New Products

- Published: February 28, 2005, By PFFC staff

Machinery, Accessories, Services…

Enterprise Software has Many Features

Plastisoft Corp., Toronto, ON, Canada; 905/760-0100; plastisoft.com

Tori-Flex version 7 enterprise solution software for the flexible packaging and converting industries provides the ability to e-mail PDF forms for orders, quotes, invoices, purchase orders, and shipping documents via e-mail addresses automatically. Introduces wireless warehousing using hand-held Windows CE.net units from Symbol Technologies. Also provides more than 280 sales, production, and financial reports; improved credit check process; advanced RMA and returns of rolls, boxes, film and bags; and more.

Reposition Manual Slitters Quickly

Tidland Corp., Camas, WA; 800/425-1000; 360/834-2345; tidland.com

Linear rail mount for manual or semi-automatic slitters is designed to help converters reduce the time needed for repositioning company’s Performance Series knifeholders. Operators now can move manual knifeholders in seconds with no tools. Available on all new systems or as a retrofit.

Roll Splitter Low-Cost Alternative

Precision AirConvey, Newark, DE; 302/999-8000; precisionairconvey.com

The PAC Model 30 roll splitter removes defective and/or out-of-spec material from cardboard cores automatically. Slices through stretch film, foil, paper, and other materials in seconds without contact with cardboard core. Described as a lower-cost alternative to company’s larger Model 72 roll splitter.

Slitter/Rewinder has Station for Each Roll

Deacro Industries, Mississauga, ON, Canada; 905/564-6566; deacro.com

The MIR800A multiple individual rewind/slitter has a servo-driven shaftless rewind station for each rewinding roll. Winds as a standard in center-surface mode; optional pneumatic lay-on system allows operation as a center winder for increased sensitivity and the ability to wind a wide range of materials.

Slitter is economical

Dusenbery Worldwide, Randolph, NJ; 973/366-7500; dusenbery.com

Model 735DW cantilevered duplex center slitter/rewinder is available with razor and/or shear slitting. Said to be economical yet give same quality as higher priced model.

Recycle Large Portions

Erema North America, Ipswich, MA; 978/356-03771; erema.net

T-DD (double disk) technology is a new configuration of company’s recycling system designed to process feeds of larger-sized portions than previous models. New capability results in increased average production rates and reduced energy consumption, company says, and in many cases, it will eliminate the need for using a single-shaft shredder or other size-reducing equipment.

Roll Slitter has Options

ALS, Northamptonshire, England; +44 (0) 1933 225 755; als.ltd.uk

The 16-in.-dia S-Tec precision automatic roll slitter includes an automatic blade grinder with options for automatic pivoting blade angle and powered mandrel support. New model is designed to maximize yields and minimize waste. Available with mandrels of 1, 2, and 3 in. and widths from 63–84 in.

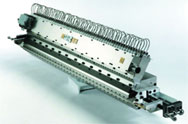

Slitter Gets "A" in Geometry

Titan, member of the Bobst Group, Bigglewsade, Bedfordshire, UK; +44 (0) 1767 310 100; bobstgroup.com

The CT610 automatic turret slitter/rewinder has a maximum running speed of 760 mpm (2,500 fpm). Linear tracking system gives perfect web geometry for handling a wide range of flexible materials. Can be supplied with automatic tape-down, core loading, and unloading of finished slit reels. Enables changeovers of less than 20 sec between sets.

Automatic Side Load Adjustment

Dienes Corp., Spencer, MA; 800/345-4038; dienescorp.com

"Genius"-level individual knife side-load force control via computer varies the amount of air pressure to the knife holder lower head assembly upon touchscreen command. Key is the patented Constant Side Load technology that removes stick-tion and hysteresis effects of the mechanical return spring in the lower knife head assembly.

Tape Slitter Aids Productivity

SCM, Rockaway, NJ; 973/983-7204; synerconslitters.com

The Model PSA-150 p-s tape slitter can be equipped with score and/or razor slitting to process most p-s film and paper tapes in slit widths down to 9 mm. Equipped with a dual-turret rewind, automatic rewind cutoff, and Dynamic Tabber for maximum productivity.

Slitter for Prepreg Material

Independent Machine Co., Fairfield, NJ; 973/882-0060; independentusa.com

A 72-in.-wide slitter with duplex rewind is for prepreg material with paper and/or film liners. Unit has zero backbend throughout the entire process to prevent delamination. Primary unwind has liner rewind and multiple paths for web inspection and vacuum splicing on either side of the web. Two secondary unwinds accommodate paper or film used as a leader or to relaminate liner to the prepreg through slitting process.

Knife Shaft Joins SR Series

Double E Co., West Bridgewater, MA; 508/588-8099; doubleeusa.com

Company has expanded its SR Series of products to include strip chucks, knife shafts, coreless shafts, and a core cutter shaft. Knife shaft is a tight-tolerance, external-element shaft that holds anvils or knives in place precisely for slitting operations. Knives can be placed anywhere along the body of the shaft. Once in position, a single air valve is used to supply air to the bladders.

