Lasers Beam

- Published: September 30, 2004, By David Clark and Tony Hoult, Coherent Inc.

Digital converting is on the verge of widespread adoption in flexible packaging applications due to compact CO2 lasers.

The use of lasers in converting is expanding, particularly in the area of slitting/perfing paper products and scoring/perfing thin films such as polyethylene (PE) and polypropylene (PP) for applications such as flexible food packaging.

One reason for this increasing acceptance is the advent of small sealed lasers, which offer higher reliability and a low cost per watt.

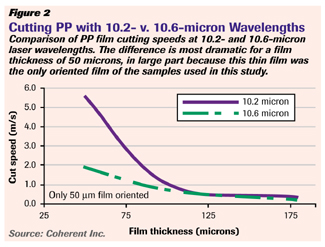

Also important has been the development of lasers with an output wavelength of 10.2 microns, which delivers up to a 3x increase in cutting speed for thin biaxially oriented polypropylene (BOPP) films.

This article reviews these advances and their impact in the context of two companies at the forefront of laser converting, LasX Industries and Alcan Packaging.

Smaller Lasers Simplify Integration

The advantages of noncontact laser processing over mechanical methods (e.g., rotary and platen dies) are well established. These include the ability to perform highly precise cutting, slitting, and perfing, and the absence of any tool costs or wear. In addition, the laser beam can be scanned at high speeds under digital (computer) control to provide flexible, programmable processing, i.e., infinite die shapes, intricate shapes, and instant order change — all at full production speeds.

The sealed carbon dioxide (CO2) laser is the most commonly used source for converting applications. These lasers deliver high-output power at low cost, as well as the high reliability needed for 24/7 processing, with typical service intervals in the 20,000-hr range. Moreover, their infrared (IR) output wavelengths in the 9-11-micron range can efficiently cut a wide range of materials including plastic films, multilayer (even metallized) films, paper, and cardboard.

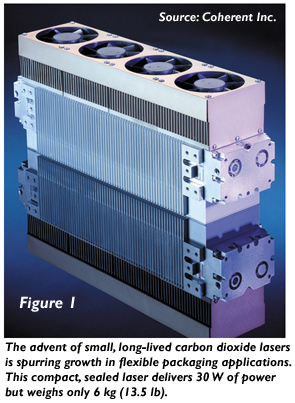

Sealed CO2 lasers also are compact, allowing them to be integrated directly into a slitter/rewinder, so their use adds no labor costs or additional processing. For example, a laser of less than 1.2 m (4 ft) in length and weighing only 36 kg (79 lb) can deliver up to 500 W of power. This is more than sufficient power for applications such as kiss-cutting labels, perfing multilayer carbonless paper, and through-cutting folding cartons.

Flexible packaging applications usually require much lower power levels in the range of 30-100 W. This is because of the relatively thin multilaminate film structures, less than 100 microns thick, commonly used in applications such as stand-up pouches for food packaging. In addition, typical laser processes used in flexible packaging — laser scoring for easy-open packages and laser perforation for breathable packages — require very little laser power.

To address these applications, a new generation of low-power, sealed CO2 lasers has been developed that offers the same high reliability, low cost per watt, and even smaller package size (around the size of a typical shoebox) — see Figure 1. These folded waveguide lasers are ideal for processing thin plastic (PP and polyester) films at speeds greater than 1,000 fpm. In addition to providing a cost-enabling solution for lower-power applications, the small size of these new lasers enables multiple lasers to be arrayed across a wide web (e.g., a 1.5-m/ 60-in.-wide master roll), delivering unprecedented process flexibility.

New Wavelengths Deliver Huge Advantages

Another important recent development is CO2 lasers with alternative output wavelengths to the standard wavelength of 10.6 microns. Laser wavelength is important because most thin polymer films in flexible packaging have wide variations in absorption of IR light; their absorption spectrum is characterized by fairly narrow peaks. Consequently, a small change in laser wavelength can result in a huge change in absorption. Specifically, by matching the laser wavelength to an absorption peak in the target film material, processing speed can be increased significantly.

The output of most CO2 lasers is centered at 10.6 microns. However, the use of wavelength-selective optics inside the laser can produce other wavelengths, such as 10.2 microns. Recently the impact of 10.2-micron lasers on thermoplastics was investigated under scientifically controlled conditions in an applications laboratory and summarized in a presentation at ANTEC 2004 (Annual Technical Conference/Society of Plastic Engineers, Chicago, IL)1.

In the case of unstretched PP films, there is only a small difference in processing speeds between 10.6 and 10.2 microns. But in the case of the commonly used BOPP, the difference was found to be quite dramatic (see Figure 2). This difference becomes much greater as the sample thickness is decreased, reaching a factor of 3x at a thickness of 50 microns and less. The investigations found the BOPP IR absorption spectrum shows a strong absorption peak near 10.2 microns, with no such peak at 10.6 microns. Moreover, this peak is present only in (oriented) stretched samples. (Consistent with this explanation, it also was found that the 10.2 laser cuts approximately 2x faster when the laser beam polarization is aligned with the film axis of maximum orientation.)

