Truth or Myth?

- Published: May 31, 2005, By Dr. Paul E. Gloor, Johnson Polymer LLC

Slide Angle

The tendency for package cartons to slide past each other can be an important property in many critical applications. This property often is measured and reported as the slide angle. Some methods of package handling rely on a certain amount of friction between cartons, so it is important for the printer/converter to control the amount of friction. This is critical—especially with today’s high-speed equipment.

The printer/converter and the package buyer need to understand the factors that influence the slide angle. There are two major facets of this property that come into play.

- Will the package perform properly during downstream processing, handling, and filling?

- Can the printer/converter measure and control slide angle to eliminate downstream problems?

Package printers often use aqueous coating to control the slide angle of their packages. These coatings are formulated to give the desired slide angle for their substrate, along with other esthetic and protective properties. However, there are other factors that come into play. This article presents work completed to understand slide angle control and measurement.

Conventional Wisdom or Fact?

There are many proposed theories that might influence the slide angle. We tested extensively to determine if these postulations are true.

Test Capability

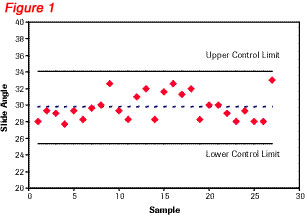

Truth or Myth? Some printers and their customers believe they maintain the slide angle within ±2 deg.

Myth. We tested more than 25 samples of printed beverage board under environmentally controlled conditions. We determined the measurement capability using the appropriate statistical techniques. The capability of the test under ideal conditions is about ±5 deg at best. It is not possible to control the slide angle within ±2 deg. See Figure 1.

Repeated Testing

Truth or Myth? It has been suggested the simple act of testing the slide angle of a sample repeatedly will cause the value to change.

Myth. We tested the same sample repeatedly and found that it does not harm the sample. It is possible to repeat the testing and obtain valid results within the test capability.

Coating Formulation

Truth or Myth? Formulators believe they control slide angle by using the correct polymers, resins, waxes, and additives. They attempt to formulate low, medium, and high slide angle coatings.

Truth. We tested the slide angle of board coated with different commercial coatings. Coating suppliers can formulate their products for low, medium, and high slide angles.

Coating Weight

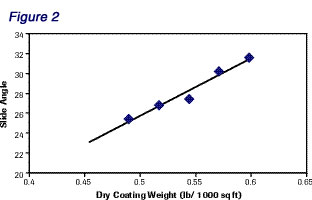

Truth or Myth? Printers suggest the slide angle changes as the amount of coating on the surface is changed.

Truth. We applied different dry coating weights and measured the slide angle. Figure 2 shows the coating weight can influence slide angle. However, a large change in coating weight is required to see significant changes in slide angle. It is best to choose the proper coating and maintain constant coating weight using a properly maintained anilox cylinder.

Coating Viscosity

Truth or Myth? Printers often manipulate the coating viscosity by adding water as an attempt to control the slide angle.

Myth. It is extremely difficult to manipulate slide angle by changing coating viscosity and solids. However, some printers try to change the slide angle by diluting the coating to change the coating weight. We measured Zahn viscosity as a function of solids and found that Zahn viscosity is very insensitive to solids at low solids levels but rises very quickly as solids increase in the higher solids range. Suppose we use an anilox that supplies a constant wet coating weight, and we adjust the viscosity and solids to change the dry coating weight. We can use the slide angle versus coating weight data (Figure 2) to predict the slide angle. Table I shows the predicted slide angle for the different viscosities. The typical press viscosity would range between about 18-30 sec Zahn #2. Therefore, changing the coating viscosity, within the limits of the printing press, results in a relatively small change in slide angle, especially when we consider the variation in the test method itself. For a practical change in viscosity, the coating weight change is too small to measurably affect the slide angle.

| Table 1 | |||

| Predicted slide angle as a function of coating viscosity and solids | |||

|---|---|---|---|

| Average Measured Viscosity (Zahn 2) | % Solids | Dry Coating Weight (lb/1000 sq ft) | Predicted Slide Angle (using figure 2) |

| Too high | 40.67 | 0.65 | 34±5° |

| 68.0 | 38.73 | 0.62 | 33±5° |

| 47.15 | 37.31 | 0.60 | 31±5° |

| 32.0 | 35.68 | 0.57 | 30±5° |

| 24.55 | 33.89 | 0.54 | 28±5° |

| 19.7 | 30.54 | 0.49 | 25±5° |

| 17.5 | 27.11 | 0.43 | 22±5° |

| 16 | 0 | 0 | |

| Source: Johnson Polymer | |||

Substrate

Truth or Myth? Throughout the packaging value chain, it is felt that different substrates have different slide angles, based on their surface roughness. They further suspect sheet-to-sheet variations.

