Corona Treating | Why All Films Do Not Treat the Same

- Published: March 30, 2015, By Tom Gilbertson, Enercon Industries Corp.

How well do you understand the relationship between your films and your corona treater?

A treatment level of 2.0 watt density yields very different results on polyethylene terephthalate (PET) compared to polypropylene (PP), and a nominal change in watt density can produce unexpected results. This article looks at the relationship between various films and watt densities. Recognizing that each film has it own signature relationship with a corona treater will help converters control surface energy and improve adhesion.

A treatment level of 2.0 watt density yields very different results on polyethylene terephthalate (PET) compared to polypropylene (PP), and a nominal change in watt density can produce unexpected results. This article looks at the relationship between various films and watt densities. Recognizing that each film has it own signature relationship with a corona treater will help converters control surface energy and improve adhesion.

What is your expectation when you turn on your corona treater? Do you expect to see the same results every time you run film through it? Are you aware of variables that can effect corona treatment results? What do you do when the results you get are different than the ones you expect?

We’ll take a look at aspects of the process that you can control, how to properly set your expectations, and what to do when you get surprising results.

Corona Treating Basics

Its important to recognize what a corona treater does. Although it has the capacity to make films wettable for converting, it is not an all powerful black box that magically transforms all films. It is essentially a capacitor that creates a field of ionized air without regard for the type of film that is passing through it.

Corona does a number of things to a surface. It forms low molecular weight material on the film surface, it oxidizes the film surface, and forms positive and negative sites by adding and deleting electrons. It also rids the film of organic and inorganic contaminants that can interfere with adhesion. We also know from SEM imaging techniques that corona treatment can microscopically change and increase the surface area of films, which increases the chances for successful adhesion.

But since the corona treater doesn’t know what type of film is going through it, it’s your responsibility to understand the dynamics associated with this process.

Variables Under Your Control

Assuming you have your corona treater properly set up with a consistent air gap across the web, the primary variable under your control is the amount of treatment that you apply to your film. This is most effectively measured as watt density.

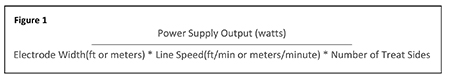

It's not as simple as setting the kilowatt indicator on your power supply. The watt density formula takes into consideration the corona treater's kilowatt output, the width of the treatment area, the number of sides being treated, and the speed of the film being treated (see Figure 1).

As a point of reference, most corona treating systems for converting applications are sized between a watt density of 2 and 3 watts per square foot per minute.

Of course, you can’t simply look at a film and determine if it has been surface treated, let alone to what level. The best indicator of surface treatment success is running your full process and evaluating your adhesion results. A quick test to check for changes in the surface after treatment is a dyne test.

Dynes are a unit of measurement that indicates the surface energy of a film. It’s important to note three important considerations when using dyne levels. The first is that the dyne results depend on properly conducting the test and interpreting the results; variations of ±2 dynes are very common.

Secondly, your dyne measurements prior to and after treating are only testing a small part of the film. Lastly, please understand that reaching a target dyne level does not guarantee adhesion. It is not uncommon to see different adhesion results from film with identical dyne levels.

There is a great deal of information available in the industry on how to properly conduct dyne tests. Dyne testing ranges from simple dyne pen markers to more accurate Meyer Rod testing procedures. Whichever method(s) your team chooses to adopt, be sure to properly train your personnel in following proper test protocols.

Factors Affecting a Film’s Responsiveness to Corona Treatment

In general, plastic films are chemically inert, have limited bonding sites, and are hydrophobic (Figure 2). We’ll save surface contamination and migrating additives for later in the discussion.

Figure 2

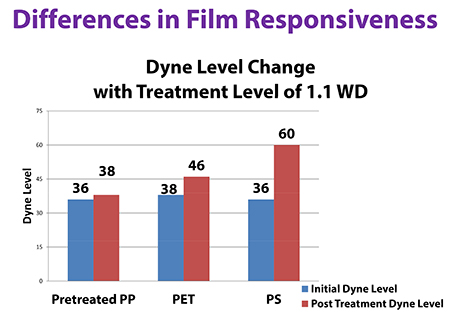

Many corona treater users expect that applying the same amount of treatment to different films will produce the same dyne result. This is simply not true. The first variable is the film’s initial dyne level. The second variable is the film’s receptiveness to being affected by corona treatment.

In Figure 3, we share laboratory trial data comparing the surface treatment results of pretreated PP, PET, and polystyrene (PS). All films were treated with a watt density of 1.1. You can see that the PS was very receptive to corona treatment, and its dyne level increased from 36 to 60 dynes. The PET was somewhat responsive, and an increase to 46 dynes as reached. The PP film however barely showed any increase.

