Are You Rough Enough?

- Published: January 31, 2006, By Timothy J. Walker, TJWalker & Assoc. Inc.

Web Lines

Rough necks, rough language, rough drafts, and golf balls in the rough. Smooth operator, smooth as a baby’s bottom, smooth sailing, and smooth moves. Smooth gets all the good press. Rarely is rough an admirable quality.

What is the better roller surface to prevent web scratching, smooth or rough? Many people will opt for smooth, but in fact, this is the wrong direction.

If we want to scratch something or “rough it up,” we grab something that has high roughness (and usually hardness, too). We know if we push the hard, rough object against the to-be-scratched object and work the surfaces back and forth against each other, the soft material will begin to wear down.

This is all true, but roughness is a secondary factor. Abrasive wear occurs anytime you push two materials together and slide them relative to each other. Whether smooth or rough, you’ll get scratching.

In web-roller contact, the key to eliminating scratches is to prevent the relative motion. Keep the roller surface turning at web speed. You can lie down on a bed of nails and you won’t scratch yourself—just don’t slide on it.

Why are rougher surfaces better at eliminating scratches? Roughness prevents traction loss from air lubrication. As long as the combination of tension, wrap angle, and traction coefficient can apply enough torque to overcome roller drag and inertial torque—no scratches. But as you want to run faster, with lower tension, or with larger radius, you will be more prone to air lubrication.

A simplified model of air lubrication (from work at the Oklahoma State Univ. Web Handling Research Center) says the lubrication of a surface begins when the entrained air layer height is equal to the combined roughness of the web and roller surfaces and reaches full lubrication (zero traction) when the air layer is triple this height.

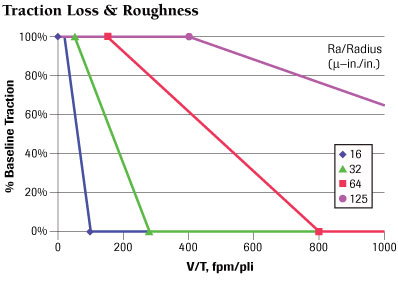

Increasing roller roughness can prevent traction loss at increasing web speed to tension ratios. Since air layer goes up direct with radius, you need more roughness for larger rollers. The curves on this graph include this by plotting traction losses as a function of Ra to radius ratio.

If you run 300 fpm at 1 pli tension, an Ra of 32 micro-inches/in. of roller radius would be fully lubricated, but an Ra of 64/in. of radius would only have lost about 20% of its initial traction. A 4-in.-dia roller may be fully lubricated if the Ra was only 64 but likely will still have good traction with an Ra of 125.

These traction loss curves are conservative with no consideration of web roughness, edge effects, web porosity, or uneven tension across the web, but it’s clear that a little roughness shouldn’t rub you the wrong way.

Next month: More on roller surface options.

Timothy J. Walker has 20+ years of experience in web handling processes. He specializes in web handling education, process development, and production problem solving. Contact him at 651/686-5400; jwalker@tjwa.com; tjwa.com.