Static Eliminators: Solutions for Winders, Unwinders and Slitters

- Published: August 05, 2024

Choosing Eliminators for Best Performance and Price

By Dr. Kelly Robinson, Founder, Electrostatic Answers

For winders, unwinders and slitters, static control is focused on the wound rolls because static charges on wound rolls can severely shock operators, ignite fires in solvent handling operations, and cause stick and jamming of cut sheets in customer applications. Even small amounts of static charges on webs entering winding rolls can cause problems because rolls store all the charges on the long length of web being wound.

Choosing the right static eliminator for winding rolls, unwinding rolls and slitters is all about controlling static on rolls. First, let's look at winders.

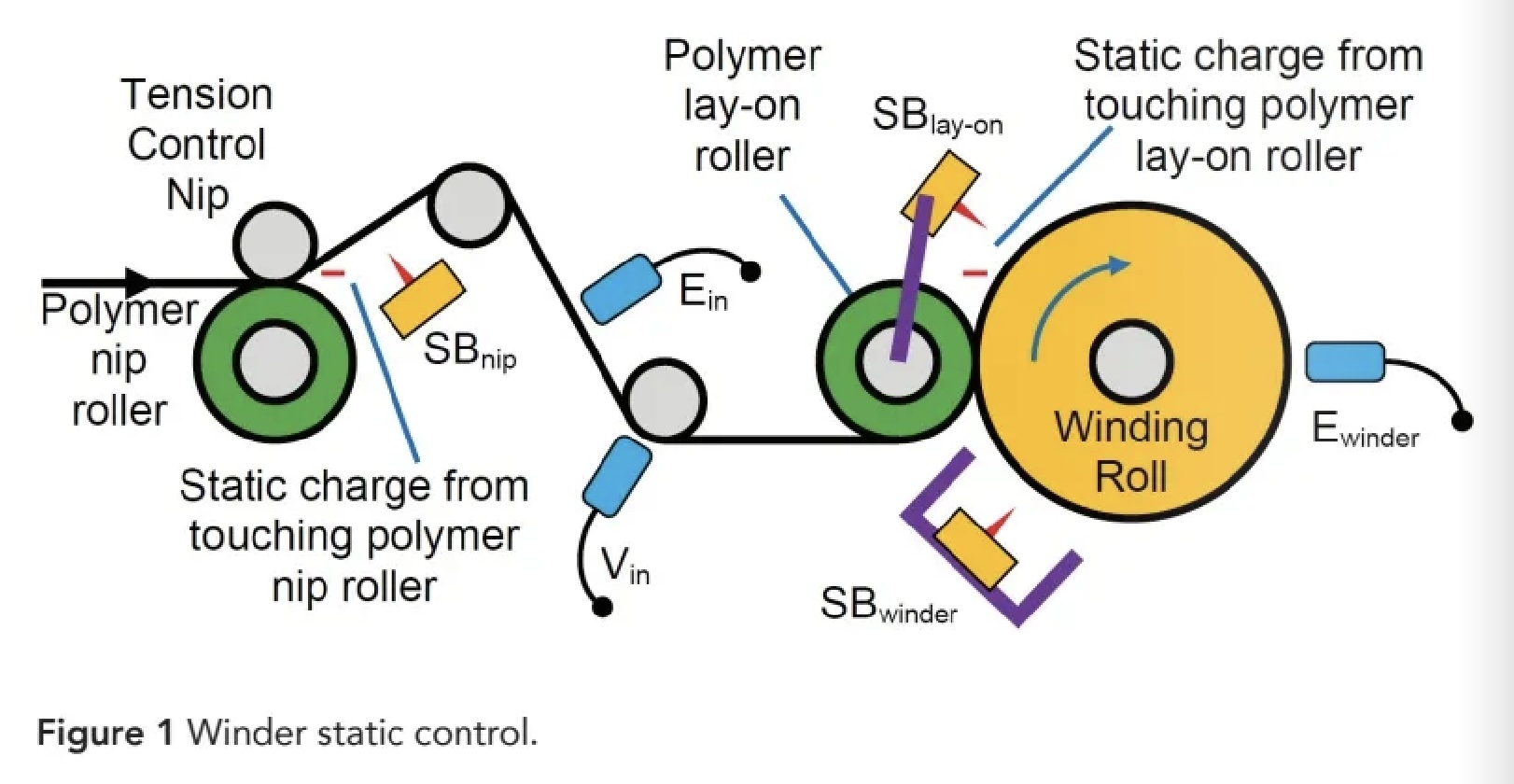

Controlling static on winders is challenging because we need to neutralize static charges from at least two different sources: 1. static charges on the web entering the winding roll and 2. Static charges deposited on the winding roll from a lay-on roller.

