Converting to Printed/Flexible Electronics

- Published: April 03, 2023

By Dr. Matthew Dyson, Principal Technology Analyst, IDTechEx

Asked to picture an “electronic circuit,” what comes to mind? Likely a rigid green rectangle with some resistors, capacitors, etc. soldered on top. While conventional printed circuit boards (PCBs) like this dominate the market today, there is an alternative approach that utilizes equipment and expertise from the graphics printing industry: printed/flexible electronics.

By replacing rigid with flexible substrates and etched copper with printed conductive traces, printed/flexible electronics offer a distinct value proposition. Circuits can be lighter, produced more cheaply (using digital and/or continuous manufacturing methods), cover large areas, are more sustainable since manufacturing is additive not subtractive, and flexible or even stretchable. As such, printed/flexible electronics enable new applications where conventional electronics are either too costly or where the form factor of conventional rigid PCBs is inappropriate.

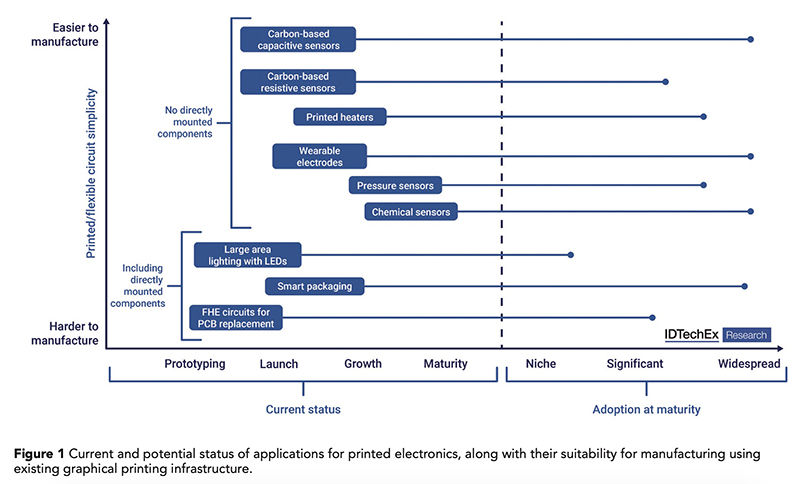

Promising Applications

While printed/flexible electronics is often introduced as an “emerging technology,” it has actually been used for years in some common applications. Seat occupancy sensors in vehicles are a great example, since the pressure sensors need to cover a relatively large area and deform to ensure the seat stays comfortable. Glucose test strips used by diabetics are another large and established market for printed electronics, with billions of strips sold every year.

Existing applications only represent a small proportion of the potential market for printed/flexible electronics. Arguably the biggest growth driver is increasing digitization and the associated demand for data from an ever-wider range of sources — sometimes referred to as the “internet of everything.” Printed/flexible electronics enable low-cost, flexible sensors to be attached to almost any object you can think of, enabling real time monitoring of almost anything you can think of, from the human body to buildings.

Healthcare/wellness is an especially promising sector for printed/flexible electronics, since the flexibility and even stretchability makes wearable sensors such as electronics skin patches much more comfortable. Some applications, such as pressure-sensitive insoles that can analyze gait in real time, are already available, while replacing bulky wired sensors worn in hospitals with conformal wireless counterparts is an active development area.

