Converting Industry News, Part 1

- Published: February 28, 2005, By Edited by Deborah Donberg

Covering the Full Spectrum of Industry News, Events & Activities

Part 1 | Part 2

EUROTALK

by Corey M. Reardon, AWA Alexander Watson Assoc.

Defining Release Liners

The European release liner and label industry is waiting with some trepidation to hear the results—believed to be imminent—of the EU’s decision on the nature of release liner: Is it process waste, or is it packaging waste? The decision may be known by the time this article is published.

If release liner is defined as packaging waste, it will be subject to the same conditions and financial implications as other packaging materials, per the EU Directive on Packaging and Packaging Waste. This would compound the industry’s existing problems: As I have highlighted before in this column, it is proving difficult enough to set up environmentally responsible waste management for release liners across the EU. With raw material prices rising, aggressive end-user purchasing and resulting margin pressures, and the threat from alternative labeling technologies that do not use release liner, this is a challenging time for the industry, particularly as it also is suffering from lack of capacity, particularly in paper liners, and critically, in glassines—Europe’s preferred choice for reel-fed labels, with a market share of 82%.

However, there is new investment in the market, although the current lack of supply will continue until next year at least. UPM’s investment in a rebuild of one of its two release base paper machine at its Tervasaari mill in Finland will bring to the market an expected 45,000 tonnes of additional capacity per annum. And, after filing for bankruptcy administration three years ago, Italy’s Ermolli Group is now once again successfully back in production providing badly needed capacity.

However, this may not be sufficient to provide more than a buffer that will help meet current market demands. With self-adhesive label market growth, particularly in Asia, a key export market for European glassine producers, supply will struggle to keep up with demand.

Although film liners represent just 3% of current market demand, the tight capacity in glassine could contribute to increased growth in film liner usage. If the EU Packaging Waste Directive classifies release liners as packaging waste, paper liners will face an additional challenge: Film liners are less problematical to recycle, and they offer a highly effective "second life" when recycled.

AWA Alexander Watson Assoc. is an international market research consultant company for the converting and packaging industries.

Pods Please, Coffee Purists

A coffee pod, designed to make one cup of coffee in about a minute, is a measured portion of ground coffee compressed between two sheets of biodegradable paper. Sonoco is supplying the packaging for a new line of these pods from Community Coffee.

Sonoco supplies coffee company with a high-barrier PET/foil/LLDPE laminated structured designed to protect the rich taste and aroma of the ground roast coffees. The pods are printed rotogravure to enhance Community’s red and black graphics and strong branding. Community converts the material and fills the pods with f/f/s equipment. Finished pods are packed in a specially designed dispensing carton containing 14 pods.

Ray Cate, general manager-new products at Community Coffee, says, "Consumers using pod packs expect the same rich flavor and aroma of a traditionally brewed cup of [our] coffee. We looked to Sonoco to supply a package that would protect the integrity of the coffee and our brand. They have succeeded on both counts."

Community is marketing the pod packs, which are compatible with several types of pod coffee makers, for food service use throughout the South and Southeast.

SUPPLIER INFO:

Sonoco—sonoco.com

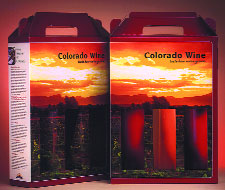

Colorado Wine

When Steve Warneke, president of Warneke Paper Box, Denver, CO, saw the carton intended for promotional use by The Colorado Wine Industry Development Board, he knew the laminated e-flute packaging wasn’t working, visually. He also knew what would work: Forte 36-pt, solid-fiber board from MeadWestvaco Packaging Resources Group.

Warneke had experience with the substrate, which combines a bright-white coated facing stock with a kraft board. He prepared printed carton samples for the Board, who liked the look but were concerned about giving up the strength of e-flute.

"We did a side-by-side comparison of Forte and mini-flute," Warneke says, "and proved Forte was just as good at preventing breakage." The Board was sold.

Warneke Paper Box prints the packages on a Heidelberg 102CD six-color, 40-in. offset press and die-cuts them on a Bobst die-cutter.

According to Steve Warneke, despite Forte’s thickness, it requires no additional set-up time and performs consistently at high speeds. The paperboard’s design, he adds, inhibits curl and wave.

The wine packages are being used for local wineries to display their merchandise and to sell take-home, mix-and-match three-packs of wine.

SUPPLIER INFO:

MeadWestvaco Corp.—meadwestvaco.com

Heidelberg USA—us.heidelberg.com

Bobst Group USA—bobstgroup.com

Inflatable Packaging Provides a Cushion

Pactiv, Lake Forest, IL, announces 9000 Air-Paq, engineered inflatable packaging said to be a durable, resilient, and efficient solution available in 2D and 3D shapes.

The patented design features a series of adjoining air tubes that are securely inflated to cushion and protect lightweight products during shipment. The tubes are connected via a series of patented one-way valves. If one chamber is punctured, the others remain inflated.

SUPPLIER NEWS

Lab Extrusion Line Running

GREENFIELD, MA—Argotec announces the startup of its new blown film laboratory extrusion line. Identical in function to the company’s full-sized blown film line, the lab extruder allows Argotec to run smaller test batches prior to committing customers to the expense of a full production run.

The lab line can produce thermoplastic film in thicknesses ranging from 0.8–20 mils, widths of 12l26 in., and lengths to 100 ft.

Among the uses for the line will be generating short-run film concept samples for customers; testing the processability and physical characteristics of new film formulations; and performing preliminary tests of new product offerings from resin suppliers.

Left: David Collette, technical director at Argotec, examines the film bubble on the company’s new blown film lab extrusion line.

Bobst, ei³ Support Customers

CHARLOTTE, NC—Bobst Group USA has formed a partnership with ei³ Corp., Montvale, NJ, to provide customers in the flexible materials business area with 24/7 real-time engineering support and productivity software.

A provider of real-time engineering and web-enabled data acquisition and reporting software, ei³ will enable Bobst customers to enhance the performance and uptime of their equipment with Tier 1 technical support. The service will focus primarily on larger-scale printing and converting processes for now.

Bobst Group and ei³ also offer a suite of productivity tools to Bobst customers, including monitoring, alarming, disaster recovery, recipe management, and downtime tracking.

Tech Center on the Way

NEWPORT, DE—Ciba Specialty Chemicals is building a customer-focused Technical Center near its Newport manufacturing facility. The facility will help Ciba test and verify the performance of Prime IT Surface Modification Technology. The technology causes the substrate to form an "invisible" nanolayer said to offer excellent adhesion performance.

Part 1 | Part 2