Static Charges on the Entering Web

The web entering the winding roll in Figure 1 should be as charge-free as possible by practicing good static control upstream of the winder. For this winder, a nip controls the winding tension. Powered static bar Snip neutralizes the static charges deposited on the web from the nip. This neutralizer should face the web surface that touched the polymer nip roller.

A powered static bar will fully neutralize the static charge, so use powered static neutralizers near the winding roll. Use a high-performance, short-range static bar because the distance to the web from the static bar remains constant on this web span.

Verify that the web entering the winding roll is nearly charge-free by making two static measurements: 1. Electric field Ein, and 2. Voltage Vin.

Measure electric field Ein in Figure 1 with a handheld electrostatic fieldmeter. Many are commercially available that are about the size of a card deck. The electric field Ein should not exceed 2 KV/ cm (5 KV/in). If electric field Ein is too big, clean or replace SBnip.

Measure voltage Vin in Figure 1 using an electrostatic volt-meter. There are few commercially available electrostatic voltmeters.

I recommend using an Advanced Energy Trek 520-21 or equivalent. The voltage of the web when it is wrapped on a grounded, metal idler roller should not exceed 0.5 V/mm of web thickness. For example, when running a 2 mil (50 mm) thick web, voltage Vin on the web entering the winding roll should not exceed 25 V. If voltage Vin is too big, take additional voltage measurements upstream of the winder to find the source of the high voltage.

Static Charges from the Lay-on Roller

Lay-on rollers are often used on winding rolls to prevent telescoping by squeezing out air between the wound laps. An unwanted by-product from the lay-on roller in Figure 2 is charge on the outside surface of the winding roll.

Use powered static neutralizer SBlay-on in Figure 2 to neutralize static charges on the winding roll. If you can mount this static bar to the frame of the lay-on roller, use a short-range static bar because the distance to the winding roll remains constant. The lay-on roller vibrates, which shortens the service life of the static bar. Use a mechanically strong static bar to extend the service life.

An alternative is to use powered static neutralizer SB-winder in Figure 1 to neutralize static charges on the winding roll. Mount this static bar on a machine frame outside of the maximum diameter of the winding roll. Roll handling is easier with Swinder below the winding roll. Protect Swinder from damage by mounting it inside an electrically insulating, fiber-glass U-channel.

