Minimizing Waste in Extrusion Coating

- Published: December 09, 2024

Optimizing Efficiency and Sustainability

By Kate Donahue, Marketing Manager, The Griff Network

Extrusion coating is a key process in modern manufacturing, seamlessly integrating extrusion and lamination to produce high-performance composite materials. This technique involves applying a molten polymer onto a continuously moving substrate. Products of extrusion coating are used in a wide range of industries, including packaging, automotive, construction and more.

The benefits of extrusion coating include enhancing a base material's barrier strength, durability and printability. However, alongside its benefits lie challenges. One of the largest challenges in the extrusion coating process is managing and reducing waste, a critical aspect for economic efficiency and environmental sustainability.

Understanding the Extrusion Coating Process

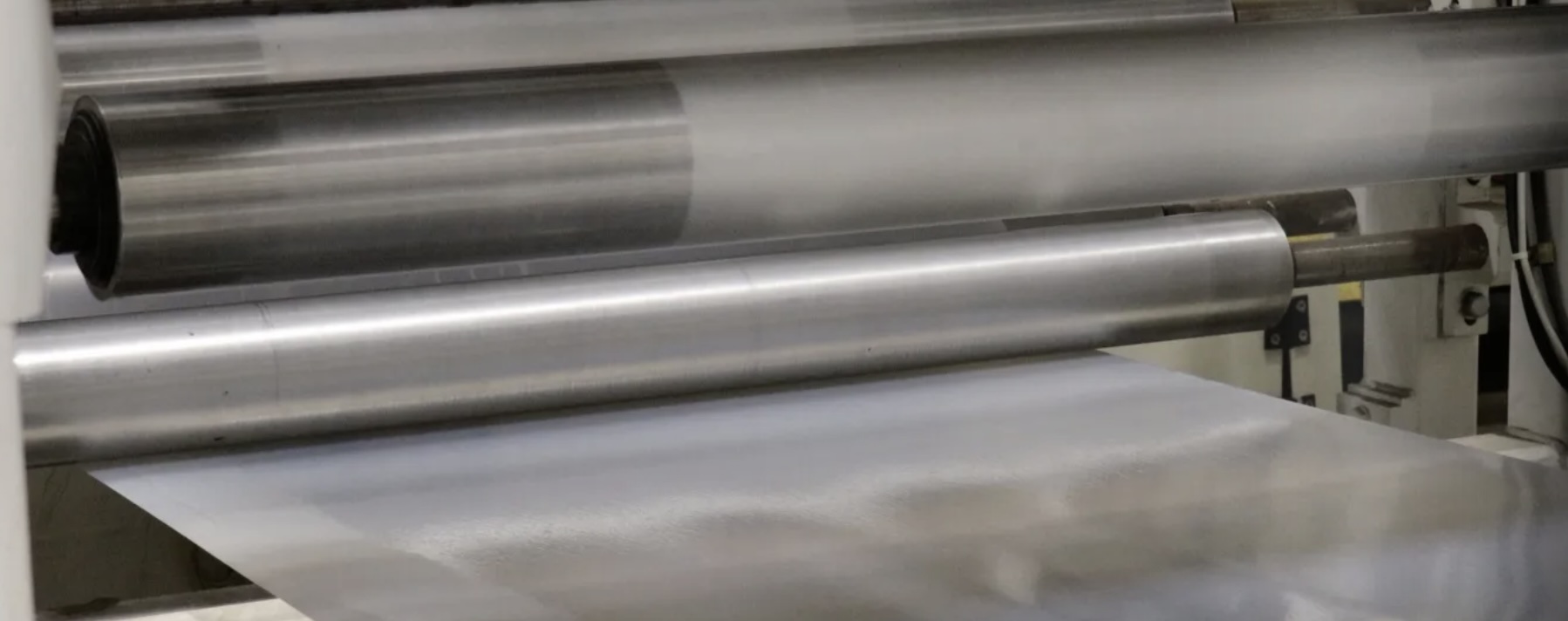

The extrusion coating process begins with raw polymer pellets fed into an extruder, where they undergo heat and pressurization to become fluid. This molten polymer is then extruded through a flat die onto a moving base material, passing through a nip of two counter-rotating rolls. Substrates commonly used typically include paper, cardboard, foil and a variety of films.

