Sleeve Labels | Technology Developments Drive Innovation and Sustainability

- Published: November 18, 2015

China represents no less than 32% of the global sleeve label market, reports AWA Alexander Watson Associates

A recent Sleeving Technology Seminar held in Brussels, Belgium, by AWA Alexander Watson Associates, provided an opportunity for all interested to update their knowledge. Expert speakers and a delegate base of industry participants benefited from a full day’s program of market and technology data.

A recent Sleeving Technology Seminar held in Brussels, Belgium, by AWA Alexander Watson Associates, provided an opportunity for all interested to update their knowledge. Expert speakers and a delegate base of industry participants benefited from a full day’s program of market and technology data.

Reviewing the market data

Seminar chairman Jos de Vries, consultant, AWA Alexander Watson Associates, opened proceedings by setting sleeve labeling in the context of the overarching global label market. He documented demand by region and label format, and he identified current trends and developments.

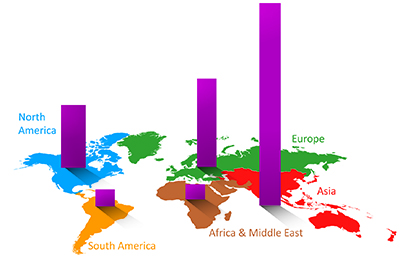

While pressure-sensitive labels show a return to growth levels higher than general market growth, he showed it is sleeve labels that continue to offer the greatest potential and the highest growth, at a global level, of 5%–5.5%.

Moving on to detail the profile of sleeve labeling, de Vries confirmed a surprising fact: Today, China represents no less than 32% of the global sleeve label market. It also claims a massive 50% of Asia’s regional demand.

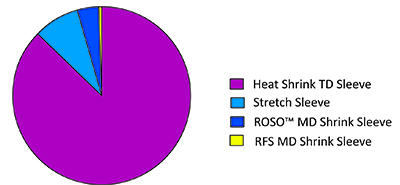

Heat-shrink transverse direction (TD) sleeves are universally the growth drivers, particularly, again, in China, but there are other technological solutions available. Roll-fed shrink films now can be sourced from a variety of suppliers, and now foam films that provide insulation, as well as tactile and graphic features, are gaining interest.

Solving the challenges of sleeve label design

Chris Stowe, product manager of Esko’s 3D and Design Solutions, addressed technology enhancements to the challenging task of designing sleeve labels, with their unique attributes and difficulties. Dave Kater, business manager, MDO–labeling for Klöckner Pentaplast Group, debated whether the MDO and TDO technologies are competitive, or complementary, and concluded that they walk hand in hand, depending on volumes, capital expenditure, and container design.

Substrates, handling, and conversion

Predicting the winding parameters of shrink sleeves is an important aspect of first-class production quality, as Quality Engineer Krzysztof Krystoziak from Masterpress showed. Dr. Matthias Henker, Flint Group Germany’s director of research and development, flexible packaging, EMEA, examined the opportunities for converting shrink sleeves with solvent-based inks.

Stretch sleeves were next on the agenda. Wölfgang Ploesch, business development director of CCL Label, presented examples of how technology and design have combined in the lightweight TripleS sleeve to deliver remarkable solutions today.

Sleeve labels and the environment

Of course, recyclability remains an issue in this aspect of the label market as elsewhere. Recoup CEO Stuart Foster, a director of EPRO (the European Assn. of Plastic Recycling and Recovery Organisations) updated delegates on current thinking.

The day-to-day activities of detection, removal, and sorting of film sleeves and plastic containers, without polymer cross-contamination, become increasingly complex as applications expand—but, by working in collaboration across the entire supply chain, plastic has the potential to be a truly sustainable, circular resource for the world.

Technology innovations

Michel Vanhems, business leader special effects, Sun Chemical, completed the individual presentations roster with an introduction to two breakthrough technology innovations: TouchCode – a new approach in consumer interaction that employs touch-screen-enabled device capabilities and printed electronics on inert materials; and deseamable shrink sleeves, which benefit from a coating in the seam area that permits their self-removal during the hot pre-wash step, prior to manual sorting.

The future?

The future of sleeving was the final subject on the agenda. It was considered in a cross-disciplinary panel discussion, interacting with the delegate base.

Wolfgang Ploesch, Matthias Henker, and Chris Frank of Klöckner Pentaplast—with moderator Jos de Vries—combined their knowledge and experience to come to agreement that it is technology that will drive sleeve labeling’s place in the product decoration market in terms of substrates, conversion, and application, and crucially, in terms of sustainability.

The seminar, sponsored by Klöckner Pentaplast, ended with post-event cocktails, at which participants expressed their satisfaction with a wide-ranging professional update.

AWA Alexander Watson Associates hosts a parallel event focused on the Asian market in Shanghai on December 1; and the major annual industry event, the AWA International Sleeve Label Conference and Exhibition 2016, will take place in Denver, CO, March 3–6 2016.