Bio Break Down

- Published: March 31, 2004, By Robert Boyle, Cortec Corp.

Technological breakthroughs in biodegradable flex-pack products have created a very real competition with their non-biodegradable counterparts.

With the renewed interest in biodegradable flexible packaging products has come widespread confusion over what is “best” and what is truly “biodegradable.”

Once these products are broken down and understood, it is obvious there is not one “best” product but many. More to the point, it is more important to evaluate a product based on its intended purpose than it is to debate the technical aspects of each.

Technical and chemical properties certainly are used in the evaluation of biodegradable products; however they should not be the only factors in selecting a product for your customers. One important factor is how the different technical aspects of each category of products affect the usability and performance of the finished product as determined by the end-consumer. After all, how well a product performs its intended purpose is what will determine its long-term viability in the marketplace.

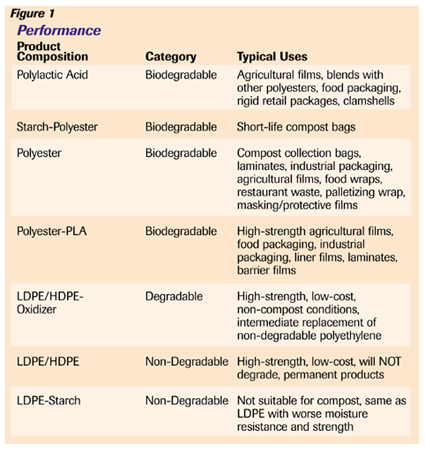

In order to evaluate products based on these criteria, it is necessary to understand how products biodegrade or degrade. Most of the technologies fit into one of three categories (described below). For simplicity, organic waste collection bags and films will be used to exemplify the differences between technologies, as these bags are not readily removed from the waste stream (see Figure 1). Packaging products that are readily recyclable are not key markets for biodegradable or degradable technologies, as they don't have a disposal phase in their life cycle.

Product Categories

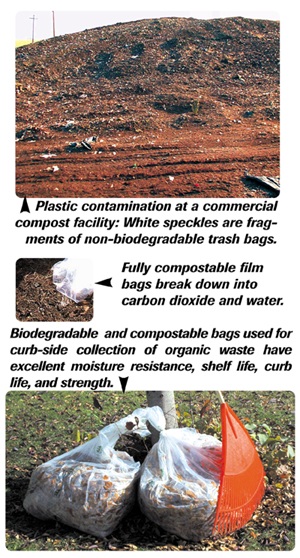

Biodegradable Products — A product is considered biodegradable by most international and domestic standards if, under certain “realistic” conditions, it turns into basic materials. For the purposes of biodegradable bags, for example, the realistic conditions are based on temperature, humidity, microorganisms, and others. The basic materials are carbon dioxide and water. Thus, a biodegradable material is suitable for compost if, under commercial compost conditions, it breaks down into carbon dioxide and water.

Degradable Products — A product is considered degradable by most standards if, given a trigger, the product breaks down into basic elements. The difference between “degradable” and “biodegradable” is widely debated as the end result is most often the same — carbon dioxide and water are released. With some degradable products, the only reason they cannot meet biodegradability standards is the time constraint on the process of converting the polymer into carbon dioxide and water.

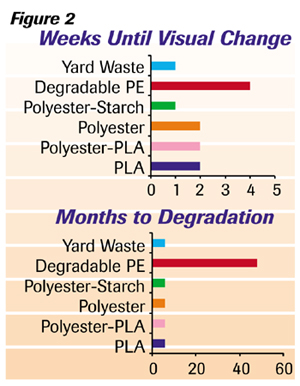

There are two primary differences between “degradable” and “biodegradable.” First, high heat, moisture, or UV exposure most often causes the degradation of a degradable product, whereas microorganisms degrade a biodegradable product. Second, degradable products tend to take longer to turn into carbon dioxide and water (see Figure 2). Since the compost purchaser cannot distinguish between film that eventually will degrade and non-degradable film, any film remnants (partially degraded or not) will devalue the finished product.

Non-Degradable Products — Intuitively, a non-degradable product does not break down into basic elements. A product that breaks apart, but remains chemically the same, is non-degradable. For example, you can put small amounts of starch into a polyethylene (PE) trash bag. The end result is a trash bag that breaks apart when placed in contact with moisture. However, the PE will remain intact. You have the same end result as cutting the trash bag into small sections with scissors.

Uses for Biodegradable Products

A flexible packaging product that is considered biodegradable can be categorized further based on its composition. The two most common categories of biodegradable packaging technologies are polyesters and blends.

