Proud & Proficient

- Published: April 30, 2004, By Stanley Sacharow, Contributing Editor

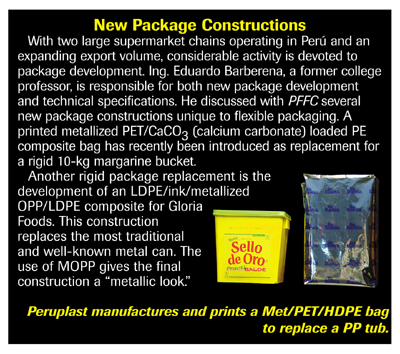

Peruplast takes pride in developing—then printing—metallized package constructions that stand out on a crowded shelf.

Business acumen coupled with superb technical proficiency have made Peruplast stand out dramatically among Latin America’s flex-pack converters. The leading converter in the Andean group and among the top six in South America, Peruplast ($30 million) began because of one man’s vision. In 1962, Hans Traver—German-born Fulbright scholar in journalism, American citizen, US Army veteran, and now a resident of Perú— co-founded a small converting operation in Lima, Perú’s capital city.

Traver, armed with an international business degree from Columbia Univ. and experienced in the then-emerging polyolefin technology, partnered with a Perúvian resident to introduce flexible packaging into the country. Prior to the 1960s, most flexible materials used domestically were imported.

Tech Pak SA ($18 million), Peruplast’s sister operation, is located about six miles away from Peruplast. A dedicated flexo converting plant, Tech Pak was covered extensively in PFFC’s April 2003 issue (Guts & Glory). This month’s article is based on an exclusive PFFC visit to both Peruplast and Tech Pak.

Four Operating Units

Located in the “El Pino” industrial area of Lima, Peruplast is spread over 230,000 sq ft and employs 410 people. In 1996, Chile-based Alusa SA purchased a 25% share in both Peruplast and Tech Pak. By far the largest and most vibrant flex-pack converter in Perú, the company is divided into four distinct operating units. These are the converting plant, a high-density (HD) polyethylene (PE) film bag division, the fractional melt index (M.I.) PE division (fertilizer bags), and the PE shrink film extrusion division.

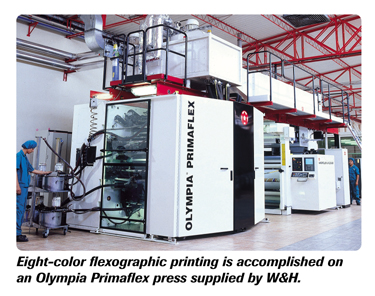

The converting operation contains two eight-color Grafomac rotogravure presses and one eight-color flexographic press from Windmoeller and Hoelscher (W&H). There are three lines of triple coextrusion supplied by Battenfeld Gloucester, Kiefel Extrusion, and Macchi. One Battenfeld two-layer coex line completes the coextrusion capability of the converting unit.

Lamination is accomplished by two solventless Nordmeccanicas and one solvent laminator from Polytype. There appears to be a distinct effort to keep all the foil lamination equipment up to date. While touring the facility, Traver told me “obsolescence is not so much a technical problem as it is a question of the order mix. Your 12-year-old press is quite cost efficient with runs of two million feet, but what do you do when you have four or more job changes in 24 hours?”

Production Unit II is the facility for the manufacture of HD–high molecular weight (HMW) PE film/bags. This technology was introduced to Perú by Peruplast. There are seven HMW extruders, supplied by Kiefel and Carnevalli, with a monthly capacity of 380 metric tons. Production is converted into both film and bags. Printing is accomplished by two wide flexographic presses from Uteco and Comexi.

For the final conversion into bags, there are 12 Poliblock bagmakers from Polimáquinas. Production of Unit II averages five million bags daily.

Production Unit III is dedicated to the extrusion of fractional M.I. PE. The 450-metric-ton capacity is used to extrude film in 7–8 mils for 50-kg fertilizer bags and 1.5–10-mil bags in general. This unit also recycles low-density (LD) PE on two separate lines. There are seven extrusion lines provided by W&H, Kiefel, and Brampton Engineering. The printing is flexographic (also W&H) and six heavy-duty bagmakers are in operation.

Production Unit IV is the facility where PE shrink film is produced. Much of the shrink film is dedicated to the bundling of soft drink bottles and is somewhat of a seasonal operation. Four extrusion lines—supplied by Carnevalli, Brampton, and Rulli Standard—have a capacity of 400 metric tons monthly. The finished rolls normally are 1,500 m in length and as many as six rolls per line are taken off. Fractional M.I. resin (PE) is used for the shrink film.

