Properly Select a Web Guide for Your Operation

- Published: July 01, 2021

Web guide selection and installation tips

By Aravind Seshadri, President Roll-2-Roll Technologies LLC

Correct selection and installation of web guides is important and shouldn’t be overlooked

Correct selection and installation of web guides is important and shouldn’t be overlooked

Web guides are typically worry free once they are up and running. However, selection and proper installation of a web is critical to ensure that the web guides are worry free. With a variety of web guides available in the market it is necessary to understand a few fundamentals to make the correct selection. In this article a few handy tips and rules of thumb are shared to make your installation easier.

Importance of proper roller selection

Roller Diameter

The diameter of the roller is dependent on the web speed and the type of material.

- Larger diameters are necessary for high web transport speed. The larger diameter reduces the rotation speed or revolutions/minute (rpm) of the rollers. Lower revolutions/minute reduces: the bearing wear, issues with eccentricity, issues with balancing, etc.

- Thicker webs or composite webs may require larger diameters to increase the radius of curvature necessary to wrap the web around the rollers.

- Thin and light materials (low modulus webs) on the other hand may require low inertia (aluminum or carbon fiber rollers) with low friction bearings to reduce any drag from the roller.

Surface Roughness and Smoothness

The smoothness or the surface roughness of the rollers also play a critical part in web guiding.

- Grooved rollers help eliminate air entrainment. Especially with non-porous webs such as plastics, grooved rollers help with better traction on the web.

- Smooth rollers on the other hand may be needed for delicate webs such as thin foils. Grooved surfaces may create a permanent impression on the foils because

Type of Web Guides

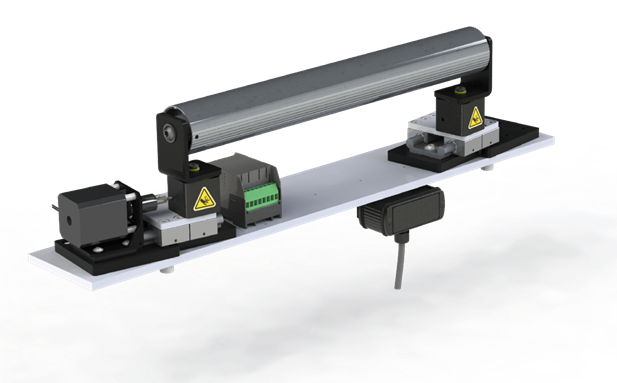

Depending on the location where the guiding is required, there are four different types of web guides available. Displacement guides, steering guides, unwind guides and rewind guides.

Displacement Web Guides

Displacement guides, also known as Off-Set Pivot guides, should be chosen as the first option wherever possible. If properly installed, the displacement guides impart the least amount of stress on the web. These web guides position the web by directly displacing the web rather than bending the web. Hence they are the best choice for guiding. Situations where displacement guides cannot be used include: correction after a long span, locations with web wrap constraints, and locations with space and installation constraints.

Steering Guides

Steering guides are ideal for situations where guiding after a long span is desired. These guides bend the web that enters the steering roller(s). The magnitude of steering depends on many factors including: web speed, web stiffness, guide installation (raceway angle), entry span length, etc. Since the steering action imparts stresses on the web, it is very critical to properly install the web guide to prevent web breakage.

