Sustainability: A Journey Through Coating and Lamination Technology

- Published: June 20, 2024

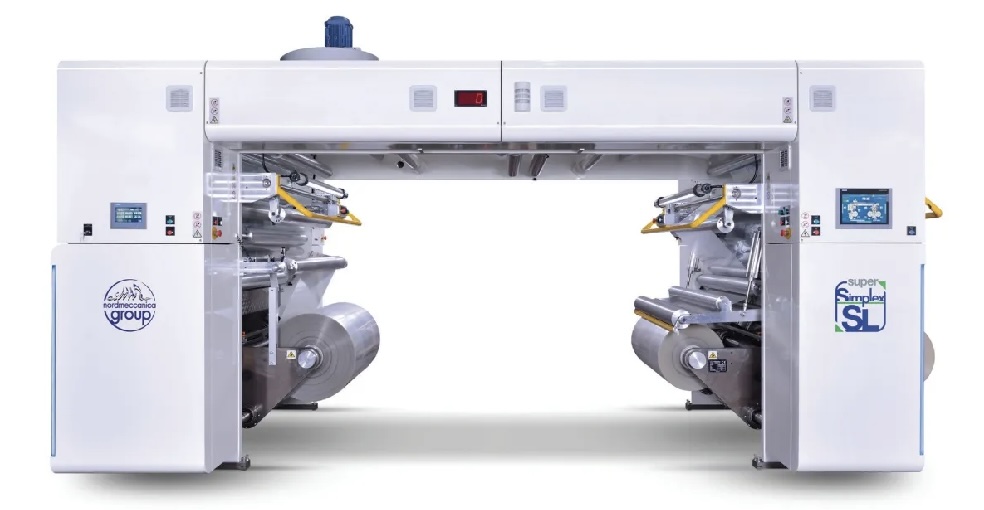

By Giancarlo Caimmi, Commercial Director, Nordmeccanica Group

The converting industry has had positive impacts on nature, developing technologies to reduce energy use in the packaging cycle, the overall carbon footprint and waste of food products (the largest contributor to solid urban waste), as well as to improve hygiene and eventually reduce overall costs.

On the other hand, our industry has room to improve toward converted products' end of life, the intensive use of energy and the emissions associated with the production processes. Attention to developing better and more sustainable technologies in our industry include the development of converted compounds that allow for higher rates of recycling such as mono-material structures — Compounds that can be recycled because they are made of a single polymer in a very high percentage.

Currently, each member of the value chain is contributing to new developments. The conversion of innovative substrates will require the machinery side of the value chain to set proper technologies, specifically on the web handling side. Similarly the development of new functional coatings requires evaluation of proper coating technologies, selection and development of innovative ones.

The involvement of the machinery manufacturer consists in providing efficient hardware solutions aligned to the requirements of innovative compounds. This is critical in coating and lamination, with such machines particularly affected by energy consumption and VOCs-related emissions.

There is a large area of innovation exclusive to the machinery manufacturer. I am referring to the improvement in the energy efficiency of the production process. Equipment involved in the conversion process is suitable to be evolved to contribute to the sustainability of the production cycle. Carbon footprints associated with the conversion process can be significantly lowered as certain innovations and design solutions are implemented.

Technical solutions that have been implemented in coating and laminating machines are mainly targeting energy efficiency and emissions reduction. Energy is predominately used in the conversion process in two forms: Electricity and heat.

Electricity is needed to feed motors, devices and ancillaries involved in the process. Heat consumption is related to technological needs associated with process handling, thermal regulations during the process and drying systems.

The reduction of electric energy consumption can be approached by the OEM through smart design first. Dimensions of the equipment and size matter. A longer web path, longer than needed, contributes to passive inertia and consequently requires the use of larger motors, with the relative increase in energy consumption.

Another important contribution is the use of low passive inertia mechanical components: Low friction bearings, high-efficiency timing belts and gears will reduce energy consumption.