The Sister Plant

Tech Pak SA ($18 million) is a separate plant that began operations in 1986 when Traver purchased the Van Leer facility in Lima. There are 269 employees working at Tech Pak’s 170,000-sq-ft facility. There are seven flexographic presses; four are from Paper Converting Machine Co. (PCMC), one is from Uteco, and two are from Flexotecnica. Five of these presses are eight colors with widths to 52 in.; the Flexotecnicas are six colors and 52 in. The latest press is the PCMC eight-color Avanti assembled in Brazil, which was installed in late 2002. Production capacity of the fifth unit—the Tech Pak converting plant—exceeds 20 million lineal meters per month of quality print.

Tech Pak operates three solventless laminators (Nordmeccanica, Uteco, and Comexi) with a capacity of 300 metric tons monthly. There are nine bagmakers and three Narita label machines. Fifteen slitter/rewinders—many from Bimec—complete the conversion process.

Five extrusion lines (from Battenfeld, Carnevalli, Kiefel, and Ciola) constitute Production Unit VI and provide both the LDPE and polypropylene (PP) films used in Tech Pak’s converting plant.

Prepress is accomplished with fully state-of-the-art equipment from suppliers such as Barco (now Esko-Graphics), Creo, and GretagMacbeth. More than $2 million has been invested to provide fully operational computerized prepress for the flexo and gravure requirements in both plants. Peruplast and Tech Pak together operate 28 extrusion lines with screw diameters from 30–120 mm. Total extrusion capacity is around 20,000 metric tons annually.

Mirtha Guevara, once an exchange student in New Mexico, heads up the administrative unit dedicated to both import/export and purchasing. She notes that “all our suppliers are selected based on their reliability, and their products must be approved by our technical department. escortnavi geneva We project the imports of most of our raw materials five months into the future.”

Raw material and substrate suppliers include Alcan Aluminio, Biofilm S.A., Equistar Chemicals, Henkel Corp.,Mitsubishi Polyester Film, Sidopack S.A., Sinclair S.A., Dow Chemical Co., and Vifan Canada.

Fernando Del Carpio, Peruplast’s general manager, also explains that “our customers range from the large multinationals such as Kraft, Nestlé, Unilever, and Procter & Gamble to local customers such as Gloria, Santa Isabel, Alicorp, and Intradevco.” He adds that “in 2003, we exported over $8 million to South America, including Caribbean countries—even to Puerto Rico.”

Peruplast and Tech Pak reflect the very best of Peruvian industry: ISO 9001-2000 certified, “exemplary” American Inst. of Baking approval, and member of the Flexible Packaging Association. The companies boast a savings and medical program coupled with a fully subsidized work cafeteria. Employee stability added to investments in state-of-the-art manufacturing equipment are the two ingredients necessary for continued growth. Add to these factors a growing export market and you have all the earmarks of a winner!

Supplier Info

Grafomac Casale Monferrato, Italy; +39 0142 75972

Windmoeller and Hoelscher whcorp.com

Battenfeld Gloucester bge.battenfeld.com

Kiefel Extrusion GmbH kiefel-extrusion.com

Macchi S.p.A. macchi.it

Nordmeccanica nordmeccanica.com

Polytype Converting polytpe.com

A. Carnevalli & Cia. carnevalli.com

Uteco Converting uteco.com

Comexi SA comexi.com

Polimáquinas Indústria e Comércio Ltda. polimaquinas.com.br; poliblock.com.br

Brampton Engineering be-ca.com

Rulli Standard rullistandard.com.br

Paper Converting Machine Co. pcmc.com

Flexotecnica/Cerutti Group flexotecnica.it

Narita Indústria e Comércio Ltda. narita.com.br

Bimec Srl bimec.it

Ciola/Acmack Indústria e Comércio de Máquinas ciola.com.br

Esko-Graphics esko-graphics.com

Creo creo.com

GretagMacBeth gretagmacbeth.com

Alcan Aluminio Do Brasil alcan.com.br

Biofilm S.A. biofilm.com.co

Equistar Chemicals LP equistar.com

Henkel Corp. henkelcorp.com

Mitsubishi Polyester Film m-petfilm.com

Sidopack S.A. sigdopack.com

Sinclair S.A. sinclair.com.co

Dow Chemical Co. dow.com

Vifan Canada vifan.com

Stanley Sacharow has been in the flexible packaging industry for more than 35 years. His company, The Packaging Group, is an organizer of targeted conferences and a consultant to the international packaging/converting industry. He is also the author of PFFC’s “Package Converting” column. Contact him at 732/636-0885; univpac@aol.com.