AIMCAL Awards | Holographic Carton, Metallized Film Are Winners

- Published: March 23, 2018

The Assn. of Intl. Metallizers, Coaters & Laminators (AIMCAL) presented its 2018 Peter Rigney Product of the Year Award (named in honor of the former publisher of Paper, Film and Foil Converter and long-time champion of the competition, who passed away in 1997) on March 23 to Hazen Paper Co., Holyoke, MA, for its holographic carton for Kat Von D Metal Crush eye makeup. The awards ceremony took place at the group’s annual meeting, this year held at the DoubleTree South Park Hotel, Charlotte, NC.

KAT EYES

The Kat Von D Metal Crush highlighter palette carton features holographic Stardust metallized film laminated to the coated side of 0.020 solid bleached sulfate. The holographic film with the eye-catching pattern sets the stage for a printed, stamped and embossed surface and stands out on the department store shelf. The Stardust pattern with its pulverized metal appearance also reinforces the Metal Crush name.

The judges loved the rose-colored background and the impact of the design. “This carton has pizzazz,” noted one judge. “It really jumps out at you,” agreed another member of the panel. The judges also felt the package was well-executed. They concluded, “It brings a lot of elements together. It’s a beautiful use of holography and traditional printing.”

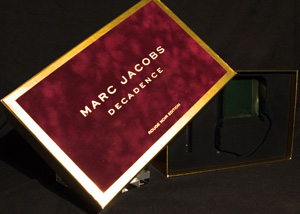

The judging panel also presented four Product Excellence Awards. Product of the Year winner Hazen Paper captured two, one for its role in a large setup box produced by WestRock/MPS, New York, NY, for Marc Jacobs Decadence perfume and one for the Porsche Music to Your Ears brochure for the Burmester 3D High-End Surround Sound System.

DECADENCE RULES

DECADENCE RULES

For the luxury perfume box, Hazen laminates film with a copyrighted embossing pattern to paper. The linen-embossed gold metallized polyester/paper laminate is applied to the box by WestRock/MPS, and a mottled-burgundy flocked fabric label completes the elegant package. The flocked fabric label provides a tactile experience as well as visual impact.

MUSICAL APPEAL

MUSICAL APPEAL

Visually, the Porsche Music to Your Ears brochure in a box appears to be a solid piece of aluminum, but it’s actually metallized film/11-point paperboard/metallized film, which marries Hazen Ultracure and Hazen 3DReflector CARD technologies. The laminate is ultraviolet-printable on both sides and feeds smoothly on the offset press. The result is an extremely flat, durable, water-resistant structure.

The judges noted two-side lamination is uncommon. “The printing is beautiful,” commented one member of the panel. “This is really classy and clearly unusual in terms of the combination of technologies used and in the potential for other applications such as paper-based gift cards.”

OVER THE TOP

Toray Plastics (America), North Kingstown, RI, earned a Product Excellence Award for its Torayfan Over-The-Mountain Portfolio of biaxially oriented polypropylene (OPP) films. Available in transparent, metallized or white and a variety of barrier levels, the film is designed to prevent packages from bursting when transported in changing altitude. A proprietary, modified PP core layer and a proprietary sealant work synergistically to improve hermetics and seal strengths. Compatible with virtually any pouch style, the films eliminate channel leaks and seal integrity problems caused by food residue in the seal area.

Toray Plastics (America), North Kingstown, RI, earned a Product Excellence Award for its Torayfan Over-The-Mountain Portfolio of biaxially oriented polypropylene (OPP) films. Available in transparent, metallized or white and a variety of barrier levels, the film is designed to prevent packages from bursting when transported in changing altitude. A proprietary, modified PP core layer and a proprietary sealant work synergistically to improve hermetics and seal strengths. Compatible with virtually any pouch style, the films eliminate channel leaks and seal integrity problems caused by food residue in the seal area.

The judges appreciated the value of thin-gauge film with the ability to seal well. “This structure definitely answers some of the problems commonly encountered with flexible packaging and seal integrity,” concluded the panel.

SPARKLING MOUTH FRESHENER

A Product Excellence Award also was bestowed on Flex Films (USA), Elizabethtown, KY, subs. of Uflex Ltd., Packaging Business, Noida, India, for a sparkling, tactile sachet with three-dimensional embossing for Shudh Plus Ultra mouth freshener. This package also received a Technical Excellence Award in the AIMCAL Technology of the Year competition (see below).

Glitter ink provides visual and tactile impact for the portion pack in a crowded retail environment. A specialized laser-engraved rotogravure cylinder with customized cell geometry traps the high-solid content of the glitter ink, which transfers to the substrate with the help of capillary action and the tangential force of the impression roller. The sachet relies on several other technologies. The base design is printed on coated paper using rotogravure and flexographic technologies. The printed substrate passes through an electron beam coating line in register to create the embossed effect on the brand name. Hot-foil stamping transfers the 3D embossed effect of the logo. To deter counterfeits the embossed effect is stamped in gold on one side and silver on the other, the first time different metals have been applied simultaneously.

Glitter ink provides visual and tactile impact for the portion pack in a crowded retail environment. A specialized laser-engraved rotogravure cylinder with customized cell geometry traps the high-solid content of the glitter ink, which transfers to the substrate with the help of capillary action and the tangential force of the impression roller. The sachet relies on several other technologies. The base design is printed on coated paper using rotogravure and flexographic technologies. The printed substrate passes through an electron beam coating line in register to create the embossed effect on the brand name. Hot-foil stamping transfers the 3D embossed effect of the logo. To deter counterfeits the embossed effect is stamped in gold on one side and silver on the other, the first time different metals have been applied simultaneously.

