Material Properties, Testing & Applications: Part 2

- Published: May 13, 2022

By Neal Michal, Principal, Converting Expert, LLC

Introduction

Last month we discussed tensile testing and how your material properties relate to common customer complaints. This month we will discuss 12 aspects that will directly impact your tensile testing results.

Strip versus Grab Tensile Method

There are two tensile test methods: Strip and Grab. Strip method — The complete width of the sample coupon is gripped in the jaws of the testing machine. Grab method — Only the center portion of the sample is gripped in the jaws. Grab tensile tests only provide reliable results for ultimate tensile strength. Strip tensile tests are preferred because they can provide all of the material properties.

MD versus CD

Machine direction (MD) tests are more common. The coupons are oriented along the MD. Cross machine direction (CD) tests are oriented across the width of the process. It is normal to see significant differences in MD versus CD tensile values due to how the web was formed. In general, the ratio of MD to CD modulus will increase with the speed of the web forming process.

Length to Width Ratio (L/W)

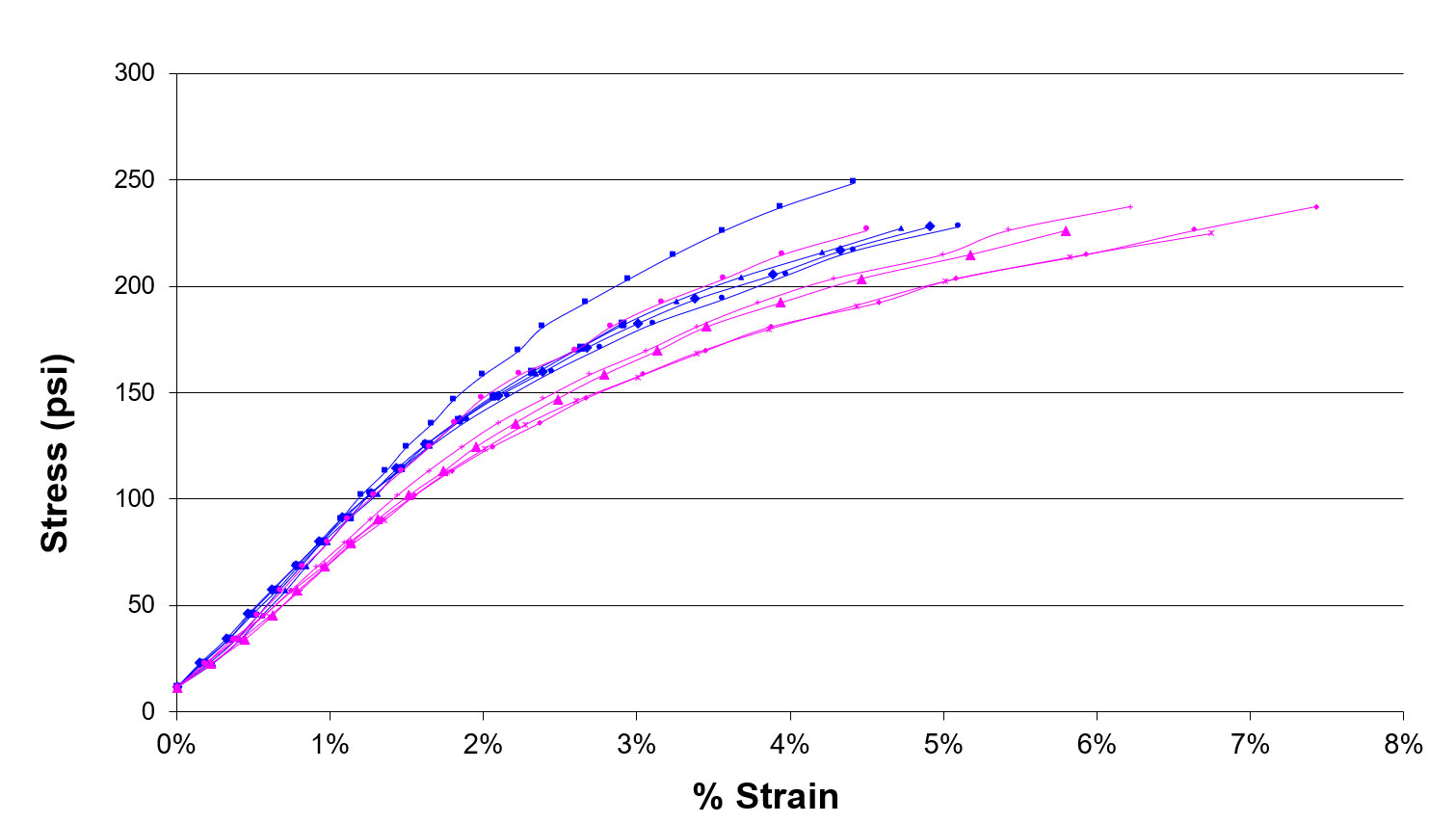

A cursory review of standardized tensile tests reveals that the length to width (L/W) ratio can range between 0.75:1 to 4:1. Shorter L/W’s will increase the measured values for modulus. This is due to the “end effect” of the grips. The web is effectively stronger adjacent to the grip. Longer L/W’s will allow one to detect fine distinctions between different populations of materials as shown on Figure 1.

