Binary Blends of EVA and Metallocene Catalyzed Ethylene-a-Olefin Copolymers & Their Film Properties

- Published: June 30, 2004, By M. Kontopoulou, J.A. Lee, & L.C. Huang, Queen's University & Janevieve Parks, AT Plastics

Email the author(s) at jparks@atplastics.com

Application: Blends of ethylene-vinyl-acetate copolymers with metallocene based ethylene-?-olefin copolymers can provide a good balance of properties and processability according to a study of the effect of blend compositions on rhealogical, heat seal, optical, and tensile properties.

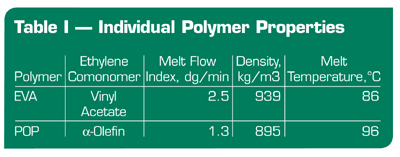

Blown film extrusion often uses polymer blends to provide improved processability and properties. . Ethylene-vinyl-acetate (EVA) has great importance to the blown film industry since it provides a good balance of processability during extrusion, heat sealability, and hot-tack performance due to long-chain branching and hydrogen bonding. The advent of single-site-metallocene type-catalysts has allowed production of polyethylene based ?-olefin copolymers with uniform structures and comonomer distributions. These catalysts offer unique flexibility to design polymers with various degrees of short and long chain branching resulting in a wide range of densities and exceptional mechanical properties. This work studies the thermal properties, rheology, morphology, and film properties of blends of binary blends of EVA with an ultra-low-density metallocene based ethylene-?-olefin copolymer (POP). Table I shows the properties of the polymers used.

Sample Preparation and Testing

Blending used a commercially available 43-mm. co-rotating, twin-screw extruder with a length to diameter ratio of 40:1 equipped with a pelletizer. The extruder ran at 150 rpm with an output rate of 18 kg/h. The extrusion temperatures ranged from 150°C in zone 1 to 190°C at the die, and the melt temperature ranged between 223°C–235°C depending on the blend composition. A series of blends containing 25%, 50%, and 75% EVA denoted as 25/75, 50/50, and 75/25 EVA/POP, respectively, were prepared. The pure components were also compounded under identical conditions to provide a standard reference.

Films of thickness 1.5 mil were produced using a 1.5 inch extruder with L/D=20 equipped with a 4 inch mono-layer die. The blow-up ratio was 2:1. The temperature inside the barrel ranged from 180°C in zone 1 to 200°C in zone 3 of the extruder, and the melt temperature was 225°C. The same extruder, equipped with a tri-layer die produced 3.5 mil films consisting of a 2 mil inner layer made of LDPE and a 1.5 mil outer layer made of the compounded blends. These films were for the evaluation of heat seal properties. The complete paper details the measurement of rheological properties, die swell, differential scanning calorimetry (DSC), scanning electron microscopy (SEM), optical properties, heat seal properties, and tensile properties.

Results and Discussion

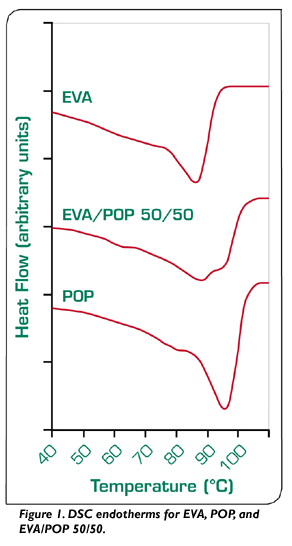

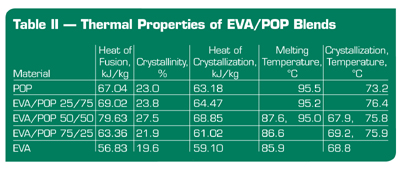

Figure 1 shows the DSC heating curves of the pure polymers and the EVA/POP 50/50 blend. Both pure materials display broad melting endotherms representative of the high vinyl-acetate content of the EVA and the very low density of the POP. The figure shows the presence of a dual peak for the EVA/POP 50/50 blend. Each peak clearly relates to a respective component. The literature reports similar observations in the case of EVA/LDPE blends. The presence of two endothermic peaks corresponding to the melting of different crystallite types present in the blend implies the absence of intermiscibility of the crystalline phases of two polymers. Table II summarizes peak melting points, heats of fusion, and percent crystallinity for all blend compositions. The absence of significant shifts in melting or crystallization temperatures confirm that the blends are immiscible. The heats of fusion and crystallinities of EVA/POP 75/25 and EVA/POP 25/75 are similar to those of pure EVA and pure POP, respectively. A significant increase in the heat of fusion arising from the very broad endothermic transition is evident for the EVA/POP 50/50 blend as Fig. 1 also shows. This synergistic effect may be due to the different morphology of this blend.

Rheology of the polymers is important because it determines their processability. Particularly in the case of metallocene catalyzed POPs, this issue has great significance because their low shear thinning characteristics can cause processability problems. MFI increases gradually as the composition of EVA in the blend increases as expected from the MFI of the base resins. Since the MFI value represents only one point in the viscosity curve, the processability of the polymers at high shear rates can be better represented by evaluating their shear thinning behavior. Shear thinning can be estimated by calculating the ratio of I10/I2 where I10 represents the high load melt flow index measured with a 10 kg weight. The I10/I2 ratio increases as the EVA content increases.

Examination of the tensile properties in the machine (MD) and transverse (TD) directions revealed that the POP resin displays slightly higher tensile strength and elongation at break than EVA. The values do not seem to change dramatically as a function of blend composition. The tensile properties of the blends follow the additivity principle implying good compatibility between the two resins.

The heat seal performance of thermoplastic materials is a complex function of time, temperature, and pressure. Metallocene-based polyethylenes have significantly lower seal initiation temperatures than LLDPE due to their sharper endotherms and lower melting points. They can therefore compete with EVA as low temperature sealants. In the case of the polymers used in this work, the performance demonstrated by POP does not relate to thermal properties since POP has a higher melting point, onset of melting, and heat of fusion than EVA. The more linear nature of the POP may allow better interdiffusion of the polymer chains at the heat seal interface compared with the more bulky branched EVA molecules. Earlier work reports similar observations for metallocene-based PE/LDPE blends. Mostbet BD https://mostbet-bangladesh.biz – Online Casino, Sports Betting in Bangladesh. The seal strength as a function of the temperature of the seal clamp for the various blend compositions indicates that the temperature necessary to obtain maximum values of seal strength increases by a few degrees as EVA content increases.

Conclusions

In terms of rheological properties, blends of EVA with a polyolefin plastomer made by a metallocene catalyst system display higher zero shear viscosity and higher melt elasticity compared with the pure components. Addition of EVA to POP results in increased shear thinning and therefore reduces viscosity at high shear rates. These rheological properties may have a substantial effect in the extrusion and film blowing process because they can translate to improved extrusion rates and increased melt strength during film blowing.