Sustainability Beyond Recyclability

- Published: July 05, 2022

By Nathan Klettlinger, Global Marketing Director for ProAmpac

More brand owners are setting sustainability targets and greener legislative initiatives are on the rise making more sustainable flexible packaging a core decision for many brands and retailers. By adding sustainability to the essential packaging requirements of cost, machineability of material, barrier requirements and shelf appeal, converters are navigating an increasingly complex environment.

More brand owners are setting sustainability targets and greener legislative initiatives are on the rise making more sustainable flexible packaging a core decision for many brands and retailers. By adding sustainability to the essential packaging requirements of cost, machineability of material, barrier requirements and shelf appeal, converters are navigating an increasingly complex environment.

Even though recyclable films are an option in some applications, it is not a universal fit. For example, traditional cosmetic web (PET/PE/foil/PE) and paper/poly/foil/poly structures offer good stiffness, barrier and filing on high-speed machines, but are challenging to make recyclable. Also, high residue products or products that require a barrier such as foil to meet shelf-life requirements are not currently eligible for recyclability through existing streams. Fortunately, there are other options to suit end-product requirements while supporting customers’ sustainability goals.

Post-Consumer Recycled Content

One of the simplest ways to increase sustainability of a package is by including post-consumer recycled content (PCR). There are two primary types of PCR: mechanical recycled PCR and chemical recycled PCR. Mechanical PCR is the most readily available and can be used at various percentages in film layers.

During the mechanical recycling process, polymers are reduced in size via grinding, then they are melted, pelletized and mixed with virgin resins during extrusion. Both PET-PCR from water and soda bottles, as well as PCR-PE from milk jugs are available for films. PCR-PET can be added at relatively high levels to film and performance and appearance is nearly unaffected. PCR-PE can also be added at varying levels but may be more noticeable in films at higher levels due to the presence of small gels in the product.

Resins recycled via chemical or advanced recycling offer properties far superior to mechanically recycled resins. During the chemical recycling process, polymers are broken down chemically into simpler molecules. Though more limited in availability, investment in chemical recycling is growing. Chemically recycled resins are ideal for applications where the packaging use is sensitive to the appearance of gels or inclusions, or where strength cannot be compromised.

Renewable Materials

Another option for sustainable packaging is that made of bio-based renewable materials. Paper is the most widely recognized renewable material, but bio-based polymers are also available. By incorporating a renewable material, packaging users can reduce fossil-fuel-based plastics while often reducing their carbon footprint. The reduced reliance on virgin polymers helps support sustainability goals without sacrificing product protection. If a customer does pursue a renewable resin alternative, a Life Cycle Assessment should be performed to quantify the carbon reduction.

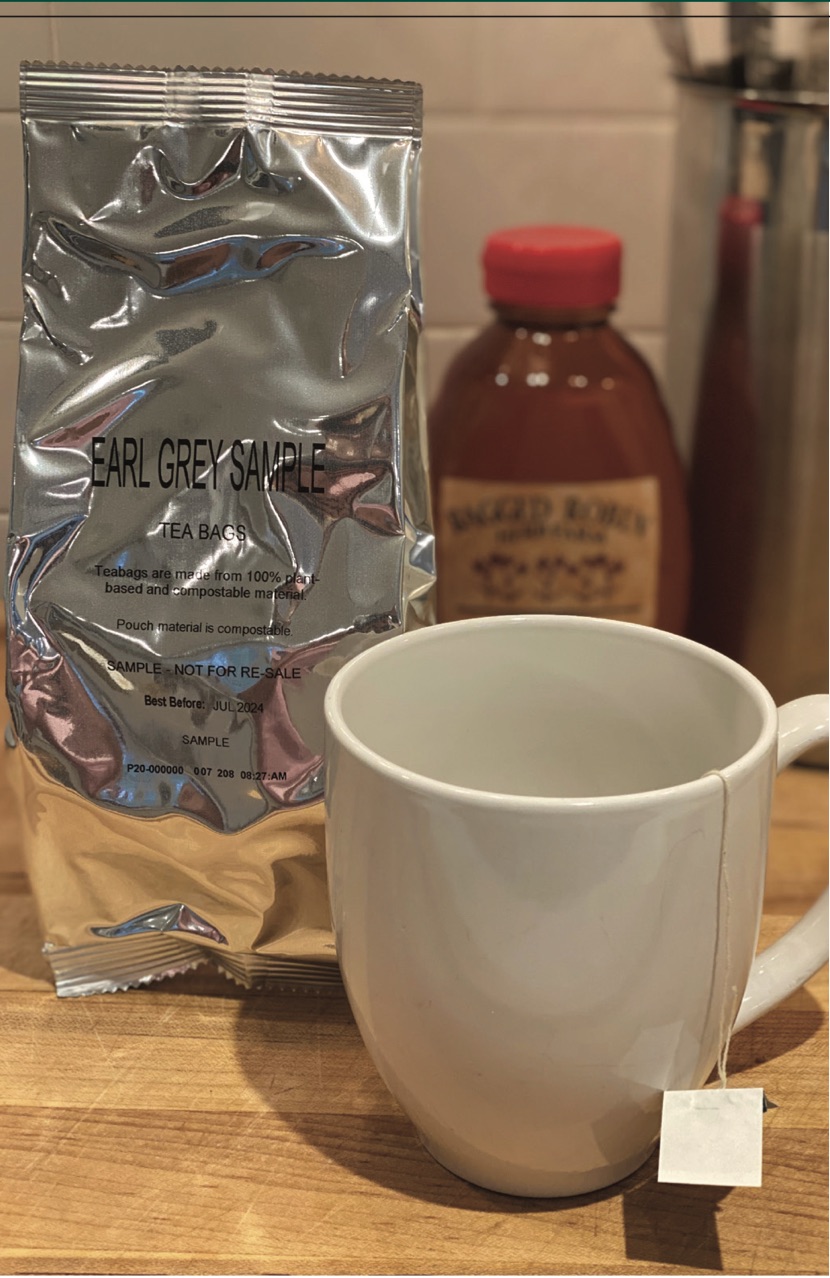

Compostable Materials

Compostable Materials

Compostable materials are a well-known alternative to conventional films where the end-product would render recyclability unavailable. Available in both paper-based and film-based versions, compostable materials are ideally suited for high-speed machines that require stiffness or which have high residue like food waste that would render the product non-recyclable. Compostable structures can be designed with standard and high barriers and can either be designed to compost in industrial composting facilities (136oF) or in home composting bins. Since industrial composting facilities and home compost are suited to hold the organic residue left with some end-products, this material is an ideal alternative for food and lawn care brands with specific sustainability goals. Also, compostable packaging can be ideal for high-speed machines which require stiffness to ensure performance on high-speed filling machines.

In all, material science continues to innovate sustainable alternatives to conventional laminated films to ensure end-products that are ineligible for recyclability can still be packaged to help customers achieve their goals. With the emergence of new technologies, packaging is becoming more sustainable without sacrificing product protection. However, the key to optimal sustainability initiatives is to ensure the packaging material selected suits the end-product to ensure that the two are compatible for the ideal end-of-life disposal scenario.

About the Author

Nathan Klettlinger leads the ProAmpac strategic marketing team whose goal is to promote profitable growth and align company objectives with customer needs. Nathan held roles in product development, product management and market segment management. He has a Bachelor of Science in Chemical Engineering and an MBA from the University of Akron.