Coating Matters | Pump Technology

- Published: January 13, 2015, By By Mark Miller and Jim Feltman

If you'd like to hear from Mark Miller's own lips rather than read his column, titled "Coating Matters | Pump Technology," click on his podcast below:

{mp3}pump-technology{/mp3}

Fluid preparation and delivery may be ancillary to the coating process, but they are critical to the coating outcome.

![]() Fluid coating is dependent on five main factors to have the precision required for today’s coated products:

Fluid coating is dependent on five main factors to have the precision required for today’s coated products:

- Coating head

- Positioning system for the coating head

- Substrate uniformity

- Backing roll tolerance

- Fluid delivery system

The fluid delivery system is a broad definition of the equipment that mixes, filters, measures, and delivers the functional fluid to the coating head. If the fluid delivery system is not a precise and accurate tool, then the coating will fail to perform regardless of the manufacturing tolerances and specifications of the other factors involved.

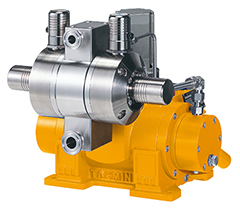

The fluid delivery system may have multiple parts that work in concert to provide fluid precisely, but the heart of the fluid delivery system is the pump. When it comes to fluid delivery systems, typically there has been a standard go-to set of pumps that are considered for precision metering: gear pumps, progressive cavity pumps, and pressure pots.

In the past, I never would have considered a diaphragm pump for precision coating applications. When you think of a diaphragm pump, you think of pulsation. However, some modern diaphragm pumps are fluid delivery systems within themselves. Improved designs have led to engineered combinations of chamber design, check valves, fluid routing, and cam profiling that provide accurate output with reduced pulsation.

In the past, I never would have considered a diaphragm pump for precision coating applications. When you think of a diaphragm pump, you think of pulsation. However, some modern diaphragm pumps are fluid delivery systems within themselves. Improved designs have led to engineered combinations of chamber design, check valves, fluid routing, and cam profiling that provide accurate output with reduced pulsation.

Why is it critical to consider the pump technology? Air. Air is consistently the main cause associated with coating defects. Removing air from the system is paramount, and making sure that air is not introduced prior to coating is critical. The key is consistently smooth flow. Pumps can be affected by pressure changes on the discharge side of the system, and a good pump will be able to demonstrate steady state flow. It is also critical that if there are seals, air is not introduced at these locations. For some critical coating systems, a pressure balance is measured on both sides of every seal point. If a pump can reduce the number of seals involved, air will be less of an issue.

Why won’t one pump work for every application? This is a complex answer, but one simple response is that not all fluids are compatible with pump technology or materials. As examples, shear sensitive materials perform poorly with a gear pump, and some solvents may swell the rotor or stator in a progressive cavity pump, and solid particles in suspension may damage internal parts of a pump that they come in contact with. When considering the pump technology, remember to look at the critical factors of the fluid (solids content, solids size, shear effect, viscosity, and solvents). A good pump vendor can provide guidance for this selection.

Fluid preparation and delivery may be ancillary to the coating process, but they are critical to the coating outcome. The fluid delivery system provides a consistent flow of material to the coating head for proper pressurization and distribution crossweb. In addition, the fluid delivery system and the line speed control of a roll-to-roll coating line are the two factors that determine downweb distribution of a fluid coating onto a substrate.

When it comes to pumping, filtering, and de-gassing of coating fluids for the converting industry, as much care has to be taken as in the development, design, and implementation of the coating head technology. When searching for systems solutions for your coating application, make sure you do not overlook the fluid delivery system and the capabilities provided by the pump technology. There are reasons to consider all types of pumps for given coating applications, and I would make sure to consider (and evaluate) multiple types for your application.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

James Feltman is VP of TACMINA USA, Schaumburg, IL, and a 30-year veteran of high-tech manufacturing. He is also a trained lean manufacturing expert and has worked for companies such as Toyota, Boeing, GE, Pfizer, BASF and many more. Jim is a dedicated technical enthusiast who is constantly studying topics such as fluid dynamics, rheology, and advanced manufacturing techniques. A mechanical engineer with a specialty in process automation, Jim combines his lean manufacturing training, experience, and new discoveries to develop unique solutions for his customers. Jim lives in Chicago with his wife and three children. In his spare time, he plays guitar in an 80’s hair metal band although he has little hair to speak of these days. He can be reached at jim_feltman@tacmina.com.

James Feltman is VP of TACMINA USA, Schaumburg, IL, and a 30-year veteran of high-tech manufacturing. He is also a trained lean manufacturing expert and has worked for companies such as Toyota, Boeing, GE, Pfizer, BASF and many more. Jim is a dedicated technical enthusiast who is constantly studying topics such as fluid dynamics, rheology, and advanced manufacturing techniques. A mechanical engineer with a specialty in process automation, Jim combines his lean manufacturing training, experience, and new discoveries to develop unique solutions for his customers. Jim lives in Chicago with his wife and three children. In his spare time, he plays guitar in an 80’s hair metal band although he has little hair to speak of these days. He can be reached at jim_feltman@tacmina.com.