Truth. We tested several substrates—including SBS (solid bleached sulfate), CCNB (clay coated news black), and coated kraft beverage board—and found different substrate types can give rise to different slide angles. However, we did not observe any sheet-to-sheet variations within the same substrate type. Therefore, given the variation in the slide angle test, it is probably reasonable to ignore sheet-to-sheet variations.

Ink Type or Coverage

Truth or Myth? Printers adjust ink based on job requirements. They believe coverage or different ink types might give rise to differing slide angles.

Myth. We compared slide angles for the same coating and substrate, with and without ink. We did not find any statistically significant difference between inked and non-inked board. Therefore, we believe the ink plays an insignificant role. Unusual print jobs or exceptionally heavy ink coverage might give rise to differing slide angles.

Environmental Conditions

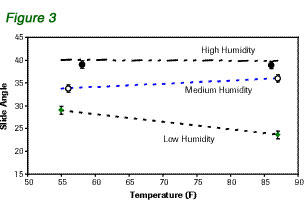

Truth or Myth? Some packagers believe ambient conditions, especially temperature and humidity, might affect slide angle during testing or throughout processing.

Truth. We tested several samples under various temperature and humidity conditions. Humidity is extremely important to the friction, but temperature appears to have no effect (see Figure 3). Remember that low temperature often is accompanied by low humidity. Therefore, when we find troubles in the winter, it probably is related to the humidity and not the temperature.

Package Age

Truth or Myth? Printers suggest anecdotal evidence that the slide angle can fall over time.

Myth. None of the coatings we tested showed a statistically significant change in slide angle over several weeks. We expect the slide angle to remain constant for a long time. We speculate that any observed changes in slide angle probably are attributable to changing environmental conditions.

Recommendations

Only rely on slide angle measurements from properly conditioned samples. The relative humidity has a large influence on slide angle. Any corrective actions based on unconditioned sample results probably will lead to even higher process variation and costs.

Consider the test capability when setting slide angle specifications. You cannot control slide angle within a narrower range than you can measure.

Not all coatings are created equal, so choose a quality coating and a reliable coating supplier. Changing suppliers can lead to inconsistent critical surface properties. Coating often is less than 2% of the total cost of a job. A potential coating cost savings may result in more scrap or a claim, which is not a savings in the long run. Select a coating with a slide angle in the proper range, but understand the package COF will change depending upon the environmental conditions. If low-friction packages present problems in dry conditions, select a coating with a higher slide angle.

Apply an appropriate coating weight; for example, 0.3 to 0.4 lb/1,000 sq ft (1.95 g/m2) is suggested as a minimum. Use a properly sized anilox type coater to apply the same wet coating weight each time. Clean the cylinder regularly to keep cells clear. Learn to measure coating weight and consider including coating weight measurements as part of your quality control program.

It is best to select coating with the proper slide angle and maintain a constant coating weight. We do not recommend trying to change slide angle by manipulating coating viscosity. Coating weight can be manipulated using the press conditions, including the proper choice of anilox cell volume4.

Environmental controls will help maintain consistency in the downstream cutting, folding, and filling processes. Let the cartons equilibrate for some time before processing them.

REFERENCES

1TAPPI T 815 om-95, "Coefficient of Static Friction (Slide Angle) of Packaging and Packaging Materials (Inclined Plane Method)."

2TAPPI Test Method T 816, "Coefficient of Static Friction of Corrugated and Solid Fiberboard (Horizontal Plane Method)."

3TAPPI TIP 0304-34, "Statistical Process Control: Friction—Slide Angle."

4P.E. Gloor, "Coating Control Quality and Paperboard Packaging" (Paper, Film and Foil Converter—May 2002)

SUPPLIER INFO:

Johnson Polymer—johnsonpolymer.com

Dr. Paul Gloor is technology manager of Johnson Polymer LLC, Sturtevant, WI, a producer of polymer styrene acrylic resins for use in the printing and packaging market. He has a Ph.D. in chemical engineering from McMaster Univ. He is a US patent holder and the author of several published papers. This is an abbreviated version of Dr. Gloor’s slide angle study. For more information, e-mail Americas@johnsonpolymer.com. The author would like to acknowledge the contributions of D. Miller, D. Shimkus, K. Young, D. Krawczak, and S. Jaszkowski to this work.

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).