A blended biodegradable packaging product typically is polyester mixed with starch. Starch is highly marketable as it is considered bio-based (even if used in minimal amounts) and is relatively inexpensive. A majority of biodegradable/compostable bags use this technology. Starch-polyester blends typically excel when rapid disintegration is desired. A compost operator that wants visual change in a couple of days will be impressed with these products.

When blended bags are evaluated in terms of performing their intended function, the weaknesses sometimes outweigh the benefits. When exposed to moisture, bags containing starch will tend to break apart. For example, filling a starch-polyester bag with wet leaves and placing curbside can result in the bottom falling out when a hauler picks it up. Also, shelf life, curb life, and useful life tend to be limited in comparison to non-blended formulations. If compost programs include restaurant waste or even hot, moist coffee grounds, blended products can have poor results. Blended products also would include limestone-starch blends, blends used for cutlery, and rigid packaging cartons [polylactic acid (PLA) blends]; however these are not flexible packaging products and therefore have not been included in this categorization.

PLA is a form of polyester that is the result of fermenting cornstarch through a complex process. The end result is a very versatile material with a low moisture vapor transmission rate (MVTR), high clarity, and impressive strength. It is important to note PLA is different than the starch used in the blends described above. When used at high concentrations, PLA is a very rigid material ideal for cups, clamshell packages, molded containers, and laptop computers. However, its rigidity makes it a poor material for compost collection bags.

Again, polyesters are very versatile. Polyester bags for compost collection have excellent moisture resistance, shelf life, curb life, and strength. In fact, they are stronger than standard PE bags. Polyester bags ideally are suited for collection of wet organic waste, including restaurant waste and wet yard waste. When combined with low concentrations of PLA, polyester bags also can be used in high-strength areas such as agricultural films and industrial and protective packaging.

Uses for Degradable Packaging Products

Degradable packaging products are most often the result of blending a substance into PE. The substance attacks the PE causing degradation once certain environmental conditions exist — temperature, UV exposure, and others. These products look, act, and perform just like their non-degradable counterparts, except they break down after being discarded.

Degradable packaging products can replace nearly every plastic used today and even can degrade gradually in some landfill conditions. They bridge the gap between non-biodegradable and the typically more expensive biodegradable products since widely used low-density PE or high-density PE is the main component.

For compost collection bags, however, the degradation may not be triggered at all or may take too long once it is triggered. There is a debate as to whether typical compost conditions will trigger the oxidation mechanism that reduces the PE's molecular weight, making it consumable by microorganisms. Even if it is triggered, degradable PE typically will not meet the time constraints placed on it by international and domestic standards. There is even more debate as to whether this time constraint is a valid one.

A degradable PE bag entering a commercial compost site likely will remain in the finished compost for up to four years. For most site operators, this is simply too long. Any evidence of plastic contamination (partially degraded or not) lowers the potential sale price of the compost. For areas where large amounts of PE are discarded outdoors or in waterways, degradable PE could be the most cost-effective way of reducing the problem until cost-effective, fully biodegradable products are used more widely.

Selecting a Suitable Product

Many converters and consumers have been bombarded with product information on the “latest and greatest” biodegradable plastic materials. Compound this with the debate over certification standards and the public is left bewildered, confused, and perhaps even distrustful. When examining a biodegradable product, try placing it in one of the three general categories discussed here. Then ask yourself two simple questions: How will this product perform its intended function? What will happen to this product once discarded using the intended method?

If the bags are being used for collecting organic waste that will be sent to a commercial compost site, the bag should be strong enough to endure the rough handling and weather yet biodegrade by the time compost is ready for sale. A starch-polyester bag will biodegrade in time but may not last long enough while sitting on the curbside. A degradable PE bag will last long enough on the curbside, but may not degrade by the time compost is ready for sale. A polyester bag will contain the wet organic material on the curbside, even during rainy weather, and will biodegrade at the same rate as its contents once at the processing facility.

Alternatively, a customer that wants a tough agricultural film for weed control and moisture retention has a few more options. The starch-polyester film will not retain soil moisture or control weeds for much longer than a week. A degradable PE film will have sufficient strength and moisture resistance and eventually will degrade — a better option than leaving non-degradable plastic floating around a field. Similarly, a PLA-polyester blend will provide moisture retention and weed control but will be stronger and can be composted or tilled-under to accelerate the biodegradation.

Once the products are categorized, it is much easier to evaluate how well they will fulfill your customers' needs.

Robert Boyle is technical product manager for biodegradable packaging products at Cortec Corp., St. Paul, MN; ecofilm.com. Cortec has engineered numerous biodegradable packaging products including polyesters, PLA, and degradable PE as well as industrial, corrosion-inhibiting, and static dissipative versions. Contact the author at bboyle@cortecvci.com

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).