Reducing Surface Contamination

- Published: March 16, 2015, By Tom Bezigian

Whether the process being used is blown film, cast film, cast sheet, extrusion coating, extrusion lamination, adhesive coating, or adhesive laminating... all processes are subject to airborne contamination either in or on the finished product. When the finished product is optical, graphics, electronic, or retail, visual defects are not allowed, either for technical reasons, or for aesthetic reasons. This article will look at some strategies to eliminate contamination, both from an electric viewpoint, and an overall prevention viewpoint.

When I owned Great Lakes Technologies LLC, we produced several products which involved extrusion coating onto oriented polyester films. Some of these products had critical optics requirements, and had to be free of optical defects, both on the film, and within the film. We used HEPA filters on all resin conveying lines, and various web cleaning techniques to clean the surface of the film.

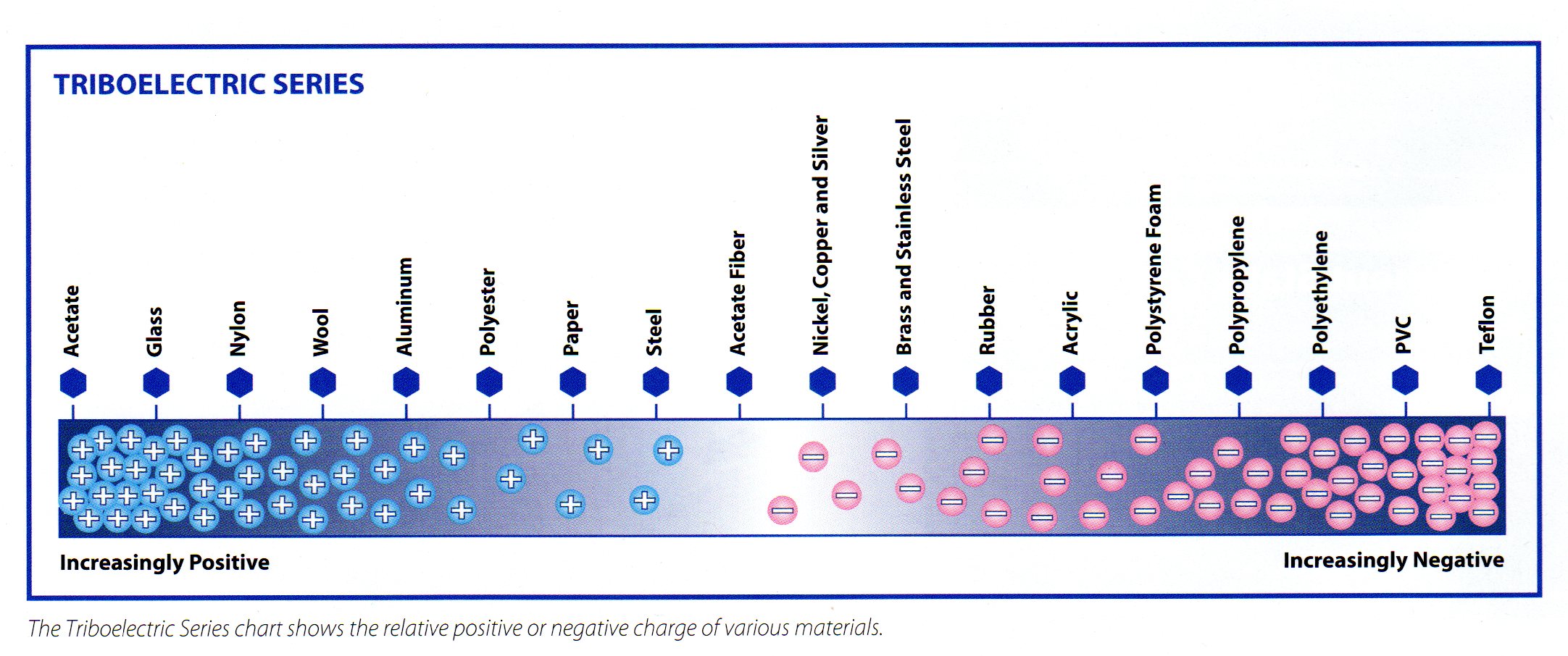

Probably the worst of all the products we made back then was a fluoropolymer/acrylic blend extrusion coated onto a heavy gauge oriented polyester film. If you look at the chart below, it is easy to see that polyester is on one end of the electronegative scale (electron donor) and Teflon® (fluoropolymer) / acrylic is on the other end of the scale (electron receivers). In fact, fluorine is the most electronegative of all elements, which explains some of the excellent chemical and temperature resistant properties of Teflon®.

(Chart from Simco-Ion Industrial Products Catalog, 5200522, Rev. J, p 2)

The greater the distance apart from each other in this chart, the greater the tendency to transfer electrons between surfaces, and thus the greater the static charge.

I suppose it can be said that static charge, in and of itself, is not important, if... and that is a BIG IF... 1) there are no people nearby to receive the static charge built up in the non-conductive materials, and 2) there is no airborne contamination to be attracted to the static charge. Typically however, these two conditions are never met. People are always in the vicinity of the wound-up product, and unless in a clean room, there is always airborne contamination nearby. In fact, household dust has been documented to contain 5,000,000 particles of dust per cubic meter. Typical factory air contains more airborne contamination, if for no other reason that the proliferation of corrugated board in the plant. In addition to the discomfort caused by shocks due to static discharge, they are inherently unsafe. While the discharge itself may not harm a worker, it may cause the worker to slip, fall, or move suddenly, which in turn may cause an accident.

Quite often, entrapped corrugated fiber is mistaken to be a "gel". To the naked eye, this is easy to understand, as they visually appear the same from a distance. The fibers diffract light so as to look like a gel, which in some cases can be considered quality defects. Gels of course, are ultra-high molecular weight compounds that do not melt, yet go through screen packs, and manifest themselves as optical defects that refract light.

One thing I did when designing and installing the line was to elevate it a foot (30 cm) off the ground, as can be seen in the photo below. The mere addition of distance from a contamination source greatly reduces electric attraction. Also visible in the this photo is a grounding point. The line contained about 30 such grounding rods in a effort to minimize static buildup.

Photo by Tom Bezigian

The grounding of the machine had limited effectiveness on neutralizing the static charge in/on the web. Plastic, being the insulator that it is, does not readily give up its charge, and if it is a "positive" material like PET, it really isn't effective at all. So, in addition to grounding, we used static eliminators at critical point in the process, which are typically before priming, coating, and winding. The next photo shows a SIMCO static removal bar just prior to the extrusion laminating station. The blue rolls seen are "tacky" rolls, which also remove surface contamination. The units today are much more sophisticated, but this illustrates the point of static elimination and web cleaning. Another station identical to this one was installed just prior to the winder.

Photo by Tom Bezigian

Lastly, while not a "clean room" per se, it was a relatively clean room, as shown in the photo below. As can be seen in the photo, the floors were epoxy sealed, but what you can't see is important too. The make-up air entering the room passed through a class 100,000 HEPA filter, and the entry ways sealed with high-speed, rolling flexible doors, and all doorways had double-sided "sticky tape" to clean the bottom of shoes, and all cardboard was kept outside the room. Every effort was made to minimize airborne contamination, including the use of electric fork-lift trucks.

In the end, the product made passed the scrutiny of major corporations for cleanliness, and these measures were effective. These additions probably cost $250,000 at the time, but is the cost of entry into the world of cleanliness.

Special thanks to Mike Bartle of Empire Tech Solutions/Simco-Ion for his time and providing graphics for this article. He can be reached at mike@empire-tech.net or +1 585-924-8980.