Advancing Curing/Drying Trends: A Pathway to Sustainable Bio-based Coating Solutions

- Published: August 28, 2023

By Albert John Tietz, Co-founder, Earthodic

In today’s dynamic industrial landscape, the pursuit of sustainable and eco-friendly solutions is a vital consideration for companies across various sectors as they attempt to reach both internal ESG (Environmental, Social and Governance) goals and geo-specific legislative pressure.

As the focus on reducing environmental impact and decarbonisation intensifies — particularly with focus on fossil-based plastics — the coatings industry is also witnessing significant advancements in curing/drying trends. These trends not only address traditional challenges of efficiency and productivity but also pave the way for the adoption of bio-based coatings processes.

Let’s explore the intersection of curing/drying trends and bio-based coatings, shedding light on their potential to shape a more sustainable future.

Evolving Landscape of Curing/Drying Trends

Curing and drying play crucial roles in the coating industry, affecting product quality, durability and overall performance.

Historically, conventional curing/ drying techniques relied heavily on high-energy consumption and the use of volatile organic compounds (VOCs), contributing to environ- mental concerns.

However, recent years have witnessed a shift toward more sustainable practices that improve both operational efficiency and environmental impact1.

Energy-Efficient Curing/Drying Techniques

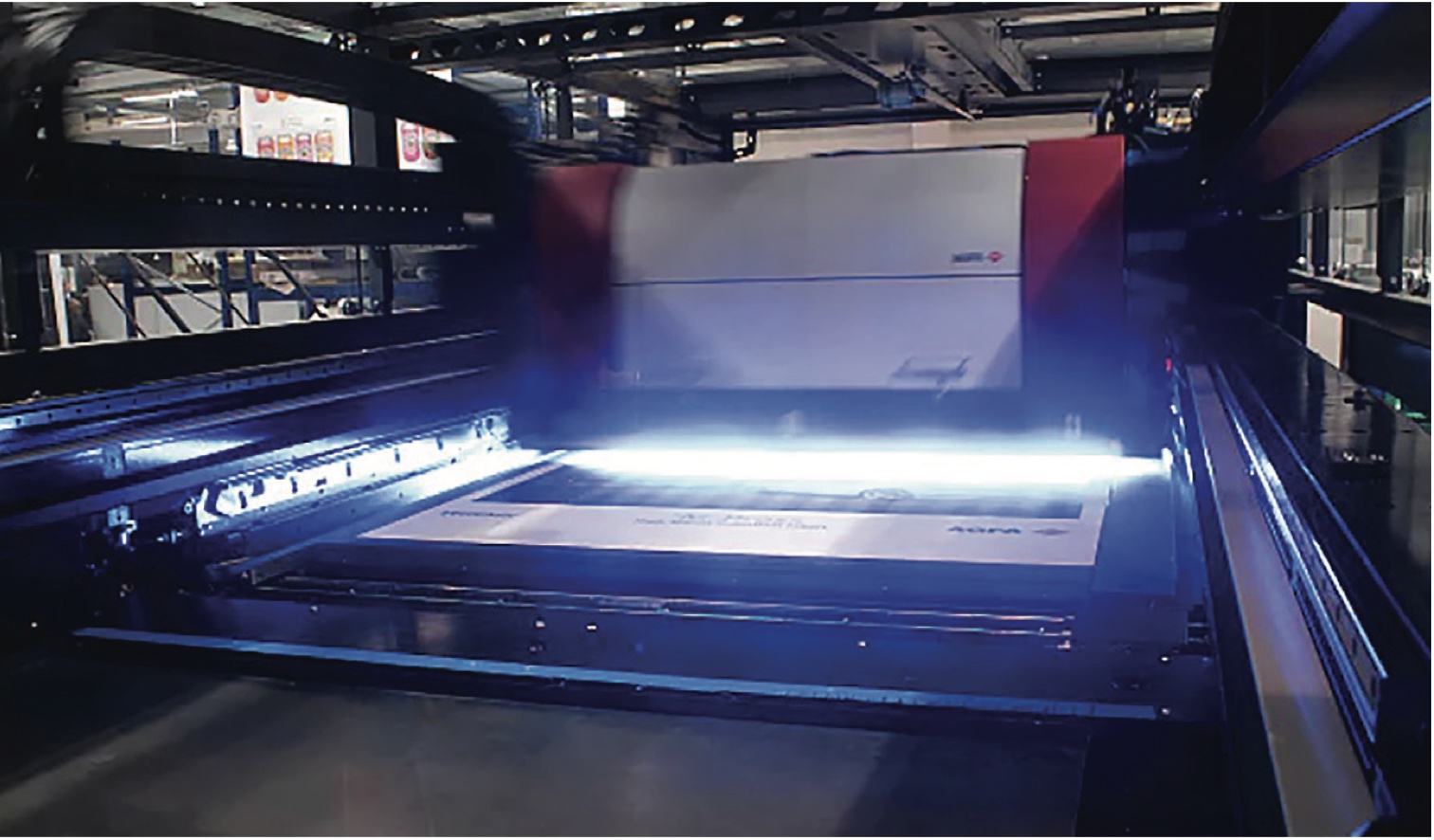

Innovative curing/drying technologies, such as infrared and ultraviolet (UV) radiation2, have gained traction due to their energy efficiency, reduced carbon footprint and ability to help power net zero climate goals3. For instance, the emergence of LED lamps has provided an opportunity to move away from more energy intensive mercury arc lamps4. These techniques significantly accelerate the curing/drying process, enhancing productivity while minimizing energy consumption and greenhouse gas emissions. Furthermore, they enable precise control over curing parameters, resulting in improved coating performance and reduced waste.

Waterborne Coatings

Waterborne coatings are emerging as sustainable alternatives to traditional solvent-based systems. Waterborne coatings, which use water as the primary solvent, significantly reduce VOC emissions and offer enhanced safety for workers and the environment5. Waterborne technologies promote resource conservation, while delivering excellent finish quality and durability.