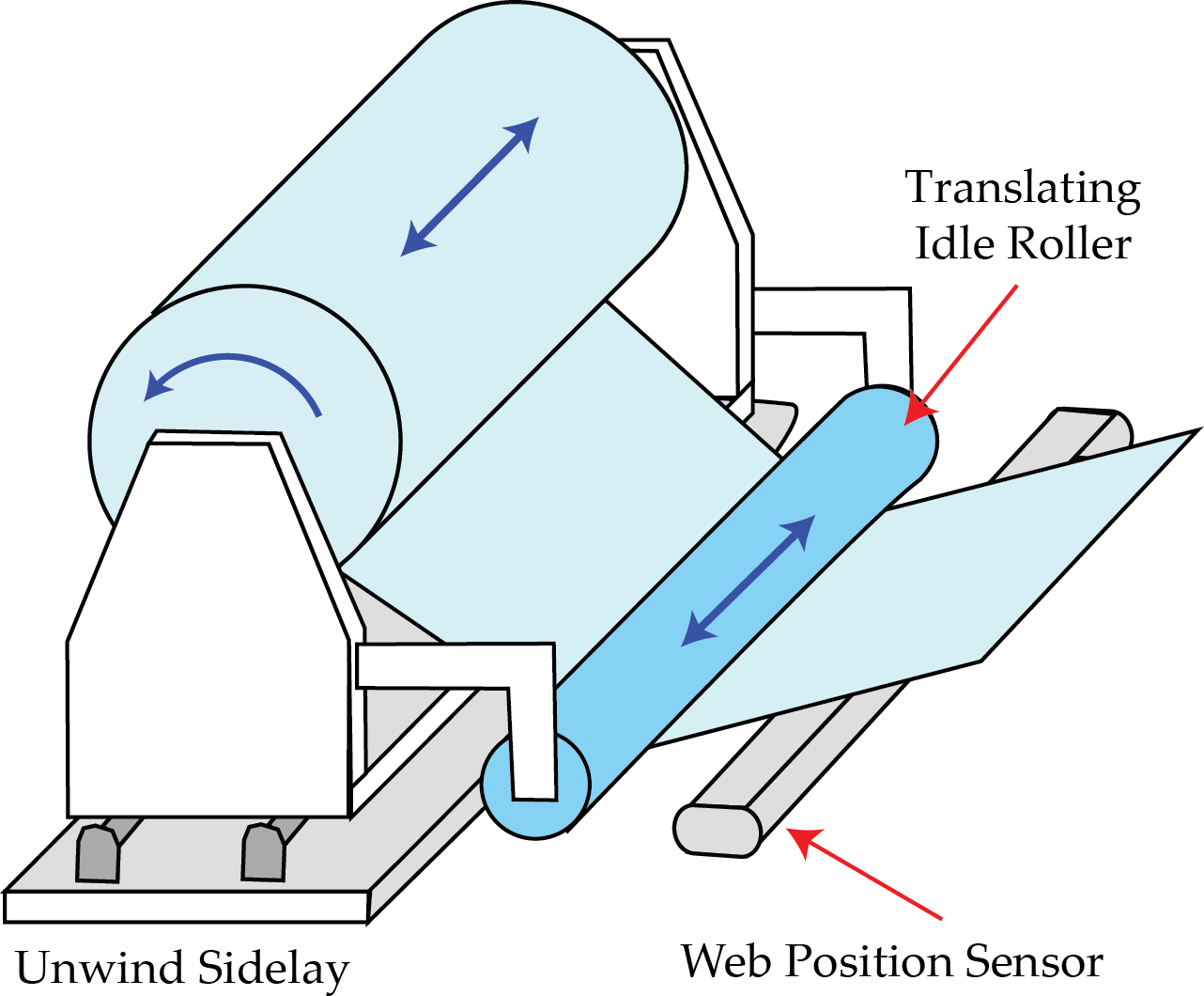

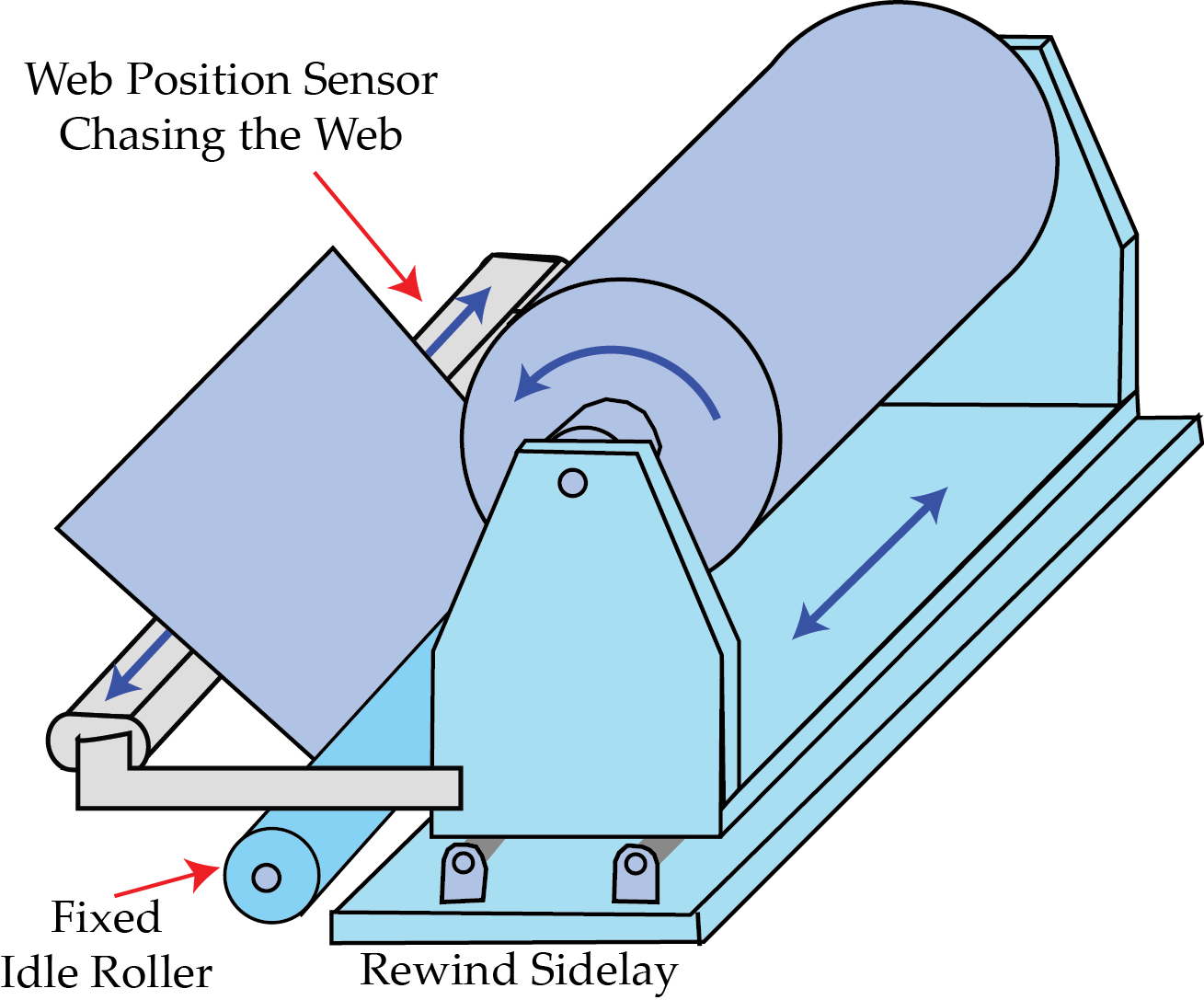

Terminal Guides

Unwind and rewind guides are used at the entry and exit of the machine. Typically the roll stand, that supports the raw material roll, is mounted on precision linear raceways. to minimize the friction necessary to move the guides. These terminal guides are simple, however the dynamic response is limited because of the force required to move the roll inertia.