The judges were fascinated by what one described as a “small, but mighty” package. Members of the panel were impressed by the eye-catching power and sparkly texture of the glitter ink and the multiple embossed effects. “There’s a lot going on in this little package,” they concluded.

JUDGING PANEL The judging teleconference was moderated by AIMCAL Executive Director Craig Sheppard. The panel consisted of experts in converting and packaging: Tom Bezigian, principal consultant, PLC Technologies, Cicero, NY, and Poly Ploys columnist for Paper, Film & Foil Converter; Robert M. Kimmel, Sc.D., associate professor, director, Packaging Science Program, director, Ctr. for Flexible Packaging, Dept. of Food, Nutrition & Packaging Sciences, Clemson Univ., Clemson, SC; and Jeff Weber, former research principal Packaging Development at Mondelēz Intl., Deerfield, IL.

Technology Winner: Insulating Metallized Film for Shipper

Celplast Metallized Products, Toronto, ON, Canada, garnered kudos for its role in providing the metallized film the northbox insulated shipper, manufactured by Cascades Inc., Kingsey Falls, Québec, Canada. Recognized along with the Product of the Year, this additional award ceremony also took place at the group’s annual meeting at the DoubleTree South Park Hotel.

Celplast Metallized Products, Toronto, ON, Canada, garnered kudos for its role in providing the metallized film the northbox insulated shipper, manufactured by Cascades Inc., Kingsey Falls, Québec, Canada. Recognized along with the Product of the Year, this additional award ceremony also took place at the group’s annual meeting at the DoubleTree South Park Hotel.

The temperature-control box consists of a corrugated regular slotted container with two C-shape honeycomb paperboard/metallized film insulating liners. The first liner covers the bottom, top, and one side of the case, while the second liner nests within to cover the other three sides. The reflective property of the metallized film improves temperature control and also acts as a barrier to condensation, thereby preserving the pristine appearance of the paperboard. The insulated shippers can be specified Level 1 or Level 2 temperature control and have been laboratory tested under the ISTA 7E standard.

Considered more sustainable than traditional foam-based insulating panels or bubble wrap, the honeycomb paperboard and corrugated box contains 100% recycled fiber content and may be recycled curbside because the metallized film easily separates from the honeycomb paperboard during the recycling process. Applications include ready-to-cook/eat meal kits; live products such as lobsters, worms or plants; specialty meats/cheeses; online grocery orders; pharmaceuticals, blood and vaccines.

The judges liked the sustainable aspects of the patent-pending design and its potential impact in the marketplace given the rapidly growing use of e-commerce by consumers. “This design definitely reduces waste versus existing temperature-control shippers,” commented one judge. “It’s a breakthrough replacement for other materials that are less sustainable,” noted another. “It’s a product everyone can relate to,” the panel concluded.

Two Receive Technical Excellence Awards

The judges also awarded two Technical Excellence Awards. One Technical Excellence Award was presented in the Coated, Laminated or Metallized Product Category and went to Flex Films (USA) Inc., subs. of Uflex Ltd., Packaging Business for a sparkling, tactile sachet with three-dimensional embossing for Shudh Plus Ultra mouth freshener. This package also received a Product Excellence Award in the AIMCAL Product of the Year competition. (See winning attributes above for the Sparkling Mouth Freshener Technical Excellence entry.)

The judges also awarded two Technical Excellence Awards. One Technical Excellence Award was presented in the Coated, Laminated or Metallized Product Category and went to Flex Films (USA) Inc., subs. of Uflex Ltd., Packaging Business for a sparkling, tactile sachet with three-dimensional embossing for Shudh Plus Ultra mouth freshener. This package also received a Product Excellence Award in the AIMCAL Product of the Year competition. (See winning attributes above for the Sparkling Mouth Freshener Technical Excellence entry.)

The judging panel was impressed by the combination of technologies used to maximize shelf impact for this small sachet as well as by its renewable, paper-based substrate. “It’s a deceptively simple package, but there’s a lot going on, and it’s very well executed,” noted one judge.

The other Technical Excellence Award was presented in the Material Category and went to the Dow Chemical Co., Packaging & Specialty Plastics, Lake Jackson, TX, for its Adcote HP laminating adhesive. The greener adhesive contains no bisphenol-A (BPA), BPA epoxy or ortho-phthalic acid-based polyester. It’s FDA 177.1395 acceptable Condition B through H (all food types) and registers a primary aromatic amines level of less than 2 parts per billion after a two-day cure at room temperature. It adheres strongly to polyester, polyethylene, cast and oriented polypropylene and oriented polyamide film and foil, withstands aggressive foods/chemicals and harsh application conditions.

The other Technical Excellence Award was presented in the Material Category and went to the Dow Chemical Co., Packaging & Specialty Plastics, Lake Jackson, TX, for its Adcote HP laminating adhesive. The greener adhesive contains no bisphenol-A (BPA), BPA epoxy or ortho-phthalic acid-based polyester. It’s FDA 177.1395 acceptable Condition B through H (all food types) and registers a primary aromatic amines level of less than 2 parts per billion after a two-day cure at room temperature. It adheres strongly to polyester, polyethylene, cast and oriented polypropylene and oriented polyamide film and foil, withstands aggressive foods/chemicals and harsh application conditions.

The judges recognized the essential role adhesive plays in successful laminations. “This material is a step forward,” stated one judge. “It will make laminate structures better products,” concluded another member of the panel.

The judging teleconference was moderated by AIMCAL Executive Director Craig Sheppard. The panel consisted of recognized experts in the converting field: Dr. Charles A. Bishop of C.A. Bishop Consulting, Loughborough, U.K.; Dr. Edward D. Cohen of Edward D. Cohen Consulting, Fountain Hills, AZ; and Dr. Eldridge M. Mount of EMMOUNT Technologies, Canandaigua, NY.

For more information, contact AIMCAL.