Disposable DVD Requires More Than an 'Ordinary' Package Deal

- Published: April 05, 2004, By Edited by Teresa Koltzenburg, Senior Editor

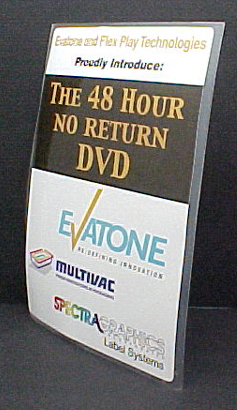

Evatone is leveraging a customized Multivac machine and oxygen-scavenging film from Cryovac to produce packaging for “time-sensitive” movies.

Open the package; insert DVD into player; enjoy movie for 48 hours; self-destruct.

This scenario is what Evatone was looking to deliver in each low-cost, convenient DVD the Clearwater, FL-based company was contracted to produce. With just two days of DVD viewing available, the packaging selected had to be exact enough to preserve the integrity of the product's time-sensitive technology - without question.

Explains Evatone's VP of manufacturing Doug Franzen, “With the special DVD technology we replicate for Flexplay, we need to ensure the packaging has a guaranteed seal and shelf life of at least one year from the date of purchase. Multivac's unique thermoform, fill, and seal vacuum-packaging technology provided us a with comfort level that allowed us to break into the limited-play technology market with a bang, keeping consumers coming back for more.”

According to Evatone, staying ahead of market trends and helping clients reach business objectives have been the driving forces behind the family-owned business. During its 78 years in operation, the company has been no stranger to print, audio, data, and other multimedia products. And when an opportunity to manufacture, market, and distribute the latest technology - like the disposable DVD - presented itself from its long-standing client Flexplay, Evatone went to work.

A Sound Solution

Evatone solicited the help of Multivac Inc. to develop a vacuum-packaging solution - that also incorporates Cryovac's OS (oxygen-scavenging) film - that would maintain the technology's reliability each time a consumer purchased a date-triggered DVD for viewing. The resulting package enabled the company to break into a new information medium that brings entertainment to movie buffs without concern for video-store late fees or storage issues.

“We've been working with Flexplay Technologies for more than two years to develop a barrier package that prevents the rust-like oxidation reaction in the EZ-D from occurring during handling and distribution,” explains Tom Kennedy, new business development manager for Cryovac's OS systems. “Our proprietary oxygen-scavenging systems provide the perfect solution to remove residual oxygen quickly, ultimately achieving less than one-tenth of one percent - or mere 'parts per million' levels - of oxygen within the package in just a few days.”

Time-Sensitive Packaging

Having a design and the Cryovac film technology already in mind, in November 2002, Evatone began consulting with Multivac's packaging experts, who helped streamline the machine design to ensure the time-sensitive DVD concept worked. The final result of the collaborators' effort was a thin 5 x 7-in. package, comprised of Cryovac OS flexible film, covered with a heavy-duty card label.

Today, Evatone is producing these packages on a customized R530 thermoform, fill, and, seal rollstock packaging system supplied by Multivac Inc. According to Evatone, the R530 incorporates in-line printing capabilities, equipped with three label printheads. This type of package also can be produced on a similar version of the machine, the R240, adds Evatone.

“Not only was Multivac's impressive engineering team cooperative,” says Franzen, “we also liked the company's expertise and solutions. Even during our initial discussions, we gained an understanding quickly of how Multivac's after-sales service and support would help us maintain productivity levels without interruption,” he adds.

The Multivac R530 enables Eva-Tone to schedule flexible production runs, ranging from production of a few thousand per day to hundreds of thousands a day. States Franzen, “By bringing the business benefits of quick changeover and the capability to program small or large cycle loads, we felt Multivac's solution offered the best product for versatility. The rollstock's flexibility allows for the use of a single label head, or utilization of all three, to fit our changing production, as well as overall market, needs,” Franzen adds.

Seizing the Market

As multimedia technology continues to change at a mind-boggling pace, companies like Evatone have had to learn to grab hold of the opportunities instantly yet sustain profitability. Critical to success - both in return on investment and product quality - is creating packaging that enhances a product's usability and integrity. Notes Flexplay CEO Alan Blaustein, "Bringing this new technology to market with the certainty the packaging would maintain the disposable DVD's integrity specifications was a critical component for us to be successful [in this particular venture].”

With the advanced vacuum-seal technology provided by Multivac's equipment and the oxygen-scavenging capability of Cryovac's film, Evatone was able to deliver the certainty Flexplay desired. “The package design and production process enables us to package the DVD right after manufacturing, subsequently protecting the valuable, time-sensitive technology pressed into it,” reports Franzen. “This disposable DVD opportunity prompted Evatone to implement a cost-effective packaging solution that is able to protect critical data and that can be disposed of easily after use without hindering the environment.”

Evatone

4801 Ulmerton Rd.

Clearwater, FL 33762, USA

eva-tone.com

Supplier Info

Multivac Inc., Kansas City, MO, USA; multivac.com

Cryovac, a div. of Sealed Air Corp., Duncan, SC, USA; cryovac.com