Preparation=Die-Cutting Success

- Published: April 30, 2005, By Nsenga Byrd Thompson, Associate Editor

Product Focus

I admit to being a "do-it-yourself" junkie. However, in the past (okay, maybe as recently as last month), I fell into the trap of poor planning, especially when it came to selecting the proper tools for my project. In the converting world, the rules are the same: When it comes to selecting a die-cutting solution, poor planning is a trap you don’t want to fall into.

According to Gary Smith, VP–sales for RotoMetrics, Eureka, MO (rotometrics.com), converters must understand the types of jobs they are running before selecting a die-cutting solution. "Pre-planning the job that is to go on press is the best way to save time and money. If the converter can supply information up front, like the length of the run, the possible use of the tool in the future, what material is being cut, and how the finished product will be used, [suppliers] can make recommendations as to the type of tooling that is best-suited for the job."

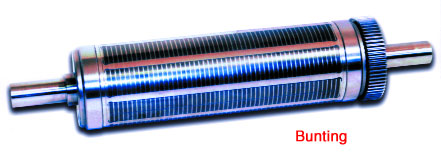

Along with assessing your needs, Tom Gray, printing products manager at Bunting Magnetics, Newton, KS (buntingmagnetics.com), recommends examining the manufacturing quality of the equipment and its substrate limitations.

Ken Pawlowski, director of digital products at Allen Datagraph Systems, Salem, NH (allendatagraph.com), focuses on ROI as a critical consideration. "Truly identifying the ‘need’ and coupling that with an accurate return on investment analysis [is a major consideration]," he says. "New equipment purchases need to be part of an overall marketing strategy or company-wide focus on customer satisfaction."

Beyond preparation, other considerations are precision, speed, and cost effectiveness. In today’s crunch to get it done fast, rotary applications have continued to grow in popularity. "Rotary applications save a tremendous amount of time, since they produce continuously with no stop and go," says Frank Rieder of HS Boyd Co., Tulsa, OK (hsboyd.com).

Within the folding carton industry, rotary die-cutting is becoming the process of choice, Smith explains. "We have seen a growing interest in converting folding cartons utilizing rotary dies. While this can be accomplished with both solid or flexible dies, converters generally are choosing solid dies due to ease of setup and simplified waste removal."

Gray adds that magnetic cylinders also play an important role for flexible die-cutting. He explains there are magnetic cylinders that have very low run-outs of 0.00008 in. that improve the life of the flexible die and are able to cut film labels of 1 mil on 1 mil.

Not surprisingly, digital solutions have created a definitive buzz. Explains Pawlowski, "Digital print platforms have evolved from ‘nice things to have’ to an accepted and necessary option, as customers are insisting on shorter runs and lead times. All of that digital print output is currently being converted on machines that require an old-fashioned analog die."

Pawlowski continues, "Digital technologies can transform a challenge into an opportunity. Digital die-cutting systems offer endless die shapes without the wait, cost, and limitations inherent with conventional tooling."

Digital die-cutting isn’t the only growing solution. Laser die-cutting, also known for its precision, quick changeovers, and cost savings (no tooling), has seen its star rise.

Keep a watchful eye for the continued growth of digital systems, Pawlowski says, especially all-inclusive digital systems that produce finished labels from raw stock. Rieder says small, relatively inexpensive rotary die-cutters for the digital markets, as well as laser technology, will increase in popularity.

And don’t forget RFID. Smith says suppliers will be working more closely with converters to develop specialty dies specifically aimed at RFID applications.

For now, careful planning and understanding your needs should help you sidestep the traps and achieve die-cutting success.

For this and other die cutting new products, see our May New Products.

Restrictions of time and space limit the number of companies, products, and trends that we can discuss in these reports. For additional information, see PFFC’s features and departments each month, consult the June Buyers Guide, and search our online archives.