In the web path of a coater or laminator there is a large number of web supporting rollers. Each idle roller contributes several grams to passive inertia. When tens of idle rollers are involved, it is easy to reach passive inertia level in the size of several pounds.

In order to manage that inertia, a larger amount of power is required. Low inertia components are obviously more expensive than generic ones but the payback is quick. It is an important topic to evaluate at time of investment.

Good machinery includes those solutions as a standard. The benefit, projected to the life cycle of the equipment, will be relevant. Modern electronics provide energy-efficient solutions. Multiple classes of energy efficiency are available and this is another aspect that should not be overlooked.

One important technology to be considered is self-generation of electricity during the production run. This is the technology of the regenerative AC drives consisting with the conversion of the kinetic energy of the motor and the associated load into electric energy.

All modern equipment is designed with motors used as breaks at the unwinds. The use of motors is motivated by the higher accuracy provided in web handling. Most of the run time, those motors are in fact acting as breaks. This is the phase during which the regenerative drive converts, or regenerates, the kinetic energy of the compound motor-load (the unwound roll, actually) into electric energy. And that energy, in the most advanced systems, is used to feed other machine motors in actual higher demand.

The benefit to the process is that an estimated 20-25 percent of electric energy consumed by the equipment is self-generated. Once again, a technical solution that pays back quickly and generates savings during the entire machine life.

Emissions is another aspect of sustainability that can be positively affected through machine design.

Coating and lamination cover multiple technologies used within the industry: Solvent-less adhesives; dry bond compounds; wet bond compounds; energy cured compounds; thermoplastics...

The solvent-less adhesive class does not require drying, consequently there are no VOC emissions. The air that is exhausted at the coating head for safety reasons, consisting in "part per billion" of monomers, is considered by most regulations pure air.

This is the reason why solvent-less lamination is growing in use in every area. A solvent-less laminator compared in efficiency to a wet or dry bond laminator may show up to 80 percent energy savings.

In the wet and dry bond processes the achievements in efficiency are connected mainly to oven design, with air ovens the most common solution. Air is heated at the process temperature and then the energy that comes with the air needs to be transferred to the coated compound to remove water or solvents during the drying process.

Here the efficiency of the drying process is associated with the oven design. The more the warm air is forced to remain in contact with the coated compound (mainly through forced turbulence) the higher the efficiency on the transfer of heat. This way the drying process will be accelerated and the oven can be reduced in length with advantages in web handling as well.

As for every heat-related process, thermal insulation is key to efficiency. A drying oven can disperse a lot of energy to the outside through radiation and convection. Thermal insulation will bring a significant contribution.

Oven air recirculation is also a contributor to efficiency. Forcing a portion of the exhausted air to circulate back to the oven under controlled percentages allows for significant energy savings. A heat exchanger down stream from the oven also increases efficiency. The use of recovered energy for secondary applications will be almost free of charge for the converter. Costs associated are always paid back very quickly.

In every process requiring significant amounts of thermal energy for process control, machine design has a significant impact. The more the energy is transferred efficiently, the lower consumption and associated costs will be.

In thermoplastics, thermal insulation plays a significant role. In machines for that conversion, thermal controls are used at every process step, starting with the melting process, continuing with the coating process and the chill roller. There will be thermal dispersions all over if the machine is missing insulations. The use of a melter-dispenser instead of large, heated reservoirs for the melted compound makes the process more efficient.

Investing in new hardware and improving energy efficiency in existing equipment through an analysis of the energy in use and the implementation of proper remedies benefits the environment and is a significant savings in costs for converters. Properly engineered equipment compared to basic alternatives may show energy savings of 50 percent or more. This not only means quicker pay back, but generates savings for the entire life of the equipment.

About the Author

Giancarlo Caimmi holds a PhD in mechanical engineering by University Federico Secondo in Italy, and has over 35 years of experience in the converting machinery manufacturing industry. Giancarlo has been the author of articles for technical magazines and lectured worldwide in conferences on packaging, flexible packaging and converting equipment.