Measure Static in Wound Rolls

- Published: November 15, 2021

Audit static on finished rolls and on incoming materials to prevent problems.

By Kelly Robinson, PE, PhD, Electrostatic Answers

Controlling static is important for at least three reasons:

- Safety – Low static prevents sparks that shock operators and ignite fires;

- Quality – Low static also prevents product damage and dissatisfied customers; and

- Productivity – High static causes production jams and downtime.

Hearing from a dissatisfied customer about a static problem with your product is often a surprise because static seems to be under control in our operations. How can we make sure that static levels in our finished goods satisfies our customers?

Measure static on finished, wound rolls. While this sounds simple, we need to take an extra step to remove the out lap of web from the roll. This is how we can take static readings to learn about static stored in the roll.

The web wound into finished rolls can be many thousands of linear feet. Even if there is just a little bit of static per square foot on the web, the winding roll stores all of this static. Just a little bit of static on thousands of linear feet of web can be enough to cause problems.

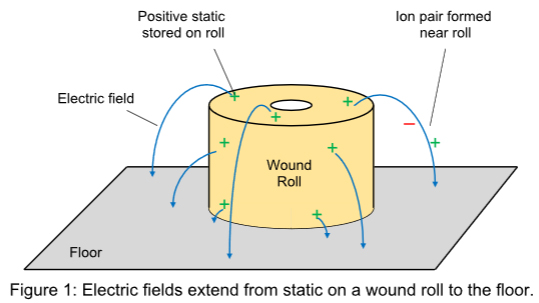

How do we measure static stored in the wound roll? To see why we need to remove the outer lap of web, look at the wound roll in Figure 1 sitting on the floor. The static stored in the wound roll cause electric field that extend to the floor. Even though the floor surface may be insulating, the concrete subfloor is typically conducting.

We can use our handheld static meter to measure the electric fields near the surface of the wound roll. I find that these fields decrease with time, sometimes in just a few minutes. It is easy to think that static is dissipating from the wound roll. However, the static charges stored in the wound roll persist.

When we measure the fields near the surface of the wound roll, we measure the static charges stored inside the roll and static charges that accumulate on the outer surface of the roll. The ion pair in Figure 1 is formed by cosmic rays and by background radiation, such as radon gas. In fact, the air in the factory and in our homes always has a small number of ions formed by these naturally occurring ionizing sources. And, the number of ions varies widely. At higher altitudes where there is also high air exchange from outside the building, ion pairs formed by cosmic rays are higher. In regions where background radiation is higher, more ion pairs are formed inside buildings.

Ion pairs formed near the wound roll causes the measured fields to decrease with time. The positive static stored on the wound roll in Figure 1 attracts the negative ion in the air. This ion moves through the air and deposits on the outside surface of the roll. And, the positive static stored in the roll repels the positive ion in the air, which moves through the air and deposits harmlessly on the floor.

The result is that opposite polarity ions from the air accumulate on the outside surfaces of the wound roll, which causes the electric fields measured near the roll to decrease with time. The static charges stored inside the roll will remain inside the roll for week and months when the web is electrically insulating. So, even when we measure decreasing field on the wound roll, the static stored inside the roll will be delivered to our customer.

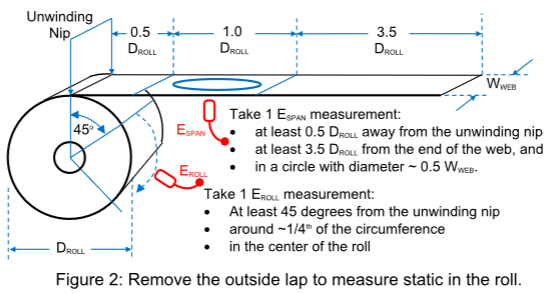

To measure the charge stored in the wound roll in Figure 2, we must first remove the static charges that have accumulated on the outside surfaces of the wound roll. Use a 4-step procedure to measure static on wound rolls.

- Remove outside lap. We must first remove the static charges that have accumulated on the outside surface of the roll. If you take end samples of finished rolls, one common procedure is to cut a slab of material from the roll and remove the first few laps. Measure static just after removing the slab.

To avoid waste, unwind one lap of material shown in Figure 2 that is about 3.5 times longer than the roll diameter DRoll, which is the circumference of the roll.

- Unwind some web. Unwind another length of web about 1.5 times longer than the roll diameter to expose fresh, stored web.

In total, we need to unwind a length of web that is about 5 times larger than the roll diameter, which can be pretty long. For a 3-foot diameter roll, we would need to unwind about 15 feet of web. Have someone hold the unwound web in Figure 2 taught so that it extends from the roll.

- Measure static. Take two static readings. First, measure ESPAN in Figure 2 on the web that was unwound from the roll. Move the static meter over the web in a circle centered on the web with a diameter of about half the web width WWEB. Take the reading far enough from the roll so that you won’t see the static on the roll. When taking this reading, the static meter should always be at least half a roll diameter away from the unwinding nip. Watch the meter display and record the average reading.

Next, measure EROLL in Figure 2 on the wound roll. Move the static meter over the center of the wound roll at least 45 degrees away from the unwinding nip. I find that readings taken too close to the unwinding nip can be highly variable making them unreliable. Move the static meter at least a quarter of the way around the roll. Watch the meter display and record the average reading.

- Plot the measurements in a control chart. Plot the average 0.5*(EROLL + ESPAN) and the range (EROLL ‒ ESPAN) in an X Bar R Control Chart. After auditing static on finished rolls from several runs, we will see normal process variations in the X Bar R Control Chart. And, more importantly, we will see when static is unusually high. We can use the same procedure to audit static on incoming rolls to check for hot rolls from our supplier.

Track the static performance of your operations by auditing static on finished goods. This will verify that problem-free rolls are delivered to your customers. And, this enables you to detect static problems in your operations before static causes customer dissatisfaction. Rachat de voiture hs, camping car accidenté, vendre voiture accidentée www.rachatvotrevoiture.com

About the Author

Kelly Robinson, PE, Ph.D., is the owner of Electrostatic Answer, an engineering consulting company dedicated to eliminating injury and waste from static electricity. You can reach Kelly directly at Kelly.Robinson@ElectrostaticAnswers.com.