Laser output wavelength also can be changed by using different isotopes of carbon dioxide. For example, this approach can be used to create lasers with output centered at 9.4 microns. This wavelength produces optimum results when laser processing DuPont's Kapton (polyimide) films.

Ganging Multiple Lasers

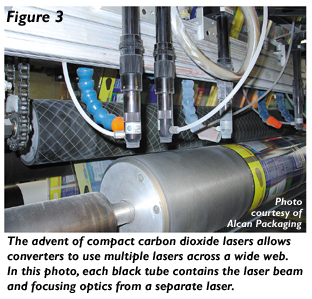

Alcan Packaging (formerly Pechiney Plastic Packaging), Chicago, IL, is a supplier of flexible packaging for the meat, dairy, and juice markets, as well as for health and beauty products. The company established patents and began laser scoring of film commercially in 1985. It now makes extensive use of laser converting with thermoplastic films and foils. Its laser-scoring technology has advanced to allow two-dimensional scoring of patterns into the web at repeating intervals. Alcan Packaging's senior process engineer, Finian Flood, explains, “The advent of compact, rugged CO2 lasers has enabled us to replace die boards and other mechanical tools for slitting, perfing, and scoring. Often we create smaller packages in a jumbo roll [up to 400 mm/15.75 in. in width]. For the wider rolls, we use up to 12 beams across the web, usually with fixed optics, for slitting and scoring along the web. We also have a line that uses optics to scan the beam across the web for complex shapes.”

Flood notes it is more practical to use multiple smaller lasers instead of splitting the beam from a single high-power laser (see Figure 3). The use of multiple lasers provides maximum flexibility since it allows real-time, independent control of each beam. He adds, “Scoring is increasingly popular for easy-opening food packages. Just a simple thing like small variations in film thickness could cause problems with mechanical scoring, but our laser processing can easily accommodate these variations. Also, the new generation of CO2 lasers can be tightly focused, thereby avoiding unsightly charring or kerf material along the slit or score.”

High-Speed Flex-Pack Converting

Since its inception in 1998, LasX Industries, White Bear Lake, MN, has grown to become one of the market leaders in laser converting. The company provides both its LaserSharp converting equipment as well as contract processing. Founder and president Bill Dinauer explains, “We created LasX to take advantage of the convergence of laser technology and market needs in high-speed digital converting. It seemed clear to us that US-based converting cannot stay indefinitely with mechanical tooling. Product cyles are now too short to justify tooling for on-shore converting operations. At the same time, the advent of compact CO2 lasers has enabled the implementation of ‘digital converting’ — computer-controlled laser converting. We believe that laser digital converting is now roughly at the same stage as sheet metal laser cutting in the early 1980s, i.e., on the cusp of widespread acceptance in production applications.”

Much of the LaserSharp equipment that is sold by LasX for flexible packaging applications is in the form of retrofits of existing slitter/rewinders. This cost-effective strategy integrates the existing functions of the slitter/rewinder with laser digital converting processes such as laser scoring and perforating, thereby providing multiple processes at no additional labor/time surcharge. Two retrofit configurations are available, one taking the form of fixed-beam downweb processing using multiple lasers, similar to the Alcan Packaging machines, and the other as dynamic (scanner-based) crossweb processing. Here the laser beam is rapidly scanned both across and along the roll to produce any pattern required. Depending on the web width, pattern complexity, and repeat pattern spacing, a typical scanner-based retrofit incorporates between two and four laser assemblies. LasX also has integrated its equipment into digital printers for digital converting of narrow webs (e.g., labels).

LasX is one of the first companies to implement 10.2-micron lasers for use on BOPP and laminated (PP/PE) polymer films. PP/PE is a common film structure used in food packaging where the PP outer layer provides for package strength and printing, and the inner PE layer provides a barrier to extend shelf life. Large increases in production speeds with 10.2-micron lasers allow smaller, less costly lasers to be specified, a factor in justifying the economics of laser digital converting.

The CO2 laser offers obvious advantages over traditional mechanical methods for many converting processes. Now that laser manufacturers are developing products that specifically target the needs of flexible packaging, this tool should see much more widespread adoption throughout the industry.

Tony Hoult has been with Coherent Inc. five years and currently holds the position of laser applications specialist. In this role he is responsible for developing novel laser processing applications. He holds a B.S. degree in materials engineering (Aston Univ., UK) and a Ph.D. in laser-based materials processing (Univ. of Warwick, UK). Contact him at tony.hoult@coherent.com; 408/764-4375.

David Clark has been a member of the Coherent team since 1997 and is currently director of marketing at the company. He is responsible for the materials processing market segment. David holds a B.S. degree in applied physics (Coventry Univ., UK). Contact him at david.clark@coherent.com. (coherent.com)

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).

1Hoult, T. and Dinauer, W. Improvements to laser processing of thin polymer films using non-standard novel laser wavelengths. SPE Conference, ANTEC 04.