Bio-Based Coatings: Pioneering Sustainability

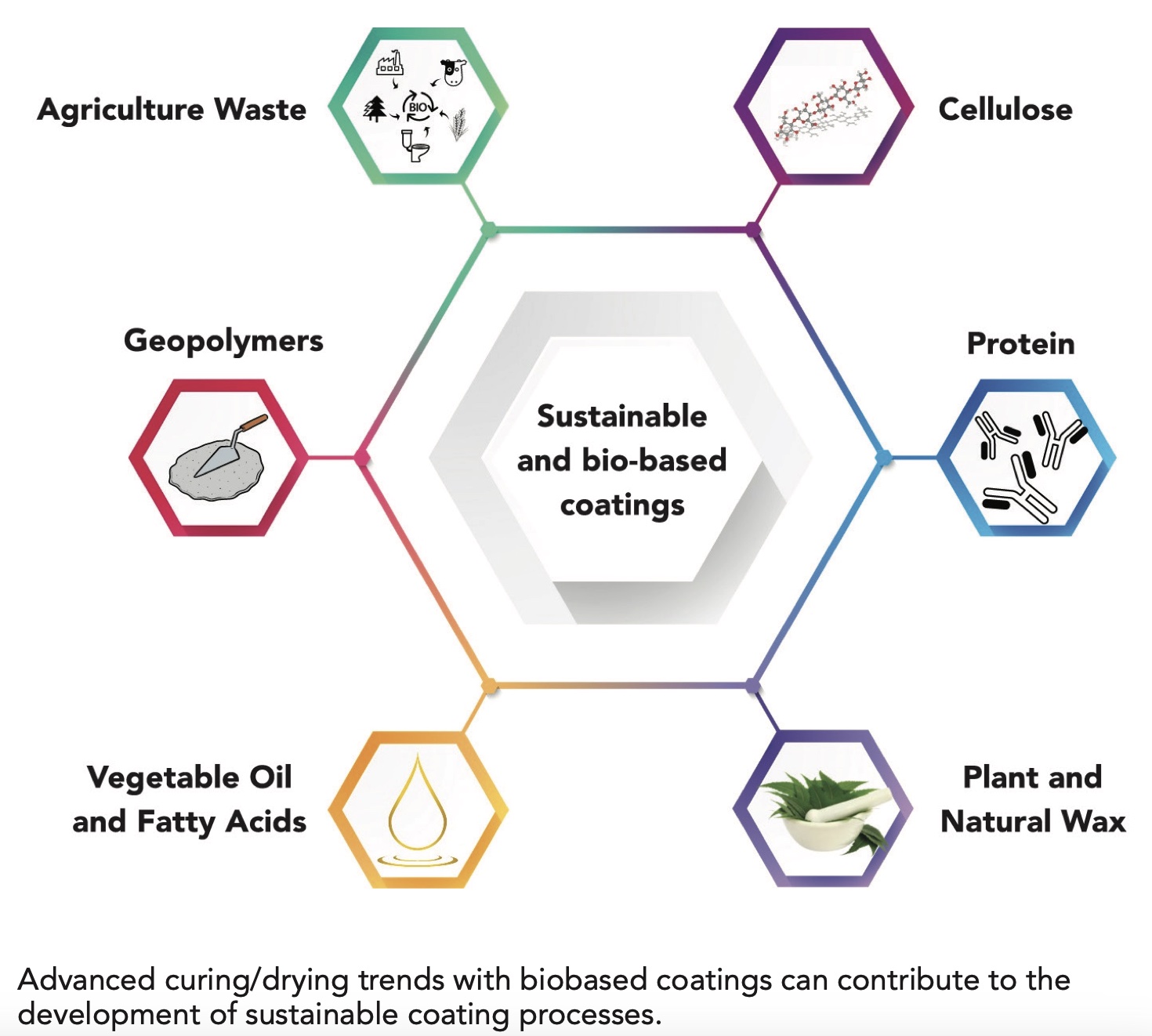

In conjunction with these curing/drying trends, the coatings industry is witnessing a remarkable surge in the development and adoption of bio-based coatings. These coatings leverage sustainable, renewable resources such as agriculture waste, cellulose, protein, geopolymers, plant-based oils, natural resins and biopolymers, offering a viable alternative to petroleum-derived raw materials6. Bio-based coatings not only reduce dependence on fossil fuels but also contribute to lower carbon emissions and environmental impact throughout their life cycle.

Benefits of Bio-Based Coatings

Bio-based coatings can exhibit comparable or superior performance characteristics to their conventional counterparts, ensuring long-term protection and aesthetic appeal. These coatings are inherently low in VOCs, minimizing emissions during the application and curing processes. Furthermore, their renewable nature and biodegradability make them more environmentally friendly, aligning with the principles of a circular economy. Coating materials of biobased nature can help support UN Sustainability Goals4.

The coatings industry is undergoing a transformative shift toward sustainability through advancements in curing/drying trends and the adoption of bio-based coatings. The integration of energy-efficient curing/drying techniques, such as infrared and UV radiation, has not only improved operational efficiency but also reduced energy consumption and greenhouse gas emissions.

Waterborne coatings offer sustainable alternatives to solvent-based systems, minimizing VOC emissions and promoting resource conservation. Furthermore, the rise of bio-based coatings, derived from renewable resources, addresses the need for environmentally friendly solutions, reducing dependence on fossil fuels and lowering carbon emissions throughout the product life cycle.