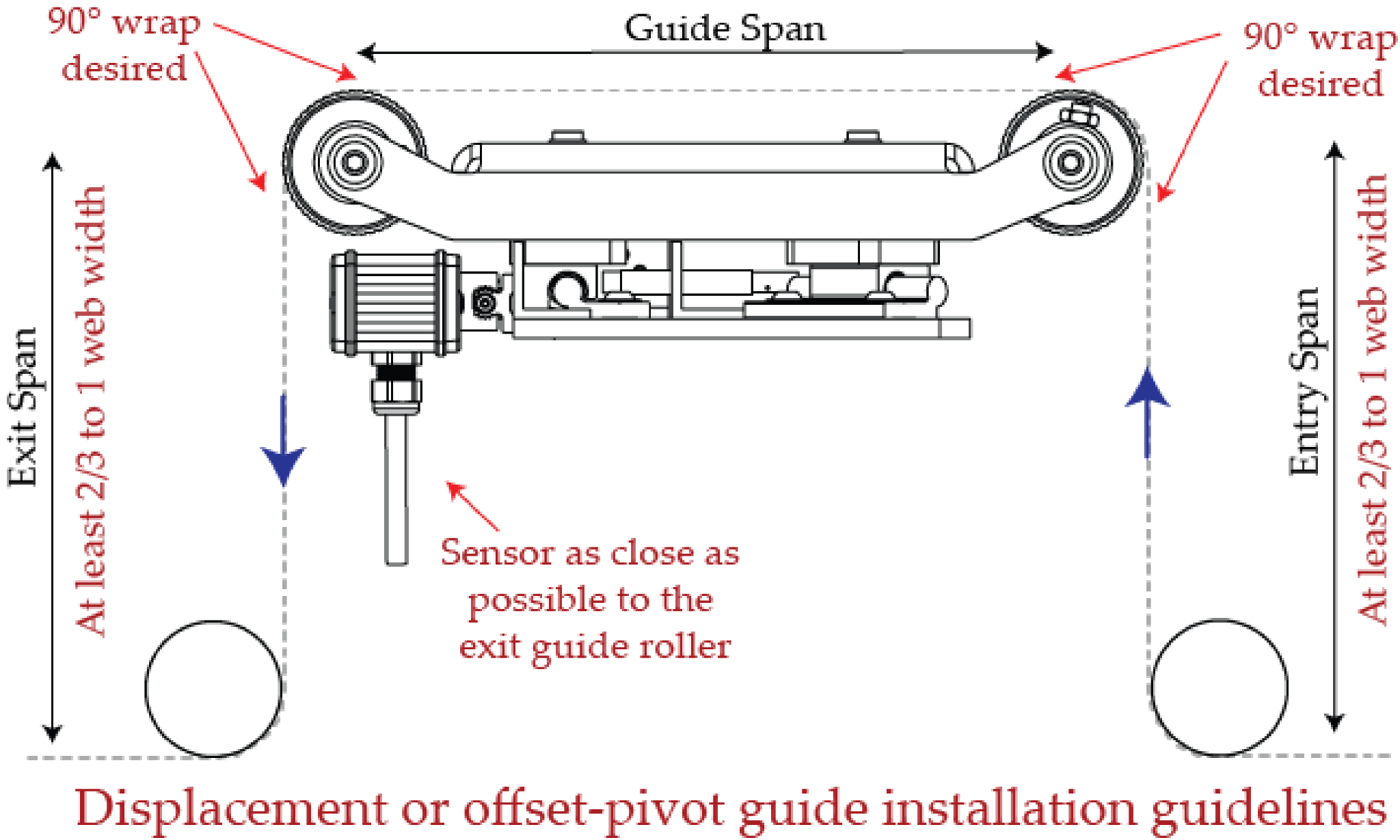

Proper Installation: Displacement Guides

Entry and Exit Spans

Displacement web guides can have short entry and exit spans which may be of different lengths. A minimum of 1 web width is necessary for most applications. However, long spans lengths are needed for stiffer materials such as metals.

Web wrap

A 90° wrap at the entry and exit of the guide roller is ideal. This 90° wrap enables pure twisting in the entry and exit spans, thereby imparting the least amount of stresses in the web. A small deviation from the ideal 90° wrap is acceptable. Apart from bending and stressing the web, the deviation from normal condition also affects the lateral correction speed.

