The Importance of Safety, Quality, Delivery and Cost

- Published: July 24, 2023

Deciding When to Automate

By Jay Roth, Director of Sales, Elsner Engineering Works, Inc.

How do you know when it is time to automate? Many look to the ‘Lean’ principles of Safety, Quality, Delivery and Cost. These are valid in choosing which operations to automate in your converting process.

How do you know when it is time to automate? Many look to the ‘Lean’ principles of Safety, Quality, Delivery and Cost. These are valid in choosing which operations to automate in your converting process.

Safety is an easy one. Although I still see some glaring hazards occasionally, OSHA has done an excellent job of establishing workplace guidelines to take care of the obvious potential for injury. Where the work comes in is determining which tasks border into repetitive motion, fatigue or even just boredom. Distracted workers can find ingenious ways to cause injury when they are not paying attention to even the safest tasks.

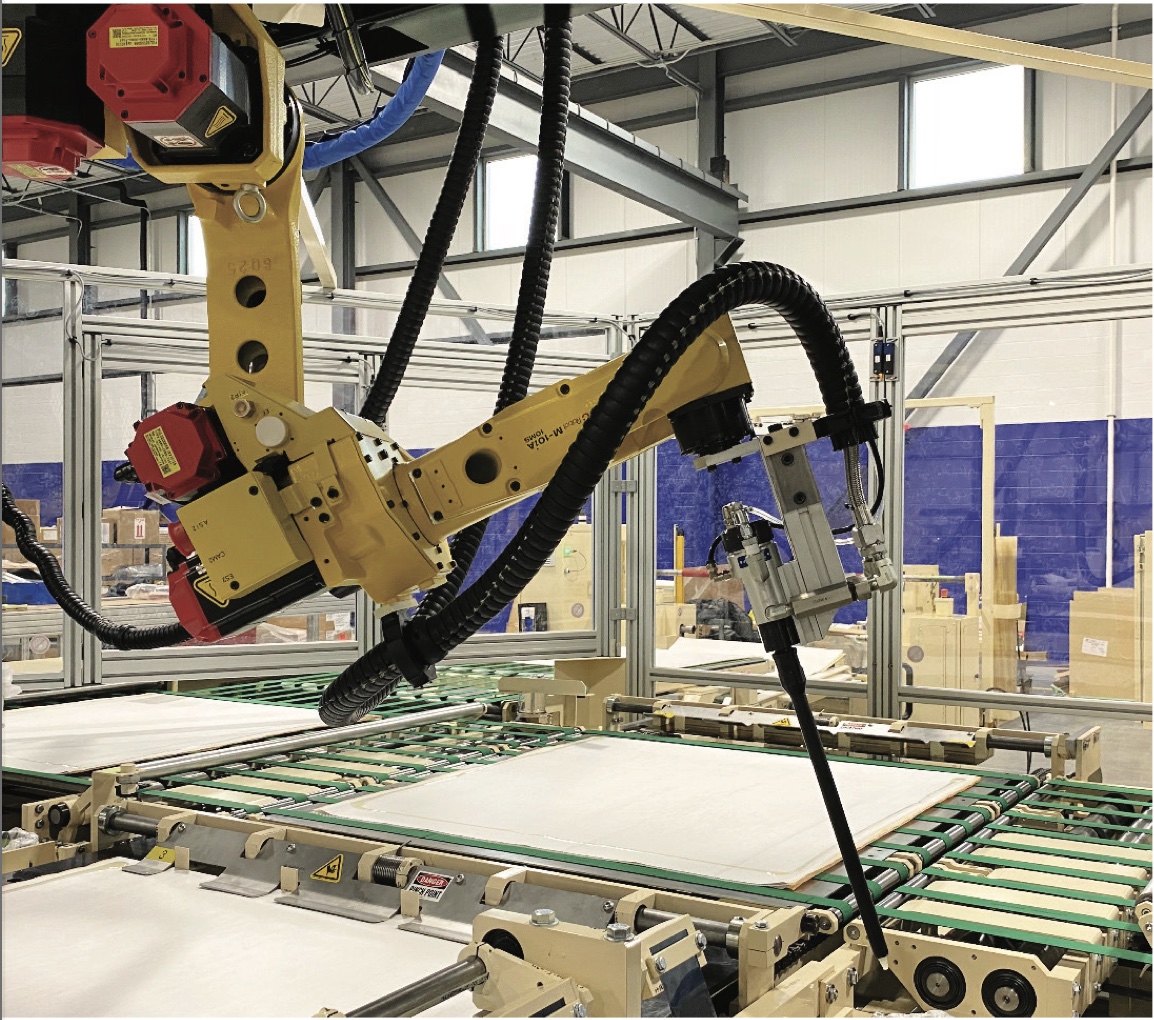

Quality. I have much respect for the craftsmanship some people put into their work. Many find it hard to give up on a process that they have perfected over their career. However, we must know when technology can move us forward. A robot can complete a task over and over again with extremely high repeatability. Consider the placement of glue beads in the construction of spiral wound filtration elements. Each element can contain more than 20 of the same repeat pattern. When applying by hand, we are naturally going to see at least minor variation. This leads to an open tolerance of what is acceptable. With a robot, the tolerance is tight and allows us to reduce waste in the final product.

