Folding Carton Shows Off

- Published: February 28, 2007, By John D. Brown, Light Impressions Intl. Ltd.

Web Exclusive

Few packaging technologists would deny that when it comes to new product introductions, flexible packaging in the form of plastic films increasingly has been chosen over more rigid materials such as the folding paperboard carton and its first cousin, the corrugated container. The reasons for this have been largely cost related. Plastic films provide significant material source benefits, they reduce material cost through weight reduction, and occupy less landfill space at the end of the product’s life cycle.

A counter argument is that paperboard cartons and corrugated media are made from sustainable natural materials and are recyclable. Indeed, in consumer polls carried out in countries such as France, cartons/corrugated are preferred over film and are perceived as being more environmentally friendly than film.

While it’s true that folding cartons as a packaging format have taken a direct marketing hit from flexible film pouches in the areas of wet and dry pet food, agro/chemical products, certain dry mixes, and eat-on-the-go product categories, cartons are far from being on the ropes, the benefits cartons provide cannot be ignored.

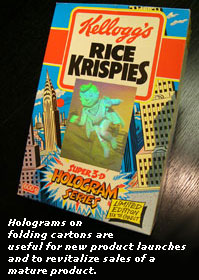

Take pet food pouches for example. These flexible package items very rarely stand alone on the retail shelf; they are packed, transported, and stacked in cartons on the retail shelf. The reason: Not only do rigid and relatively lightweight cartons prevent product damage, the surface of these materials provides enormous billboarding opportunities. Graphics and printing on cartons are bold and vibrant, while the construction allows for enhanced visual effects to be added, such as embossing, foil stamping, and holograms.

Boosting and sustaining profitability are critical to the long-term health of the paperboard market. While manufacturers are offering newer material configurations that provide strength and durability and a surface receptive to decorative processes, success in the retail environment—the ability to attract consumers—depends on the packaging designer’s use of color and other eye-catching elements and on the converters ability to translate that vision into hard fact.

Packaging graphics are important for many reasons, including the psychological and perceptual consequences of viewing them. In this context the role of color and shape, lighting conditions, and surrounding objects in the field of view influence interpretation and appreciation of what is seen.

Adding a special effect to a package is one of the best ways to get a new brand noticed among dozens of similar products and thousands of other items on the retail shelf. By inviting a second glance, that special effect can extend the period that the consumer looks at the product.

One sure fire way to obtain a “look-at-me” look is via holographic technologies offering geometric, shimmering, and reflective metallic effects that provide the consumer with an almost interactive experience. Quite unlike any other decorative medium, the diffractive nature of holograms—the ability to incorporate all manner of designs within the surface—simply invites attention. Few can resist handling a product that contains a holographic design element or security feature, and this in itself reinforces the “must-have” desire and aids in the shifting of goods from the shelf and into the shopping trolley or basket.

The brilliance of holograms appeals to some form of primitive magpie element in our psyche; they have a retentive value, and holograms are not only useful for new product launches, they help revitalize sales of a mature product and are useful in highlighting coupons, change of ingredients, competitions, and other promotional incentives.

There are several types of holograms. A reflection hologram, for example, is viewed when lit from the front. A transmission hologram, on the other hand, is viewed by shining light through it from the reverse side. An embossed hologram—the type typically associated with packaging applications—is made by backing a transmission type with a mirror reflecting substance that allows it to be viewed when light strikes the front of the package or other material surface.

Holograms can be produced in the form of patterned foils, as 2-D images where all the information is contained on a single plane, as 2-D/3-D images whereby even flat artwork or a photographic subject can be made to take on the appearance of 3-dimensional characteristics, or with planes appearing to float at different depths within the image. Alternatively, true 3-D imagery or effects can be created, providing the illusion of looking around an object, one that may seem to rotate or float in space according to changing angles of view.

True 3-D imagery, that is the so-called classically produced hologram, is available also. This method of hologram production involves the skill of a craftsman holographer in creating a master image from a model or other subject using specialized equipment. Not only does this method of production create the most visually stunning of all the holographic methods, it provides the highest level of security in anti-counterfeiting applications in that the hologram itself cannot be copied. A counterfeiter would need access to the original master, expensive equipment, and craftsman skills.

SUPPLIER INFO:

Light Impressions Intl. Ltd.—lightimpressions.com

John D. Brown is chairman of Light Impressions Intl. Ltd., Leatherhead, Surrey, UK. Light Impressions Intl., a founding member of the Intl. Hologram Mfrs. Assn., currently protects and/or enhances the appearance of more than a billion items annually with a range of optical variable holographic solutions.