Entry and exist span lengths: Steering Guides

Entry and Exit Spans

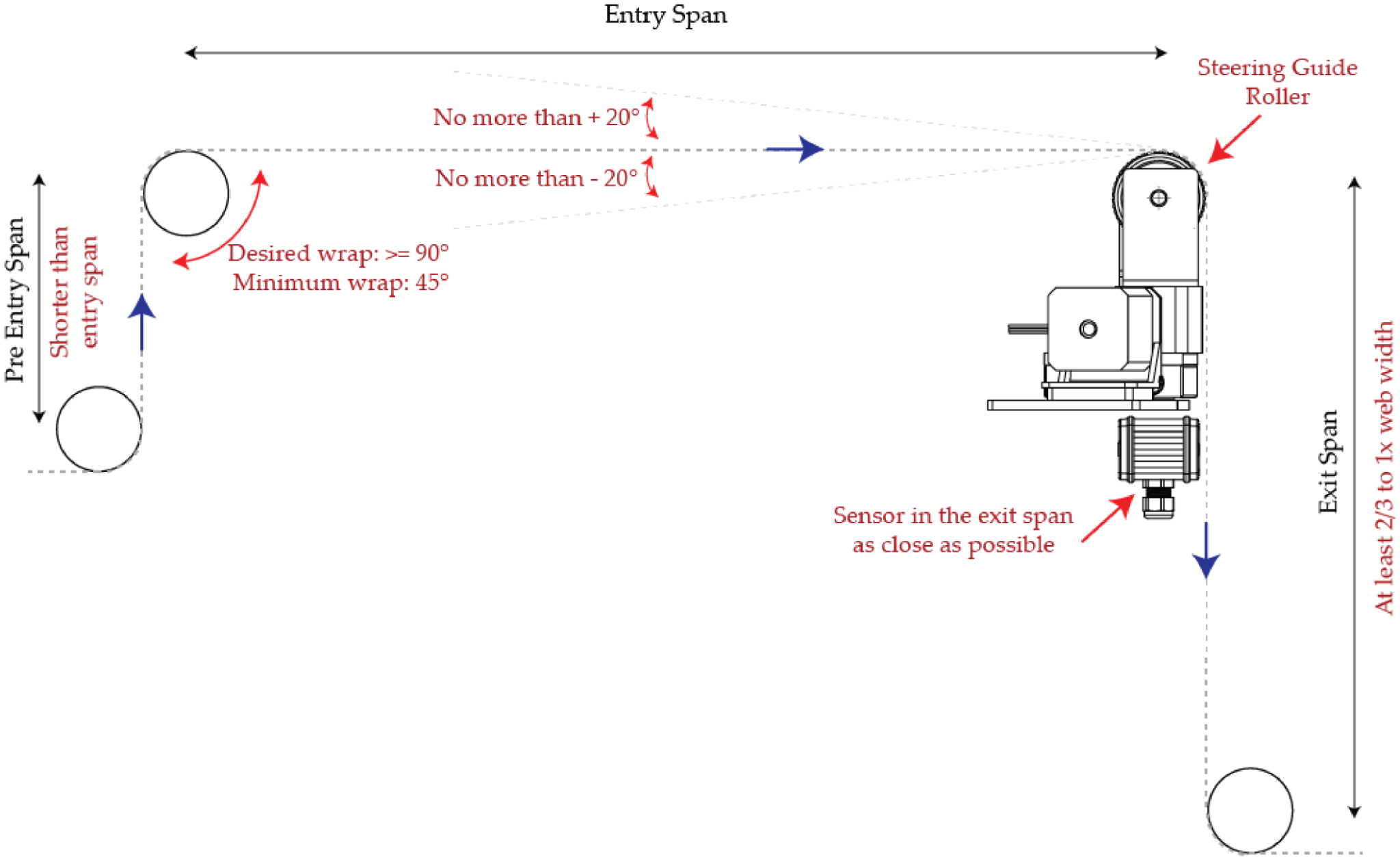

Steering guides require long entry spans. Depending on the stiffness of the web, the entry span length required may be from 3x to 10x the web width. Too short of a span may result in slack and tight edges or web wrinkles.