If a target of 44 dynes was needed, a higher watt density would need to be applied. If you recall the watt density formula from above, you will see that you can either increase the power output, reduce the speed, or do both to increase the watt density.

Figure 3

Since the corona treater is incapable of knowing what type of film is running through it, it is imperative that your operators understand that each film will respond differently to applied treatment levels and set the watt density accordingly. One caution, increases in watt density do not create proportional changes in dyne levels, therefore it’s important to test and develop recipes for the treatment levels that work best for each of your applications.

How films respond to changes in Treatment Levels

Generally speaking, higher watt densities produce higher dyne levels. However you cannot use watt density to predict dyne levels. Why is that? A corona treating system is not an intelligent device. For example, it has no idea that the film running today is new or old, has more or less additives than the film ran previously.

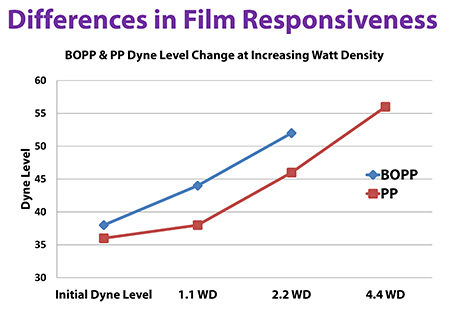

Below is a graph of how different films responded to increases in watt density. What can we learn from this data?

- In our lab trial (Figure 4) biaxially oriented polypropylene (BOPP) and PP responded differently to the same amount of watt density. A watt density of 1.1 produced a dyne level change of 6 dynes on the BOPP, but only 2 dynes on the PP. Another clear example of films responding differently to the same level of surface treatment.

- To achieve a dyne level of 52 the BOPP material required an applied treatment level of 2.2 watt density. By comparison, doubling that watt density level to 4.4 on PP generates a dyne level of 56. A great example that reminds that each film has a unique “signature” or responsiveness to treatment.

Figure 4

It should be noted that in some cases film of the same type can yield different results. This is why documenting your own results is critical. For example, let’s say that your operation routinely achieves similar results to those shared in Figure 5. One day your operations team discovers that the film is not achieving the expected dyne levels at the same watt density.

Certainly the cause could be related to the corona treater, and if it is, it is usually a very straightforward process to identify the problem. However in these cases, more often than not, it is usually discovered that the unexpected surface treatment result is caused by a change in the film. Age of the film, storage conditions of the film, and changes to slip agents and additives can affect how your film responds to treatment.

The cost of higher dyne levels

Our discussion of different films’ responsiveness to corona treatment could end here, but we want to leave you with a final takeaway regarding the cost of your next corona treater.

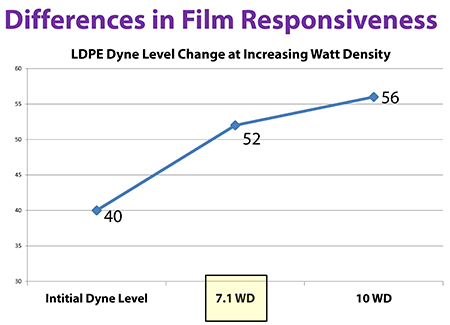

The graph below (Figure 5) illustrates the responsiveness of low-density polyethylene (LDPE) to various watt densities. Note the move from 40 to 52 dynes required a watt density of 7.1! Recall that we stated as a general guideline a watt density between 2 and 3 is normally sufficient for most converting applications.

Figure 5

So what are the ramifications of requiring a 7.1 watt density? The physical size and cost of the corona treater increases tremendously. A larger ground roll is required to dissipate the heat created by this higher power level, additional electrode assemblies may be required to achieve the watt density, the air flow requirement for the exhaust system will increase, and of course the power supply will need to have increased capacity as well.

All of these changes significantly increase the cost of the corona treater.

But wait just a minute; do we really need a watt density of 7.1? Well, that depends on how you determine your window for success. Are 52 dynes being recommended by your ink or coating supplier or from your customer? Have you tested your actual adhesion results at different dyne levels? This is a great reminder that the entire reason you are corona treating is to improve adhesion, not to achieve a dyne level.

Summary

Corona treaters apply treatment measured in watt density to improve surface wettability. Generally speaking higher watt densities produce higher dyne levels, but the relationship is not always linear. Lab trials shared in this article illustrate how various films have a unique “signature” response to various watt densities.

The first step in understanding the relationship between film and corona treatment is to recognize that the corona treater is incapable of knowing how film will respond to its treatment, and that each film has a unique “signature” response to treatment. Ultimately, it is up to your operation to establish and document how incremental levels of treatment affect the ultimate success of your adhesion goals.

ABOUT THE AUTHOR

Tom Gilbertson is VP application engineering for surface treating at Enercon Industries Corp., Menomonee Falls, WI. He can be reached at 262-255-6070.