Manufacturing Methods

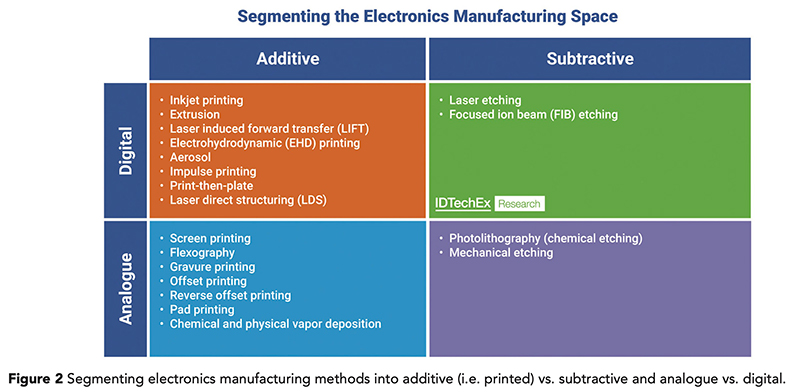

Given the wide range of length scales and throughputs required, an almost bewildering array of printing methods can be used to produce printed electronics. Analogue methods, which repeatedly impart an initial design and are suitable for high volume production, are broadly similar to those used in conventional graphics printing: screen printing, flexography, gravure, offset-lithography, pad printing. This commonality provides a great opportunity for companies with the relevant expertise and equipment to branch into the emerging printed/flexible electronics industry.

There are also multiple digital printing methods that enable direct control of the printed pattern. While inkjet printing is well-known, other emerging methods such as aerosol printing, laser-induced forward transfer, electrohydrodynamic printing and impulse printing are targeted primarily at printed electronics. These methods typically bring a distinct benefit, such as the ability to apply ink without contact to 3D surfaces, handle a very wide range of viscosities or print extremely narrow (1um) traces.

Screen printing is by far the most widely used of all the printing methods. Unlike most other approaches, it is compatible with high viscosity conductive inks, which enables sufficiently thick traces for the desired conductivity to be deposited in a single pass. Furthermore, the same technique can be used economically across a range of production volumes, with flat-bed screen printing for small batches and rotary screen printing for high volumes.

Of course, an electrical circuit is more than just the conductive traces. Some functional components, such as sensors, batteries or even photovoltaic panels can be printed directly onto the same substrate, but integrated circuits (ICs) that provide data processing capability typically need to be produced separately. This requirement can be resolved with two competing approaches: flexible hybrid electronics (FHE) which utilizes pick-and-place technology from the electronics industry to mount components onto flexible substrates, and connecting a fully printed circuit to a conventional PCB. For companies looking to leverage printing expertise into the electronics space, partnering with a contract PCB producer to employ the second approach is likely to be more straightforward.

In-line Quality Control

While quality control is of course important for graphics printing and converting, the demands for printed/flexible electronics are more stringent. Rather than just an aesthetic blemish, an issue with print quality could cause the entire device to fail, making any mounted components or other comparatively expensive parts such as batteries redundant. In-line quality control is especially important with continuous manufacturing, since an undiagnosed problem could lead to large volumes of material, including expensive conductive ink, being wasted.

To address this challenge, various quality control methods are utilized or proposed. Machine vision is arguably the most straight-forward, with video of printed conductive traces automatically checked for cracks or defects. If the circuit is stationary, perhaps only temporarily, electrical connectivity can be tested with flying probes that are controlled from above to contact specific locations. A particularly innovative quality control method is applying spectroscopy to determine conductivity without electrical contact. Similar to CMYK calibration bars used to check conventional print quality, a “test pattern” is printed and the reflected radiation analyzed.

Leveraging Existing Capabilities

Printed/flexible electronics provides a great opportunity for printing companies to leverage their existing capability to produce new, often higher-value products. Indeed, some companies with a background in graphical screen printing are employing this strategy, with sensors a common application.

Arguably the best approach, at least initially, is to focus on producing circuits where all the functionality can be printed, rather than introducing the complexity of integrating pick-and-place of electrical components. For companies with high volume roll-to-roll capabilities, focusing on the simplest applications (such as moisture or touch sensors) or those where large areas are required will likely be the most promising,

About the Author

Dr. Matthew Dyson is Principal Technology Analyst at IDTechEx (www.IDTechEx.com), which supplies market research and intelligence via reports, subscription and consulting services covering a wide range of emerging technologies. Matthew focuses on printed/flexible/3D electronics and how these manufacturing and material innovations facilitate disruptive technologies such as electronic skin patches, smart packaging, digital manufacturing and smart surfaces.