tna Presents Innovations at interpack 2023 to Help Food Producers Achieve Sustainability Goals

- Published: April 13, 2023

Visit Hall 14, booth C56 and D56, for a sneak peek at the factory of the future

At interpack 2023, tna solutions will showcase its processing and packaging solutions for food manufacturers worldwide. Visitors may enter a virtual factory that enables remote planning, scoping and testing of production lines, reducing carbon footprint and downtime. Also, for the first time in Europe, tna will exhibit the latest iteration of its flagship vertical form fill and seal (VFFS) packaging system, the tna robag® 3e, complemented by the tna auto-splice 3. Combined, this ‘Perfect Pair’ can increase production uptime by up to 5 percent with only a 200mm increase in overall floor space.

tna’s proprietary sustainability calculator will be available for visitors to assess how the use of single-serration jaws on VFFS packaging systems can help reduce film consumption and enhance sustainability credentials.

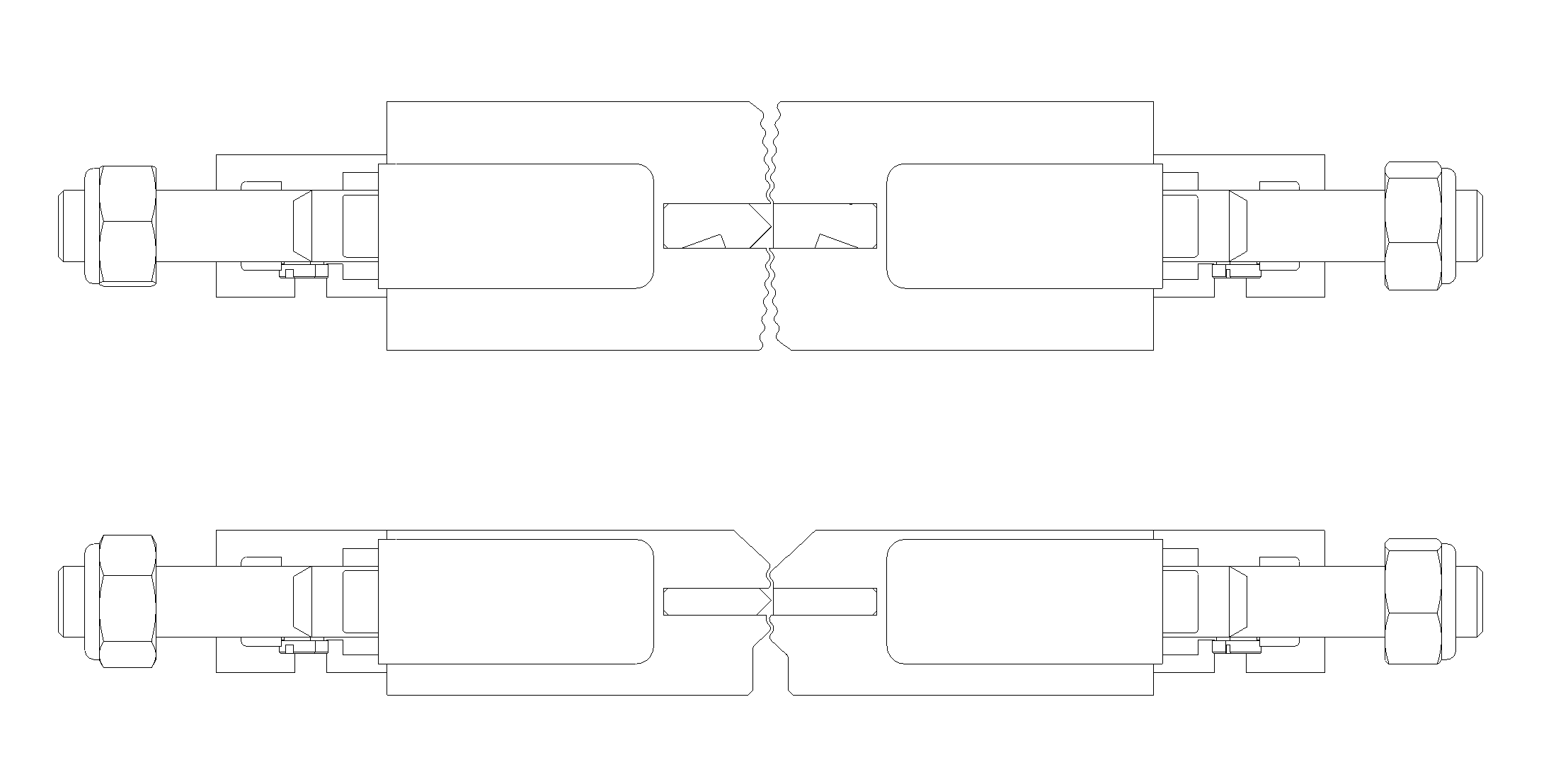

The tna sustainability corner will showcase capabilities of the tna robag to run a range of industry compliant sustainable film materials. It also demonstrates an integrated line for snack producers featuring the aforementioned tna robag® 3e, and the tna auto-splice 3 with EtherCAT® real-time protocol and an integrated display controller system. The latest software relays information from the tna checkweigher or from the product in-seal inspection to inform operators on the optimal weighing bucket configuration for prompt troubleshooting, significantly reducing rejects, product and material waste. As a result, snack manufacturers can produce up to 2,800 more bags per line per day with minimal downtime and only 200 millimeters added to the VFFS system footprint.

tna experts will guide visitors through possible changes that can drive meaningful improvements in reducing environmental impact, such as the tna robag® 3e, which lowers product waste levels to 0.1 percent, and offers a more efficient, sustainable packaging operation. With the world’s smallest VFFS footprint, the system delivers energy savings up to 20 percent thanks to its enhanced productivity and intuitive power saving software, which automatically shuts the system down when not in use.

Reducing Material Waste

tna will showcase single-serration jaws that help to reduce the consumption of biaxially oriented polypropylene (BOPP), a recyclable but non-biodegradable material. The sustainability calculator, available throughout the show, allows snack producers to evaluate potential film savings. For example, single-serration jaws enable a 5-millimetre material saving per seal. On VFFS systems that produce 150 bags per minute, these savings translate into 2.26 million bags per month. In a factory of 10 packaging lines, operating at least 12 hours a day, it results in almost 390 kilometres of film saved a month.

tna experts will be on hand throughout the show to offer advice and discuss individual sustainability needs and requirements. Visit www.tnasolutions.com to learn more.