Figure 1

Stress vs Strain

Coupon Size

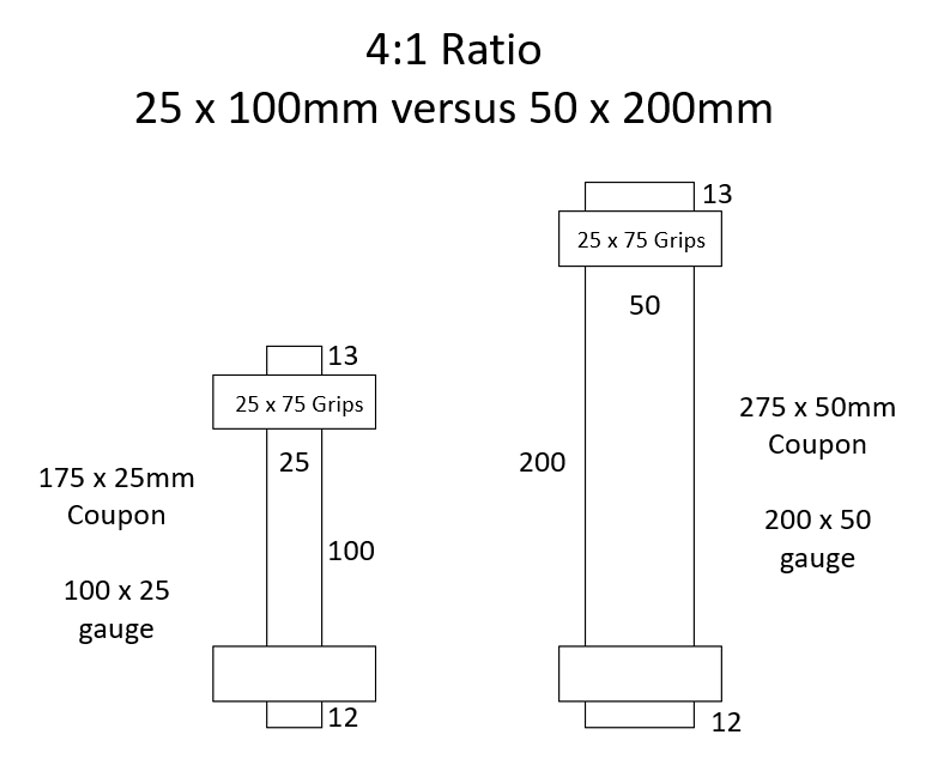

There are an infinite number of coupon sizes that can be tested for a given L/W ratio. Figure #2 shows two set ups with the same 4:1 ratio. Note that the coupon must be long enough to extend past the top and bottom grips to facilitate ease of inserting and alignment to the grips. Toughness and deformation energy will vary ~ linear to the area (L x W) of the coupon tested.

Figure 2

Two coupon sizes with a 4:1 Ratio

Slippage

There are many styles of grips. They are often selected based on ease of loading and unloading. Grips take a beating and are often worn out or damaged. Any slippage in the grip will render your data suspect at best. One can strike a line across the coupon next to the grips and look for any slippage. A better technique is to download and graph the load versus elongation data. Look for an offset of elongation with no change in load. Use grips that will not slip.

Slack versus Pretension

It is common to see slack in the coupon after it has been clamped. Any slack will cause significant variation in your results — particularly elastic limit and deformation energy. The repeatability of your tensile tests will improve if you pre-tension the coupon. This can be done manually if the operator can see the displayed load before closing the second clamp. Many tensile testers will allow one to set a low pretensioned value before the test begins.

Strain Rate

Standardized tensile tests require the crosshead to move at a constant rate of elongation. Typical units are mm/min. It is helpful to evaluate your tensile test(s) based on strain rate. Strain rate is defined by: Crosshead speed / Gauge Length / Time with units of mm/mm/min. It is common to see ultimate tensile strength, toughness and deformation energy vary with strain rate.

Cross Deckle (CD) Mass Profile

Your physical properties will vary as a function of mass. Mass will vary across the width (CD) of your process. Some processes can vary more than ten percent. It is helpful to weigh the sample before they are tested. This additional step will provide insight to the variability of your material across the width of the process.

Thru-Roll Radial Position

Material samples are typically harvested from the outside of the roll. However, your customer will consume all of the material. Your material properties will vary as a function of the stored stress and strain within the roll. Thru-roll tests are required to understand the magnitude of change. For a given roll density your physical properties will display a unique thru-roll profile that should be repeatable from one campaign to the next.

Harvest versus Test Time

The physical results for elastics, oriented films, nonwovens and tissue will be directly impacted by the dwell time from when the coupon was harvested to the time it will be tested. It is a best practice to select a convenient time to test the samples that can be reliably held constant.

Aging

Your physical properties may change significantly over time. For example, many nonwovens become brittle over time. - elastic limit, toughness and elongation at failure will drop significantly, while modulus will increase with aging. Aging studies are required to document how your material properties will change.

Registered versus Non-Registered

Testing elastic webs can be challenging. Often the sample is removed from the roll and loaded into the tensile tester relaxed. You can dramatically reduce variability in your test results by marking the gauge length on the web before removing the sample from the roll. These marks are then used to register the coupon to the clamps.

Conclusions

Strip tensile tests with L/W at or greater than 4:1 will improve your ability to detect important shifts in your material properties. The values of your test results will vary as you change the coupon size, L/W ratio, or strain rate. Use pre-tension to reduce variability in your results. Audit your grips for any slippage. You should correlate the relationship between coupon mass, cross deckle & thru-roll position to fully understand your physical properties. Special care should be used when testing viscoelastic or hygroscopic webs as it relates to testing time and roll aging. Coupons of elastic webs should be registered to reduce testing variability.

Next month, we will discuss practical applications for tensile testing with real-world case studies.

ABOUT THE AUTHOR

Neal Michal of Converting Expert is a well-known authority in web handling, process design and optimization. He worked with the Web Handling Research Center for 20 years. Currently serving as a technical advisor with AIMCAL, he can be reached at neal@convertingexpert.com or through www.convertingexpert.com.