Introduction to Roll Handling

- Published: April 30, 2005, By Jeff Damour, Converter Accessory Corp.

Web Exclusive

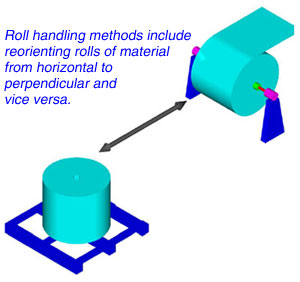

Roll handling is defined as the method in which rolls of material are transported and oriented prior to and after web processing. Film, paper, foil, textiles, and nonwovens are manufactured and wound on a core for further web processing or shipment to converters for further processing. Generally, rolls are wound parallel to the floor (horizontally). Most of the time, these rolls must be oriented perpendicular to the floor for roll storage or shipping.

Proper roll handling methods are required to ensure plant personnel safety and to minimize losses associated with roll damage.

Why is roll handling important to me?

According to OSHA Fact Sheet No. 89-09, back injuries are the nation’s #1 workplace safety problem. This fact sheet further states:

Moreover, though lifting, placing, carrying, holding, and lowering are involved in manual materials handling (the principal cause of compensable work injuries), the BLS survey shows that four out of five of these injuries were to the lower back and that three out of four occurred while the employee was lifting.

No approach has been found for totally eliminating back injuries caused by lifting, though it is felt that a substantial portion can be prevented by an effective control program and ergonomic design of work tasks.—OSHA Fact Sheet No. 89-09, pp.okstate.edu/ehs/training/oshaback.htm

There is no one specific weight limit for any particular activity. However, there are guidelines and formulas for determining acceptable lifting limits for specific activities. You can find these guidelines at: osha.gov/dts/osta/otm/otm_vii/otm_vii_1.html.

Employee safety is perhaps the most compelling reason for the proper utilization of roll handling methods and equipment. However, roll damage and subsequently wasted material can occur if proper roll handling methods and equipment are not incorporated.

How does roll handling equipment work?

There are many types of roll handling equipment from which to choose.

Truck devices | Clamp trucks are very common in applications where extremely heavy rolls of material need to be handled. These devices use powered clamps that close on the outside of the material roll diameter. They incorporate rugged designs for maximum life in harsh conditions.

The roll clamps can be designed to mount to the mast of any standard fork truck. They swivel to orient the rolls from horizontal to perpendicular and vice versa.

Clamp truck advantages:

- Can be designed to handle very heavy roll weights—up to 10,000 lbs

- Roll moving, turning, and possibly loading all in one unit

- Rugged design for demanding applications

- Easy to use

- Can handle multiple rolls at one time

- Mostly used in paper and board applications because of heavy roll weights common in that industry

- Very rigid roll handling (roll cannot sway in the air)

Clamp truck disadvantages:

- Clamping outside of roll may damage outside roll layers

- Not well suited for foils and films because of possible roll damage

- Not well suited for small diameter rolls or in applications where broad range of roll diameters is run

- Hydraulics require scheduled maintenance program

- Relatively expensive

- Limits the use of a fork truck—not practical to change from clamp to forks often

- When handling multiple rolls, all of the rolls must be the same diameter

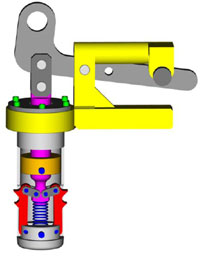

Another type of truck device uses a core probe, which is inserted inside a core of a roll of material. These devices have mechanically actuated teeth to grab the roll core.

Fork truck/core probe devices are used in lighter roll applications where damage to the outside of the roll is a concern. These devices can be designed to mount to the mast of any standard fork truck. The core probe pivots to orient the rolls from horizontal to perpendicular and vice versa.

There are two types of lift truck/core probe devices. The first includes a rigidly mounted probe and the second is a flexible mounted unit.

Truck/rigid core probe advantages:

- Simple design, easy to use

- Will handle multiple rolls with one probe

- Roll diameters may be different in multiple roll handling

- Can be designed with remote or mounted controls

- Probe can be powered (pivot) with electric, hydraulic, or pneumatic actuation

- Well suited for smaller rolls

- Well suited for applications where outside roll damage cannot be tolerated

- Roll moving, turning, loading, and unloading all in one device

- Roll is rigidly held in the air—no roll sway

Truck/rigid core probe disadvantages:

- Not well suited for roll weights over 2,000 lbs.