Delivery. We have entered a new era of lead time and delivery expectations, and I have heard every excuse in the book for why parts, projects and even quotations are taking longer than ever before. The most repeated challenge is available labor. Whether it is a health concern, desire to work remotely, competitive job markets or lack of skills keeping people at their posts is an everyday concern in manufacturing today. It may sound cold, but machines don’t get sick, they don’t have to worry about which days their kids have off school, they are already at work when the weather is bad and they don’t mind running a double shift when needed.

Removing reliance on human operators adds to predictability and smooths the production cycle. We should no longer fear being replaced by robots, and we need to accept that automation improves our lives. I am sure the operator manually stuffing rolls of wipes into a canister would prefer a quality control position. I bet the operator standing in front of his single manual machine all day would love the opportunity to manage a work cell of three or four machines where he simply needs to keep materials stocked.

Cost. It can be tricky to determine the fully loaded ‘cost’ of a product. Salary or hourly rate of everyone touching a product as its made is the most visible adder. We also need to consider the rest of a product’s burden on the manufacturing process. We must ensure that we are truly capturing the time spent on paperwork, material handling, supervision, sales and marketing, and even opportunity loss (what are we turning away or not doing to complete this effort).

Looking beyond the overall gain in revenue is easier when we consider all contributing factors. That hefty machine price tag might give some sticker shock at first, but weighing in all aspects can bring it into reason. Many are looking to establish ‘lights out manufacturing’ of their processes. The salaries and human costs (almost) go away if we can leave a machine running after the 5 o’clock whistle blows and our production team heads home. Of course, this is not for every application, but I think most can strive for at least lowering the human per product or machine ratio.

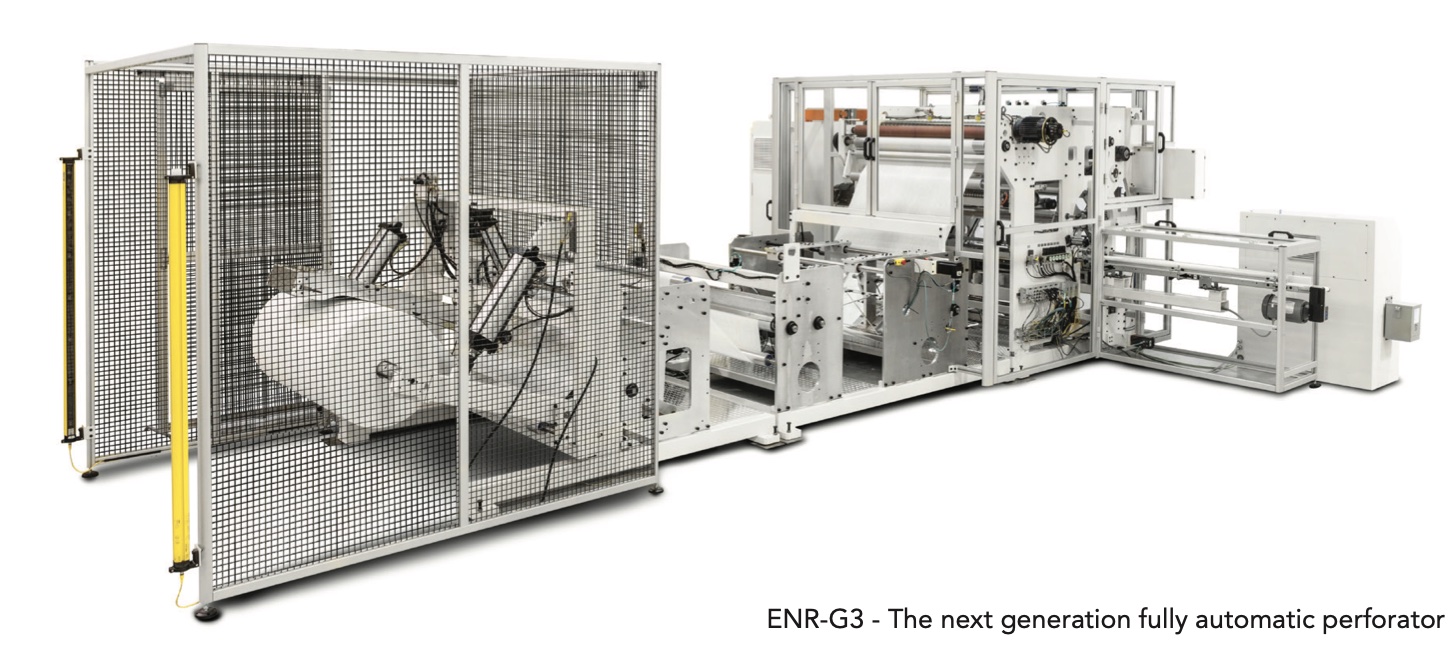

As machine designers and builders, we work closely with our customers to reduce bottlenecks in their process, improve quality, get cost out of commodity products and improve employee satisfaction. We appreciate being involved from the start of a process review and working together with our customers and their front line employees to create machinery that gives us all satisfaction.

About the Author

Jay Roth has more than 25 years of service with Elsner Engineering Works, Inc. With degrees from The Pennsylvania State University in both Electrical and Mechanical Engineering Technology, Jay is second-generation employee of Elsner.

Jay began in the machine shop, attended school at night, and worked his way into the engineering department. After more than 10 years as a machine designer, combining mechanical and electrical skills, Jay moved into the sales arena and now oversees the sales team and assists with other key areas of the company.