Driving Flexibility and Cost Savings With Modular Cutting Assemblies Exploring Alternatives to Inflexible Purpose-built Production Equipment

- Published: July 22, 2024

By Andrew Zucaro, Founder and President, AZCO Corp.

Traditionally, cutting operations on converting lines are tightly coupled with a single large-scale manufacturing process - an approach that involves costly, purpose-built machines designed for fast line speeds, around-the-clock operation and high-volume web speeds. Despite their benefits, however, these monolithic machines don't serve every application. Low- and medium-volume converting operations, as well as production lines requiring frequent changeovers, would benefit from a more flexible manufacturing approach.

Traditionally, cutting operations on converting lines are tightly coupled with a single large-scale manufacturing process - an approach that involves costly, purpose-built machines designed for fast line speeds, around-the-clock operation and high-volume web speeds. Despite their benefits, however, these monolithic machines don't serve every application. Low- and medium-volume converting operations, as well as production lines requiring frequent changeovers, would benefit from a more flexible manufacturing approach.

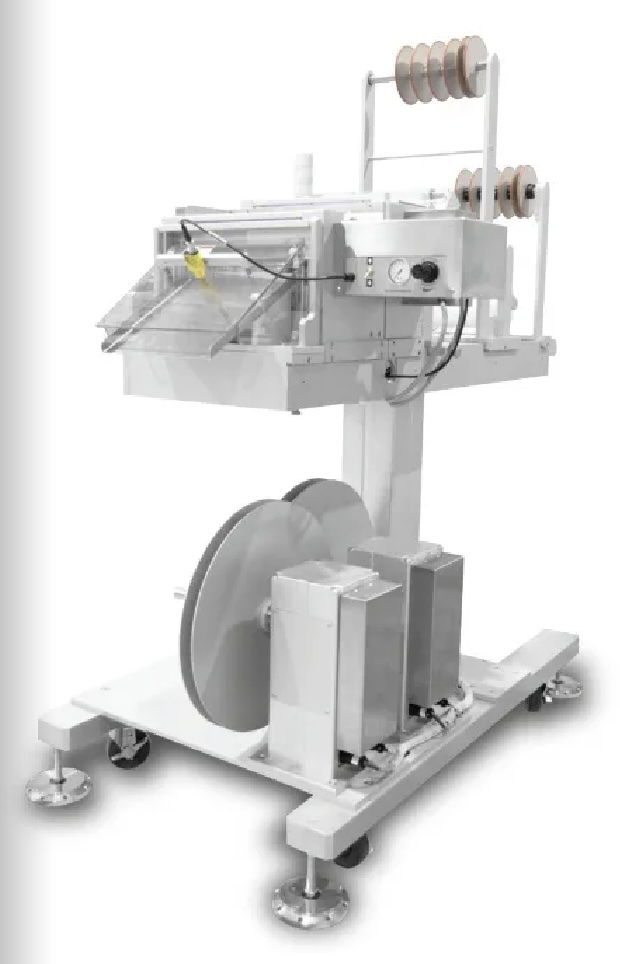

Modular cutting assemblies overcome these issues. Instead of a large, purpose-built machine that must be matched to a single production line, this modular approach consists of different "building blocks" that you can easily add to new or existing production lines. Available for a wide range of cutting and slitting tasks, you can mix and match these modules, which are designed for various materials — from foils to nonwovens. The end result is a flexible and competitively priced cutting assembly, perfectly tailored to its application.

This modular approach unlocks many benefits, lowering the time it takes to source the equipment, reducing costs and down-time, supporting faster change-overs, accelerating response times for custom products - and much more. The following article takes a deeper dive into this simple, yet innovative technology.

W hat Are Modular Cutting Assemblies?

hat Are Modular Cutting Assemblies?

Instead of an expensive custom build machine that is matched to a single production line, modular assemblies feature a mix-and-match, building-block approach.

For example, you can seamlessly integrate unwinds, slitters, traveling knife assemblies, accumulators, stations for laminating, cut-to-length and perforating tasks, and rewinds to handle all types of films, nonwovens, paper products, absorbent materials, foils, laminated materials and high-performance materials.

Traditionally, to deploy a custom machine with some combination of these functions requires a high degree of custom engineering, driving cost and time. On the other hand, modular cutting assemblies offer these capabilities as standard modules for fast, easy and cost-effective installation and removal. Modules are also available as standalone or in-line units.