- Probe to core alignment is critical and can be difficult because of rigid probe mount

- May have trouble gripping metal or plastic cores

- Probe may damage cores

- Roll telescoping may be a problem with slippery webs or rolls wound loosely

- Additional vacuum plate may be required to eliminate roll telescoping

- Roll weight is cantilevered—could cause problems with heavy roll weights tipping fork truck

Truck/flexible core probe advantages:

- Simple design, easy to use

- Will handle multiple rolls with one probe

- Roll diameters may be different in multiple roll handling

- Can be designed with remote or mounted controls

- Probe is powered with electric hoist

- Well suited for smaller rolls

- Well suited for applications where outside roll damage cannot be tolerated

- Flexible point suspension allows easy probe alignment with core

- Roll moving, turning, loading, and unloading all with one unit

- Unit mounts on forks; fork truck is easily changed to roll handling unit and vice versa

- Roll weight is centered under forks, making the fork truck more stable

Truck/flexible core probe disadvantages:

- Not well suited for roll weights over 1,000 lbs.

- Flexible suspension system will allow roll to sway

- May have trouble gripping metal or plastic cores

- Probe may damage cores

- Roll telescoping may be a problem with slippery webs or rolls wound loosely

Overhead roll handling devices | Overhead roll handling systems are very common in all types of converting applications. Generally most overhead systems will handle up to 2,000-lb rolls of material. Most use core probes to grab the roll.

This type of roll handling device is mostly designed to operate with hoists mounted overhead. They swivel to orient the rolls north to south. Roll probes pivot to orient roll horizontal to perpendicular to horizontal.

Dual hoist overhead roll handling systems are relatively simple units. Their biggest advantage, compared to single hoist systems, is the ability to position rolls truly horizontal or perpendicular. The hoist supports being positioned in center (or beyond the center of the roll face) of the roll load allows true horizontal and vertical roll positioning. This true positioning ensures rolls are never damaged when placing them on the floor.

These units are not as stable as other single hoist systems. Added roll sway and instability is there biggest disadvantage when compared to single hoist systems. They also require two hoists to operate. North to south roll rotation must be accomplished with special tandem hoist frame designs.

Two electric hoists power dual hoist systems.

Single hoist over head roll handling systems are much more stable that dual hoist type. Their single point suspension supports heavy rolls in a much more stable fashion. These roll handling devices will operate with a lot less roll sway. They also require only one hoist so north to south roll rotation is possible with just one standard hoist.

Their biggest disadvantage is their inability to achieve true horizontal roll positioning when turning rolls. Since the single hoist support will never reach the midway point across the roll face, the roll will never reach true parallel positioning to the floor level. This could cause some roll damage since the "corner" of the roll face will touch the floor before the full width reaches floor level.

The pivoting probe within these units can be powered with an electric actuator, pneumatic cylinder, or hydraulic cylinder.

Overhead systems advantages:

- Relatively mechanically simple

- Can handle multiple widths with one probe

- Can be designed with remote pendants or mounted controls

- Well suited for rolls up to 2,000 lbs.

- Well suited for rolls where outside roll damage cannot be tolerated

- Roll oriented (perpendicular or horizontal) and moved or positioned at the same time

- Many units, designs, and styles to choose from

Overhead systems disadvantages:

- Not well suited for roll weights over 2,000 lbs.

- May have trouble gripping metal or plastic cores

- Probe may damage cores

- Roll telescoping is a concern—vacuum plate may be needed to combat telescoping

- Roll positioning is limited to overhead placement

Roll handling equipment is available to move rolls without orienting them. This equipment operates from overhead. These units use core probes with teeth to grip rolls that are perpendicular to the floor. Horizontal roll movers need probes and load leveling capability so the unit does not tip. Below are some examples:

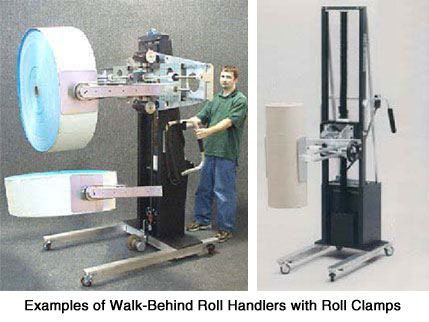

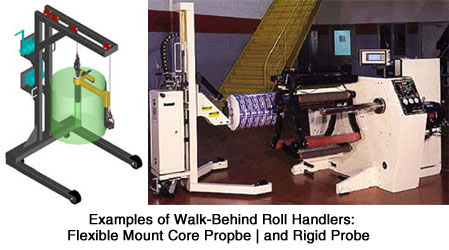

Walk-behind roll handling devices | Walk-behind roll handling systems are very common for use in light to medium roll weight applications. Generally most walk-behind systems will handle up to 1,000-lb rolls of material. However, there are designs available on the market to handle rolls up to 2,000 lbs. As we will see in the examples below, units that use probes or roll clamps are commonly available.

This type of roll handling device is self-contained and does not need any overhead equipment. These units will pickup, turn, move, load, and unload rolls of material.

Walk-behind/roll clamp systems advantages:

- Can handle multiple widths

- Can be designed with manual or powered operation

- Well suited for rolls up to 1000 lbs.

