Product Measurement | Monadnock Reduced Length Losses with Accurate Sensors

- Published: March 01, 2017

Nonwovens converter achieved fast ROI with PROTON InteliSENS speed and length gauges.

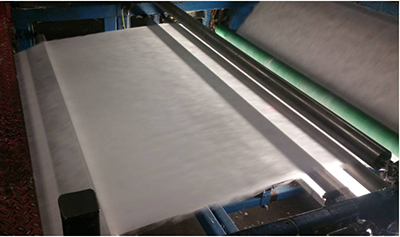

Founded in 1998, Monadnock Non-Wovens (MNW), Mount Pocono, PA, has extensive experience in meltblown and specialty nonwovens technology. Its products serve the air, dust, and liquid filtration markets, as well as the health and safety, automotive, and appliance industries.

The converter also offers customers the value-added processes of charge enhancement, laminating, and calendering. Its products can be enhanced with unique additives, colors, resins, and treatments to create customized, high performance value-added properties.

MNW’s product innovations meet or exceed the technical specifications often demanded by its customers. However, for accurate speed and length measurement on multiple nonwoven lines and calendering operations, the products represent a unique series of challenges as follows:

- Contacting sensors require a flat surface for effective operation, so accurate speed and length measurement is not easily possible due to the uneven surface structure of the nonwoven products.

- Nonwovens are extensible in nature, so any change in the on-line draw directly affects both the final basis weight and thickness qualities of the product.

- Contacting mechanical sensors may cause surface damage or impression.

MNW wanted to reduce length losses through its conversion processes. It also needed to eliminate either product give away or the delivery of shorter-length rolls than customers ordered, which can lead to expensive customer complaints.

PROTON Sensors Chosen

Following market research, MNW chose InteliSENS SL non-contacting speed and length sensors from PROTON Products to help solve measurement challenges for its multiple lines and calender. PROTON’s Doppler measurement technique is said to provide extremely accurate measurement performance (better than 0.05%), irrespective of the products surface structure, with no maintenance compared to conventional contacting wheel/roller systems.

MNW recognized the potential value of this measurement in terms of quality, accuracy, maintenance, and return on investment, while at an affordable price. The InteliSENS SL sensors were installed on all of MNW’s lines, replacing the contacting sensors. They were positioned before the roll windup to measure the exact length of product that is wound onto the roll.

Paul Stehlik, MNW’s engineering & facilities manager, said, ““PROTON’s InteliSENS speed and length sensors were easy to install and integrate. Their accurate measurement means they have not needed any recalibration and have eliminated length-related product losses and customer claims.”

Stehlik reports the sensors have operated reliably for more than ten years, surviving in harsh industrial environments without needing any maintenance or recalibration. The sensors use industry-standard Bluetooth communications and are interfaced to the plant’s Modbus units.

Accurate Results

Stehlik says MNW has benefited from accurate speed and length measurement in a number of process, quality, and productivity areas. First, MNW’s manufacturing operations comprise a number of discrete processes where the product is transferred from the base machines through converting operations (such as occasional calendering) with each step adding value. Now, with accurate length measurement, the rolls can be made to a desired length to avoid losses due to slab-off, product that is cut off and wasted as it proceeds through the manufacturing process.

Second, customers expect to receive exactly what they pay for in terms of length delivery. MNW’s previous conventional speed and length transducers suffered from lack of accuracy due to the product’s surface structure. Because PROTON’s IntelliSENS SL sensor simply measures the speed and length of the moving sheet, it is immune to the surface structure and also eliminates contact damage.

Finally, PROTON’s IntelliSENS sensors guarantee that MNW’s customers receive an accurate length product made to the correct basis weight and thickness quality specifications.

MNW is delighted with the performance of its InteliSENS SL sensors. According to Stehlik, “They literally paid for themselves in weeks!”