Reduce Extrusion Costs

Windmoeller & Hoelscher, Lincoln, RI; 401/333-2770; whcorp.com

Filmex cast film line is available with web edge encapsulation system. A deckling system for the sheet die allows for encapsulation of the web edges, reportedly allowing production using inexpensive resins. After cutting, single-resin edge trims are fed back, in- or off-line, into the main extruder. An automatic neck-in recording features helps to further reduce the width of edge trims.

Slit Many Materials

Azco Corp., Fairfield, NJ; 973/439-1428; azcocorp.com

The Acu-Slit slitter is said to deliver clean, exact cuts to a wide array of rolled material, including paper, foil, film, plastic sheeting, and nonwovens. Designed as an add-on replacement unit for moderate-volume web processing lines, slitter is available in two formats, shear cut or crush cut, to accommodate applications from foil labels to breath strips to wallpaper borders.

Multilayers in One Pass

Schober USA, Cincinnati, OH; 513/489-7393; schoberusa.com

The MLPP-5 system for converting multilayered, self-adhesive products in a single pass features a central converting drum with five processing stations. Stations laminate, de-laminate, or die-cut materials such as films, foil, and p-s paper stock. Work-in-progress materials are said to stay in register throughout the production process.

Safety Chuck is Air-Operated

Goldenrod Corp., Beacon Falls, CT; 800/465-3763; goldrod.com

Safety chuck design features pneumatic open/close operation. Available in flange and foot-mount styles, core shaft support and torque transmission system can be operated with an air gun or fully automated by adding simple valving.

Baler Very Versatile

American Baler, Bellevue, OH; 419/483-5790; americanbaler.com

The 5029H baler comes in three cylinder sizes and six different power packs. Engineered to handle virtually all recyclable materials, including shredded or non-shredded secondary fibers, coated printers’ stock, corrugated (tri-wall and microflute) SBS, UBC, PET, and HDPE. Compression ratings are to 120 tons.

Safety Chuck brings Smooth Runs

Boschert, Mobile, AL; 800/479-0010; boschert.cc

The VT-7 safety chuck incorporates a square and round geometry. Round portion of the seat accepts the load of the roll, and the square portion accepts the torque. Design is said to provide a smoother, quieter run and cause less problems for quality control. Rolls can run at higher speeds with less vibration and wear to the seat of the safety chuck, company adds.

Measure Speed at Two Points

Beta LaserMike, Dayton, OH; 937/233-9935; betalasermike.com

Noncontact differential speed measurement system allows user to measure the difference in speed at two different points in the manufacturing line. Monitors product stretch or draw to ensure proper thickness and to prevent breaks. Also ensures two products being joined together during lamination are moving at proper speeds. Documents product quality by importing differential speed data into a statistical analysis package.

Affordable Process Control

Davis-Standard Corp., Pawcatuck, CT; 860/599-1010; davis-standard.com

MESA III process control system combines full process control with affordability, company says. Engineered for controlling smaller lines with one or two extruders, system’s processors can take advantage of features such as trending and recipe storage without costs for additional functions not required.

ERP Solution Aids Profitability

Tectura, Kennesaw, GA; 865/281-0990; tectura.com

ERP solution designated Packaging assists converters in capturing actual job costs and collecting real-time shop floor data, such as material waste for each job. Built on the Microsoft Axapta ERP platform, system allows converters to pinpoint areas in which they are inefficient and identify jobs that are costing them money.

Two New Coatings for Die Heads

Extrusion Dies Industries, Chippewa Falls, WI; 413/593-5742; extrusiondies.com

Ultracoat slot die coating heads are offered with Eversharp tungsten-carbide coated lip edges. Reportedly, edges can be made as sharp as stainless, are sharper than standard industrial chrome plating, and are more durable than either. Also available is chromium nitride-coated lips, said to exhibit outstanding consistency and accuracy.

Set Winder and Forget

Daven Industries, Fairfield, NJ; 800/834-8848; 973/808-8848; davenindustries.com

Portable winder allows nonelectric "set and forget" winding of any web in either direction. Winding speed follows the line of the material, while pneumatic drive system—with no gears or clutches—allows for stop-go or stalled motion. Micro-setting adjustments permit infinite speed and torque control, company says.

Vacuum Coater Suited for RFID

General, Bobst Group USA, Charlotte, NC; 704/587-2450; bobstgroup.com

The compact Holosec vacuum web coater is designed with technology for zinc sulphide, chromium, aluminum, and copper coatings. Also suited for developing coating solutions for RFID label applications and other flexible electronic circuit applications using low-cost PVD technology.

Set tension Accurately

Enercon Industries Corp., Menomonee Falls, WI; 262/255-6070; enerconind.com

Tension tuning device eliminates the guesswork in tension setting by predicting desired web tension scientifically. Company also offers a Plasma3 pilot line (pictured) for trialing atmospheric plasma and corona applications.

Brake Disc is Strong

Warner Electric, South Beloit, IL; 815/389-3771; warnerelectric.com

The ModEvo brake disc offers maximum strength with minimum weight, company reports. Design is optimized to make best use of the cooling air available at slow speeds. It is bi-directional, so achieves high heat dissipation capacity in either rotational direction.