- Core material is not an issue—no damage to cores possible

- Move, turn, load, and unload rolls with a self contained unit

Walk-behind/roll clamp systems disadvantages:

- Not well suited for roll weights over 1,000 lbs.

- Clamps may damage some types of materials

- Roll diameters must all be the same for multiple roll applications

- Powered units need battery—will be out of service periodically for recharge

Walk-behind/core probe systems advantages:

- Can handle multiple widths with varying diameters

- Can be designed with manual or powered operation

- Well suited for rolls up to 1000 lbs.

- Move, turn, load, and unload rolls with a self-contained unit

- No roll damage to outer layers

Walk-behind / core probe systems disadvantages:

- Not well suited for roll weights over 1,000 lbs.

- Core probe may have trouble gripping metal or plastic cores

- Probe teeth may damage cores

- Rolls may telescope

- Powered units need battery—will be out of service periodically for recharge

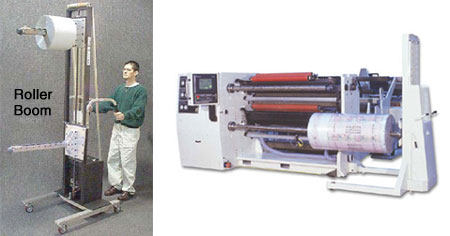

There are also several walk-behind devices for moving rolls that are oriented horizontally. These units do not have the ability to turn rolls. They are used for simply moving rolls and possible loading cantilevered shafts. Often times these units include ball bearings mounted in the boom for easy sliding onto cantilevered shafts of an unwind or from cantilevered shafts of a rewind stand. Units are available with powered roll pushers for heavy roll weights. Below are some examples:

Tilt table devices | Tilt tables allow users to turn rolls 90 deg. These tables can be designed to handle loads up to 10,000 lbs. They also can be loaded with whole pallets of rolls to turn several rolls at one time.

Tilt table advantages:

- Turn multiple rolls, even whole pallets, 90 deg all at one time

- Avoid telescoping

- Turn very heavy loads—up to 10,000 lbs.

Tilt table disadvantages:

- Rolls must be brought to and from tilt table

- Turning rolls is a separate operation from moving rolls

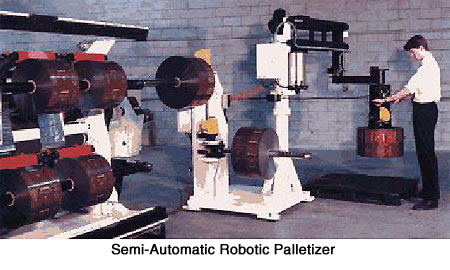

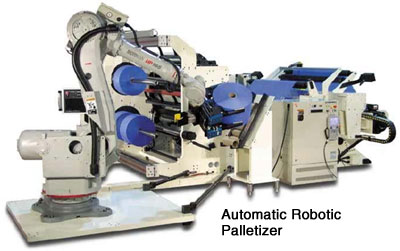

Automatic and semi-automatic robotic systems | Robotic systems offer the most automated roll handling systems. They remove or greatly limit plant personnel handling of rolls, offering the ultimate in safety.

Robotic systems advantages:

- Greatly reduce or eliminate operators from handling rolls

- Highly efficient

Robotic systems disadvantages:

- Very complex systems

- Changes in setups require changes in programming

- Expensive

What to consider when searching for roll handling equipment

There are many types of roll handling equipment. Each is well suited for specific applications and each is somewhat customized for specific applications.

In order to properly specify the right roll handling equipment for your application, there is some application information to consider and discuss with potential equipment vendors.

- How heavy are the rolls to be handled?

- Do you need to move rolls, turn rolls, or both?

- What roll widths are you handling?

- What roll diameters do you want to handle—minimum to maximum?

- What is your roll core size(s)?

- Are your cores cardboard, metal, or plastic?

- Are the outside layers of your material roll delicate?

- Will core damage effect your operations?

- What efficiencies do you need?

- How fast do you need to move rolls?

- How fast do you need to turn rolls?

- Do you require overhead? Or does it exist?

- Get everyone involved in the decision process! If equipment operators can’t use the equipment because it is too slow or cumbersome—they will not use it!

Roll handling equipment, when applied properly, will improve your plant safety and your bottom line. Less plant personnel injury, fatigue, and less waste due to roll damage will improve your process and increase profits.

Jeff Damour is engineering manager at Converter Accessory Corp., Wind Gap, PA. He has been with CAC for more than 19 years, most of that time spent "in the field." Jeff has published several web handling technical articles and is a regular presenter at the Converting Equipment Mfrs. Assn. (CEMA) Coating & Laminating and Slitting seminars. Contact Jeff at 800/433-2413; damour@epix.net.