The benefits of bio-based coatings, including comparable or superior performance characteristics, low VOC emissions and their alignment with circular economy principles, make them an ideal choice for sustainable coating solutions.

Sources

- Sarfraz, M., Ozturk, I., Yoo, S. et al. Toward a new understanding of environmental and financial performance through corporate social responsibility, green innovation, and sustainable development. Humanit Soc Sci Commun 10, 297 (2023). https://doi.org/10.1057/s41599-023-01799-4

- Five major technology advances in UV curing you should know. January 1, 2018. Accessed June 26, 2023. https://www.fespa.com/en/news-media/features/five-major-technology-advances-in-uv-curing-you-should-know

- FIscher A. How Energy Efficiency Will Power Net Zero Climate Goals. IEA. March 29, 2021. Accessed June 26, 2023. https://www.iea.org/commentaries/how-energy-efficiency-will-power-net-zero-climate-goals

- Kennedy R. Four Ways Coating Material Support UN Sustainability Goals. Sepcial- Chem. December 10, 2021. Accessed June 26, 2023. https://coatings.specialchem.com/tech-library/article/coating-materials-support-united-nations-sustainability-goals

- SAFIC ALCAN. A greener future for coatings. Accessed June 26, 2023. https://www.safic-alcan.com/en/us/greener-future-coatings

- Sarcinella A, Frigione M. Sustainable and Bio-Based Coatings as Actual or Potential Treatments. Coatings. 2023; 13(1):44. https://doi.org/10.3390/coatings13010044

About the Author

Albert John Tietz, a dedicated researcher in sustainable coatings, co-founded Earthodic (www.earthodic.com) with a vision to transform the industry through environmentally conscious solutions. With extensive expertise in bio-based coatings processes, Tietz has spearheaded numerous research initiatives and collaborated with industry leaders to promote the adoption of sustainable practices.