The Many Benefits of Modularity

Of course, the high-speed dedicated machine still has its place — particularly for high-volume operations that handle millions of products weekly or monthly. Many companies, however, don't deal in such high volumes, requiring up to 100,000 to a million products per order. For these companies, it doesn't make sense to invest in such high-speed machines. The investment is larger, the machines are more complex to use and operate, and there is a long lead time to acquire the machines. From the time of the purchase order, it can take a year, sometimes even longer, to procure delivery.

Here's a rundown of some of the other benefits of this modular approach:

- Modular cutting assemblies reduce costs — sometimes by as much as 50 percent compared to purpose-built equipment.

- These assemblies support operations with a high degree of customization, as well as those that need frequent changeovers. Operators can simply install, remove or turn off individual modules.

- Modular cutting assemblies are flexible and support more agile manufacturing. You can integrate the equipment into existing production lines or as part of new ones. You can also mount the modules in any position.

- Integration is easy — simply install and start using.

- These assemblies support a wide variety of material types, even difficult ones like laminated plastics, adhesive-based products and high-performance materials.

In addition to their use as standalone and in-line units, cutting modules can be combined with innovative frame technology to make designing an entire machine quick and easy. The frame can handle many different modules, which easily mount into place. In some cases, the frame is pre-wired and even includes quick-connect connectors for power and air. A master control panel monitors the process, providing control over the system, as well as an ability to add or remove modules as needed.

Ideal Industries For Modular Cutting Assemblies

In addition to converting applications that focus on feeding and cutting flexible films, foils, composites and other materials, modular assemblies are ideal for:

- Machine builders.

- Medical device manufacturers.

- Packaging, including in the pharmaceutical, personal care and food industries.

Modularity in Action

Modularity in Action

Here are some application examples that showcase the ways companies have benefited from this innovative modular cutting approach. In the first example, a manufacturer needed to cut and slit metal foil capsule blisters from roll form into precise pieces. Instead of investing time and money in a large-scale, custom-engineered cutting and slitting machine, the company opted for a modular assembly consisting of slitting and cut-to-length stations.

First, the material enters the assembly from a thermoforming machine, then travels through a dancer accumulator under a set of idler rollers. A sensor automatically pauses the unit if it doesn't detect the presence of any material. Next, a set of nip rollers pulls the material into the slitter station. After the capsule blisters have passed through the accumulator and slitter assembly, the unit feeds them to the cut-to-length station, where an up-cutting knife cuts the material with an accuracy of +/-0.38 millimeters (mm) — or 0.1% the cut length. The product then falls down an exit chute. In this assembly, all the components were mounted on a common aluminum plate, while the unit itself was mounted on an adjustable equipment stand for ease of use.

In a second application, a manufacturer deployed a continuous-process cut-to-length system with slitter and stacker stations for a rubber material with a thickness of 0.25 to 1 mm. The material, pulled from an existing production process, travels over a set of idler rollers in a dancer assembly, while an edge guide system ensures the material lines up with the slitter station. The sheer cut slitter station then slits the material into 17.5-mm-wide strips, as edge trim is removed from the process. The material then travels over a set of idler rollers to the cut-to-length station. Finally, grippers place the cut product onto a stacking tray. The unit continues in this way at a speed of 20 cycles per minute.

Here are some additional examples of the modular approach in action:

- A personal care product manufacturer switched to a modular machine consisting of 17 cutting modules. The company received the machine in 12 weeks at a fraction of the cost — and time — of the monolithic alternative.

- One manufacturer uses a modular cutting assembly to produce adhesive bandages with cartoon characters on them, meeting the required volume of 20 boxes a minute.

- A mouth guard manufacturer uses a modular machine to punch holes and cut materials to length once the materials exit an extruder. The machine even stacks the material on a conveyor in quantities of 50.

- One manufacturer uses a modular machine to cut an elastomer material with 0-tension unwind. The machine slits the material to width, then rotary die-cuts it within three thousandths of an inch of accuracy.

Unlock the Benefits of Modular Systems Today

Instead of deploying large, inflexible and custom-engineered monolithic machines, integrating standard cutting and slitting modules can reduce time and costs,

improve manufacturing agility and minimize downtime — particularly for low- and medium-volume converting applications. This innovative solution also ensures your cutting and slitting operations meet the exact needs of your application, ensuring you get to market quickly without breaking the bank.

About the Author

Andy Zucaro, President of AZCO Corp., has a B.S. in mechanical engineering from Rutgers University. AZCO designs and builds equipment that feeds and cuts flexible materials. Founded in Andy's basement in 1983, today AZCO products are sold to the world's largest corporations in addition to startups that bring innovative products to market.