Sustainability Within Bags, Pouches and Emerging Films

- Published: December 25, 2022

By Mike Greely, Senior Vice President Totani America

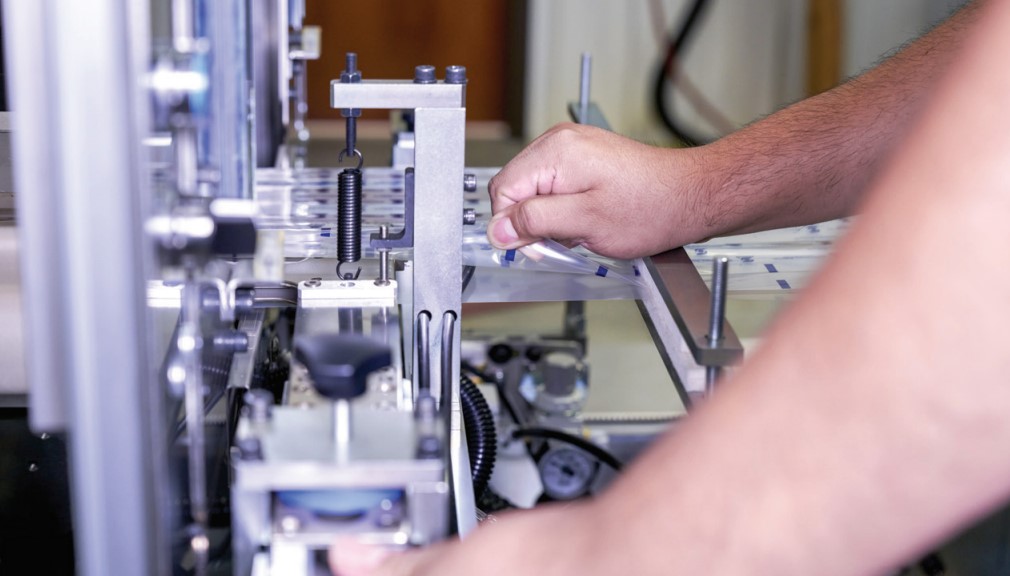

From production and functionality to sustainability attributes, bags and pouches need to provide an optimal experience for both the customer and consumer. As sustainability continues to be the most dominant topic within the flexible packaging industry, bag- and pouch-making machines continue to be optimized to handle and facilitate sustainable packaging materials.

As manufacturing partners support the transition to new, sustainable flexible films, there are a variety of opportunities for these bags and pouches to deliver excellent machinability with ever-emerging innovations in engineered films. In this article, we take a closer look into the current state of the packaging industry, as well as how collaborative partnerships will help transform the ongoing sustainability movement.

Challenges with Sustainable Packaging

A common challenge in the packaging industry is determining the most effective way to incorporate sustainable films into existing packaging machines. For instance, when a packaging company needs to make a recyclable pouch, they need to identify how those materials will run and what impact the process will have on their operations. Although printers/converters want their packaging machines to run these sustainable films, they are more difficult to run than standard films due to their lack of heat resistance.

An important component to consider during the production process is making a quality seal. The amount of heat required to seal, and not stretch the film, is critical for making a successful pouch. In addition, bags and pouches for particular markets need barrier properties, such as those used for packaging pet food, lawn and garden products, and grocery store items. Creating sustainable packaging for these types of products is even more challenging due to their protection throughout the supply chain prior to consumer use.

Equipment manufacturers are actively engaged in finding solutions and opportunities for working with new film structures. They are going above and beyond to create strategic partnerships within the industry related to sustainable packaging, as well as learn about the films and how they interact with machines.

Sustainable Materials and Packaging Structures

Overall, while flexible packaging has a far smaller carbon footprint than other types of containers, sustainable solutions will help customers meet the market demand for more sustainable products.

Over the last several years, sustainable films and materials have improved drastically. For example, machine-directed orientation (MDO) films are used for their resistance to stretching in the film flow direction of the machine film. Utilizing various types of films and materials can help produce a better product, ultimately aiding in the consumer experience.

With sustainable packaging, converters and CPGs are tasked with determining if the structure needs to be adapted to a machine or if it’s suitable as is. This decision is also dependent on how the customer is using the structure and if it’s easier to process on a pouch machine. The question needs to be answered: How can we produce a sustainable package with the same seal integrity, low scrap rate and high production speed, as we can with traditional films?

There have also been adaptations to pouch machines to accommodate sustainable films. For instance, ultrasonic sealers have been used to help crush the zipper profile in the seal area, where in the past heat seals were normally used. In addition, improvements to the way film is drawn and registered in the machine has drastically helped counter the effects of film stretching and print repeat variation.

The Future of Sustainable Flexible Packaging

The flexible packaging industry has a variety of sustainable opportunities, from the materials and films used to the machines’ engineering. An important aspect of creating these opportunities is to evaluate what can be done with the materials we are working with now, such as enhancing efficiency and ease of operation, achieving faster runs and decreasing scrap levels. CPGs, printers and converters tend to lead these internal efforts, and they continuously push the industry to collaborate and develop solutions for a more sustainable future.

To achieve these sustainability goals, manufacturing partners can work together to create and apply sustainable solutions for their customers. For converters, it’s important to find and implement a pouch machine — sooner rather than later — that accommodates both non-sustainable and sustainable materials to be ready at a moment’s notice. Companies can be proactive by adapting their operations to be more sustainable, instead of reacting to the increasing consumer demand and potential future regulations.

Converting machines can be optimized for handling sustainable packaging materials, and manufacturing partners can support the transition to new, sustainable flexible films. Even with the present challenges, there are opportunities to be prepared for different packaging equipment and configurations.

About the Author

Mike Greely, senior vice president for Totani America, a manufacturer of pouch making machines for flexible packaging. Founded in 1952 — celebrating its 70-year anniversary — Totani machines are being used in more than 60 countries. Visit the Totani website and contact pages to learn more about the company’s products, services and expertise.