Nordmeccanica SpA a Laminating Powerhouse

- Published: May 21, 2013, By Tom Bezigian

While in Italy in May, 2013, I had a nice chat with Giancarlo Caimmi, Commercial Director at Nordmeccanica Spa, in Milan. We discussed their product lines, processes employed, products made by their customers, and much more. I found it fascinating in many ways, but perhaps the most fascinating is their approach to business.

I guess the short story is that Nordmeccanica makes every type of roll to roll laminator except for extrusion lamination. This includes wet bond and dry bond adhesive systems requiring a dryer as well as solventless laminators. As far as oven drying systems, the produce all types ovens with the exception of air flotation dryers. Their equipment can handle paper, film, foil and non-woven substrates from a variety of applications, such as flexible packaging, pharmaceutical packaging, security products, tamper evident products, window films, thermal insulation and bullet-proof products.

The best place to start is that Nordmeccanica’s philosophy is standardization… something the Italians call “Integration”. They do not make one-of-a-kind, custom machines, which I found quite interesting. The industry has standardized on certain widths, and certain coating methods, and of course, certain product constructions. Once a customer specifies the list of materials to be laminated, and the performance requirements, they set out to build the machine.

According to Caimmi, coating heads are standardized and modular, and can be switched out very quickly for example from rotogravure to slot die. Parts are standardized using the best quality available, such as Siemens electronics. The two components that they do not specify, or rather, allow the customer to specify are heating and cooling systems which are sourced locally to get the best service possible, and corona treaters.

Nordmeccanica is such a large producer and commands such a large portion of the market that they act almost as the Wal-Mart of the converting industry, ordering thousands of idler rolls, motors, blowers, etc. and once. This allows them to produce an excellent quality product with good turn-around times at a very competitive price, something I call the “Quality-Service-Price” continuum. Typically, in the long run, a supplier can only provide two of these three attributes, while the third must suffer. With their strategy of standardization, they are able to offer all three to their customers, which might explain why they own nearly 100% of the flexible packaging market (except for one major player in the USA) and about 2/3 of the coating & laminating market (ex-extrusion coating) worldwide.

Apparently they have many happy customers around the world who are willing to share the fact that they own Nordmeccanica equipment, such as Ashland, Bostik, Coim-Novacoat, Dow, H.B. Fuller, and Henkel. All of these companies offer their equipment for pilot work, at widths between 17”-55” (43-140 cm) and speed of 150-200 meters/minute.

A recent addition to the Nordmeccanica product line is Galileo metallizers. Nordmeccanica is building a separate 60,000 square foot (5750 square meters) facility to house the new company, which will be called Nordmeccanica Vacuum. I expect that product line to be standardized soon also.

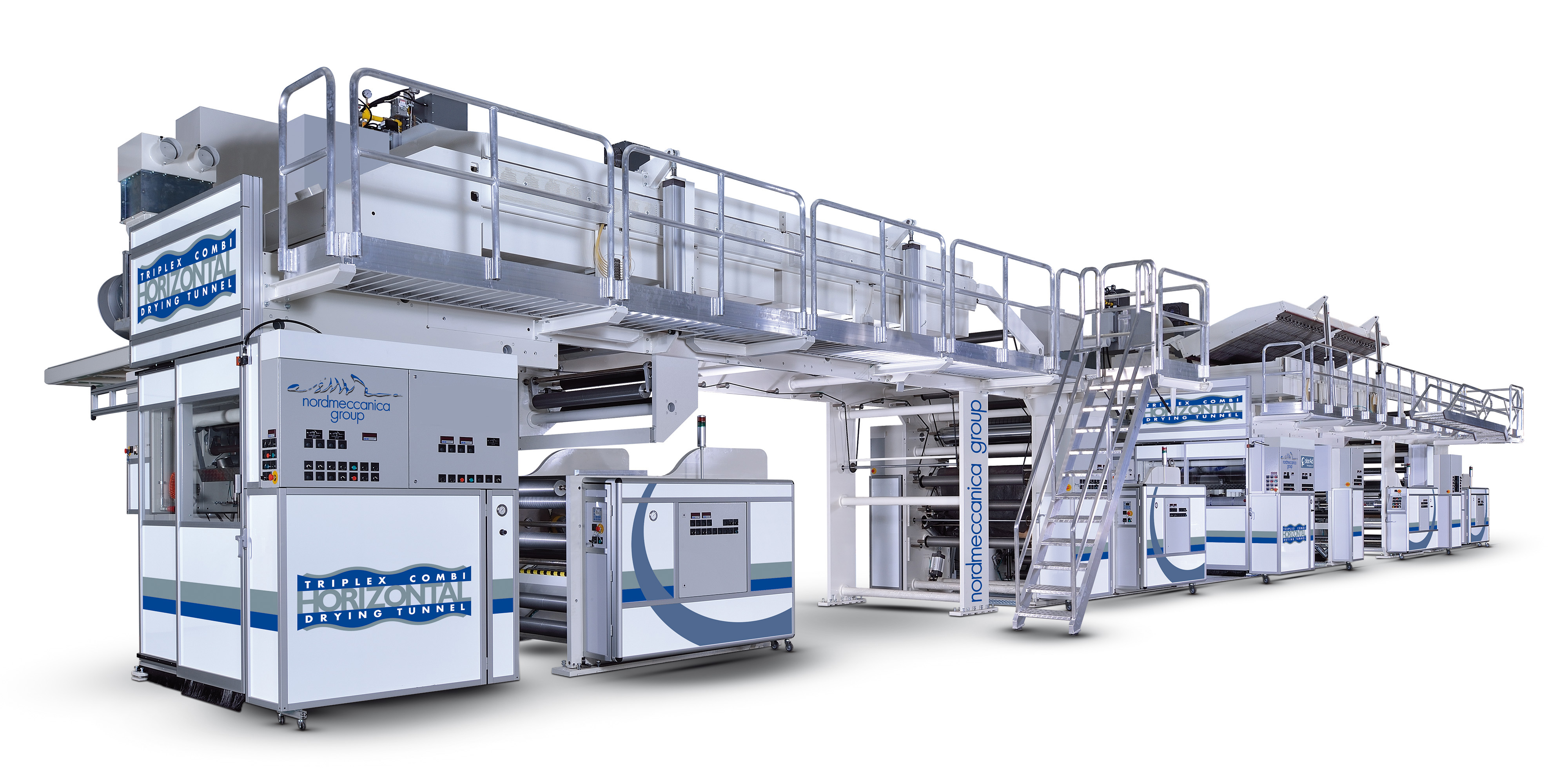

I've attached a few photos below for reference. At this time, Nordmeccanica has about 35 machines on the floor, and they make nearly 200 per year, far more than any other machine supplier that I am familiar with. This is a comforting thought in that a profitable company is likely to be around in the future to service your needs.

The last tidbit I'll offer... Milan Centrale is 3 hours by high speed train from Roma Termini. You then need to connect to a train going to Piacenza to visit Nordmeccanica. Count on at least 4 hours to make this trip. Use http://www.trenitalia.com/cms/v/index.jsp?vgnextoid=ad1ce14114bc9110VgnVCM10000080a3e90aRCRD to mae your reservations.

For further information, visit Nordmeccanica at the K-Show in Düsseldorf in October or their website http://www.nordmeccanica.com/en/index.php or call:

Giancarlo Caimmi, Commercial Director

Nordmeccanica Spa,

Strada dell’Orsina, 16 - 29122 Piacenza - Italy

Tel. 0039 0523 596411 - Fax. 0039 0523 612051

e.mail: caimmi@nordmeccanica.com

+1 631 242 9898 (usa)