Since the steering guide bends the web, the moment transfer from the steering action can travel both upstream and downstream of the web guide. Hence the pre-entry, entry and exit span lengths are important design parameters. A rule of thumb is to have a pre-entry span shorter than the entry span. And the exit span is at least 1x web width.

Web Wrap

At least 90° wrap at the exit of the steering guide roller is ideal. Because of the upstream moment transfer, the pre-entry roller may also require a wrap of no less than 45° and an ideal wrap of 90°. Additionally the plane of the entry span should be parallel to the plane where the roller platform moves. A plane change of no more than ± 20° may be acceptable.

Types of Guiding

Web Edge Guiding

Web guiding is usually referred to as guiding on a single edge of the web material. This is the most common type of web guiding. This method is suitable when the web width does not change during and between runs. Either the operator side or the drive side edge can be guided to the desired location based on the sensor position.

Center Guiding

Center guiding is a preferred method of guiding when the edges of the web are uneven or if the width of the web changes during or between production runs. Instead of positioning the web based on one edge, the centerline of the web is guided. The center position is determined by using two sensors, one on each edge of the web.

Line Guiding

In certain applications, such as slitting of printed webs, the web may be guided based on the position of a printed line. The line is a fixed reference for the position of the print on the web. Since the position of the print on the web with respect to the web edge may vary between runs, the printed line acts as the fixed reference for guiding the web. Most often a camera based solution is used to guide the web based on the printed line.

Contrast Guiding

Similar to line guiding, the web may be guided based on a contrasting feature on the web. A printed contrast or a contrast due to a coating process can be used as the reference for web guiding.

Web Guide Oscillations

Finally, in some applications the web is deliberately made to oscillate back and forth. Most often the oscillations are necessary to prevent any gauge band buildup while rewinding a non-homogeneous web or a composite web or a web with gauge variations along the width. An ideal way to create this oscillation is to guide the web to an oscillation reference. Primitive systems would oscillate the web edge sensor while the web guide moves the web to track the oscillation sensor position. Modern systems can create an oscillating reference digitally.

Finding the Best Web Guiding Equipment for Your Operation

As we search for the most appropriate equipment for our operation, we are faced with the task of selecting from myriad options based on technical data and specs. Through these data, measurements of accuracy, precision, linearity and resolution, manufacturers are trying to present the benefits of their products based on the device’s performance profile. However, sometimes what appears to be the best offer, based on what looks to be the best technical data, might not really be the best. The technical data can even be irrelevant information when considering performance.

The question that must be asked is, does my operation require a high-performance web sensor and guiding capacity? For operations running at lower speeds and with wider tolerances in their web positioning, the answer is probably no. These operations can get by with not having to worry about calibration of their sensors when running different materials. However, operations that run at faster speeds requiring precise placement of the material, calibration will be a must if they are using sensors that operate under a blocking principle. Of course the trade off is lost production time in calibrating sensors, but it is the only way that an adequate accuracy and precision can be achieved. Certainly, misplacement at higher speed will turn into greater amounts of wasted materials, and important losses in uptime. There is definitely a need for systems that are not only accurate and precise, but also that eliminate the need for calibration of the web guiding systems to reduce downtime.

About the Author

Aravind Seshadri is president and co-founded Roll-2-Roll Technologies LLC in 2013. Aravind is the co-inventor of the intellectual properties used by Roll-2-Roll Technologies LLC and was the principal project associate involved in the design, development, testing, and validation of the technologies used in our lateral guides. He earned an MS degree (2007), and a Ph.D. (2013) in Mechanical and Aerospace Engineering from OSU, and was awarded the Graduate Research Excellence award for both degrees.