.2 for the glass roll compared to the approximate value of 1.1 watt-sec/in.2 found from Figure 2 for the ceramic roll. This represents an energy savings for the glass roll of approximately 0.3 watt-sec/in.2 or approximately 27% relative to the ceramic roll.

Use of the linear regression would yield an even higher savings, but the second order regression results appear to be a more appropriate, conservative estimate in line with previous results of up to 40% energy reduction from commercial operations.

Therefore, using these watt density values, the approximate energy savings expected for a typical treatment process can be calculated using the energy requirement for the treated area from the line speed and film width times the watt density needed to treat that film area with each treater roll. Using the typical converting treater roll, the expected process conditions would be a treated roll width of 60 in. and a line speed of 500 fpm.

This yields a treated area of 6,000 in.2/sec, which would require 6,600 W (6.6 kW) for the corona treater. In comparison, the glass roll would consume 4,800 W (4.8 kW) to achieve the same level of film treatment.

If we assume a treatment process operating for 8,000 hr/yr (333 days), then the energy savings for a year of operation can be estimated for the glass roll relative to the ceramic treater roll as shown in Formula 2.

| Formula 2 |

|---|

| Ceramic rolls: (6.6 x 24) x 333=52,747.2 KW-hr Glass rolls: (4.8 x 24) x 333=38,361.6 KW-hr Total energy savings=14,385.6 KW-hr for the year |

The cost savings can be determined by multiplying the energy cost in a particular geographic area times the energy usage, and in this example, it would represent a cost savings of approximately 27% for the use of the glass-covered roll relative to the ceramic-coated roll.

In conclusion, direct experimental measurements indicate that glass-covered treater rolls create comparable film treatment levels at reduced power levels when directly compared to ceramic rolls. The lower power levels have several advantages over the ceramic rolls including the following:

- the reduction of energy costs due to lower power consumption at equivalent treatment levels;

- the potential for higher line speeds due to the lower power density required for equivalent treatment;

- an increase in the area of film that can be treated at the power limit of the treater.

A Study of Energy Savings In Corona Treatment of Packaging Films

During 2005, the New York State Energy Research and Development Authority (NYSERDA) funded a multi-client study of the electrical energy utilization of the corona treatment process. The purpose of the study was to detail the energy savings (up to 40% reported) previously found with replacement glass-coated dielectric rolls used in corona treaters.

During the study, an approximate 27% reduction in electrical energy use was found for treating polypropylene packaging films when compared to a conventional ceramic-coated dielectric roll.

The results of this study will be used by NYSERDA to promote this energy savings to all New York State converters, film manufacturers, or any other industry using corona treatment. The decrease in power utilization results in an improved film treatment process, delivering comparable treatment levels at lower power settings.

Based on the findings, a glassed steel treater roll can be used to lower energy costs or, conversely, to improve productivity by permitting higher line speeds through the treater.

The Treater Study was funded and overseen by NYSERDA, and the experimental measurements were defined and the analysis conducted by EMMOUNT Technologies. The film treatment experiments were conducted on an ExxonMobil film line using an existing corona treatment system (Figure 1) and its existing ceramic treater roll. The glass-covered treater roll was supplied by Empire Treater Rolls.

Films were made and treated on the ExxonMobil line at three power levels using both the ceramic and glass treater rolls. Treatment levels were determined by measuring the receding contact angle of water against the film surface. The results for homopolymer propylene films are shown in Figure 2 and clearly show an improved wettability for the films (lower contact angle) at all power levels for the glass-covered treater roll relative to the ceramic-covered roll.

The author would like to acknowledge the financial support of NYSERDA to make this study possible as well as the material support of Empire Treater Rolls and ExxonMobil Films Div. without which the study would not have been possible.

SUPPLIER INFO:

Exxon Mobile Films—oppfilms.com

Empire Treater Rolls—empiretreaterrolls.com

Eldridge M. Mount III is president of EMMOUNT Technologies, a consulting and training company located in Fairport, NY. Mount recieved an M.E. and Ph.D. in chemical engineering from Rensselaer Polytechnic Inst. and has more than 25 years of experience in extrusion processes and the manufacture, design, and metallization of oriented propylene and polyester films. He is the metallizing consultant for the Assn. of Industrial Metallizers, Coaters and Laminators (AIMCAL) and can be reached at 585/223-3996; emmount@earthlink.net; emmount-technologies.com.