After the application, the coated substrate moves through cooling rollers to solidify the polymer layer. This process results in a composite material with benefits for industrial applications in flexible packaging, laminates, labels and more.

Key Causes of Waste in Extrusion Coating

There are several factors that contribute to waste during the extrusion coating process. One key factor contributing to waste during the extrusion coating process is losses during startup and shutdown. During each production cycle, startup phases are utilized to achieve optimal coating conditions. Additionally, there are shutdown procedures that often involve purging to prevent polymer degradation. These processes typically result in wasted material.

Trim scrap is another key cause of waste in the extrusion coating process. During the extrusion coating process, excess polymer is trimmed from the substrate edges. Typically, the trim is discarded. The discarded trim accumulates continuously throughout the coating process and can create a significant amount of waste.

Another key cause of waste is quality control rejections. Defects, such as air bubbles or streaks, variations in coating thickness and other quality issues may render portions of the coated material unusable. Quality control rejects directly contribute to waste in the extrusion coating process.

Material losses also contribute to waste in extrusion coating. Losses can be caused by inefficient handling of raw materials, equipment cleaning procedures and spillages during transfer. These issues can contribute to overall waste.

Strategies to Mitigate Waste

Efforts to minimize waste in extrusion coating are multifaceted. Optimizing processes, improving material efficiency and implementing sustainable practices can reduce waste in extrusion coating.

- Process Optimization

Process optimization is an essential strategy to mitigate waste. Advanced control systems monitor line speed, pressure and temperature. Utilizing and installing control systems can reduce startup scrap and optimize coating consistency.

Streamlining startup and shutdown sequences can significantly reduce waste. Effective techniques include minimizing transition material and implementing efficient purging techniques. Planning production runs to minimize startup and shutdown times reduces the amount of material purged and wasted.

- Reducing Trim Waste

Another strategy to boost efficiency in the extrusion coating process is to reduce trim waste. Trim waste can be reduced by utilizing high-precision equipment. Investing in precise cutters and slitters minimizes trim widths and optimizes material usage.

Establishing recycling programs for clean trim waste reduces landfill contributions and potentially generates secondary revenue streams through recycling initiatives.

- Quality Management

Improving quality management is another important strategy for minimizing waste. Automated inspection systems can detect defects like surface imperfections or coating thickness variations. Integrating these inspection systems can minimize the production of defective products and quality issue-related waste.

Continuously monitoring substrate quality and coating parameters throughout production ensures variations are detected early and reject rates are reduced.

- Material Usage Efficiency

Maintaining material usage efficiency is crucial for minimizing waste. Improving material storage conditions and handling practices minimizes contamination and spillage. The improvements reduce material losses during production.

Using polymer formulations designed for specific coating applications enhances coating efficiency and reduces material consumption.

- Sustainability

Sustainability initiatives also play a critical role in waste reduction. Implementing energy-efficient practices, such as optimizing heating and cooling systems, reduces operational costs and decreases overall energy consumption and environmental impact.

Other important waste reduction strategies include recycling and circular economy practices. Collaborating with recyclers and suppliers to initiate closed-loop recycling systems for post-consumer or production waste materials promotes sustainability and reduces landfill waste.

Conclusion

Minimizing waste in the extrusion coating process is key for manufacturers aiming to enhance operational efficiency, uphold environmental stewardship and reduce costs. Manufacturers can minimize waste by adopting advanced technologies, optimizing processes and embracing sustainable practices. With these strategies, manufacturers can significantly reduce waste generation while maintaining high product quality and profitability.

As global industries increasingly prioritize sustainability, the evolution of extrusion coating processes will need to continue to emphasize efficient resource utilization and waste minimization. This emphasis will ensure a sustainable future for the extrusion coating process.

About the Author

With an educational background in journalism, Kate Donahue has a diverse portfolio of public relations, marketing and branding experience. At The Griff Network - known for its cutting-edge converting and toll coating services - Kate specializes in marketing release liners, decorative films, foil, laminates and packaging materials. She can be reached at inquiry@paperandfilm.com.