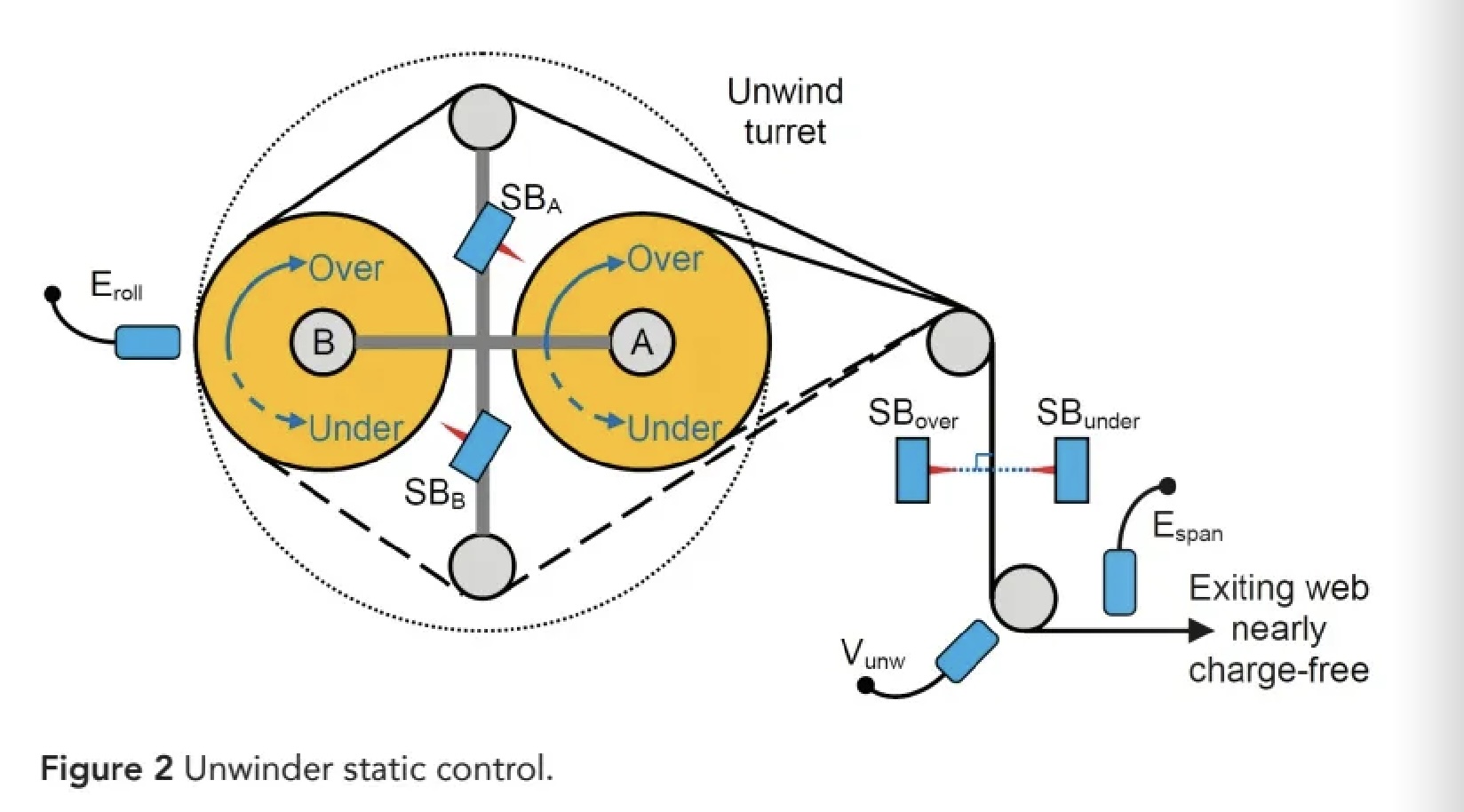

Controlling static charges on unwinding rolls protects the operation from static charges stored on the roll from previous processes. Static control for unwinding rolls is challenging because we need to neutralize charges on both surfaces of the web exiting the unwinding roll. The best practice is to use two powered static bars (see: K.S. Robinson, "Static Control for Roll-to-Roll Manufacturing, "IEEE Transactions on Industry Applications, vol. 59, no. 1, pp. 93-103, Jan.-Feb. 2023).2

Install a powered static neutralizer for each spindle on the unwind turret in Figure 2.

SBA is for spindle A and SBe is for spindle B. Static bars powered with 24 VDC are available so that additional sliprings for electrical power on the turret are not need-ed. Use long-range static bars for SBa and SB because distances to the unwinding rolls grows as the rolls expire.

After the web exits the unwinding turret, install two powered static bars SBover and SBunder in Figure 2 to neutralize static charges on the web exiting the unwinding roll. These two static bars should be installed symmetrically, which means two things. First, a line drawn from one static bar to the other must intersect the web at a right angle. Second, the distance from each static bar to the web must be the same. Use high-performance, short-range static bars because the distance to the web remains constant.

Once installed, energize only one of these two bars. When over-unwinding, energize only SBover. SBunder should be turned-off. Similarly, when under-unwinding, energize only Sunder SBover should be turned-off.

Verify that the web in Figure 2 is nearly charge-free by making three static measurements: 1. Electric field Eroll, 2. Electric field Espan, and 3. Voltage Vunw.

Electric field Eroll in Figure 2 should not exceed 6 KV/cm (15 KV/in). If electric field Eroll is too big, clean or replace both static bars SBA and SBB.

Electric field Espan in Figure 2 should not exceed 2 KV/cm (5 KV/in). If electric field Espan is too big, clean or replace static bar SBover or SBunder, whichever is energized.

The voltage Vunw in Figure 2 should not exceed 0.5 V/mm of web thickness. If voltage Vunw is too big, verify the function of SBA, SBB, and either SBover or SBunder whichever is energized.

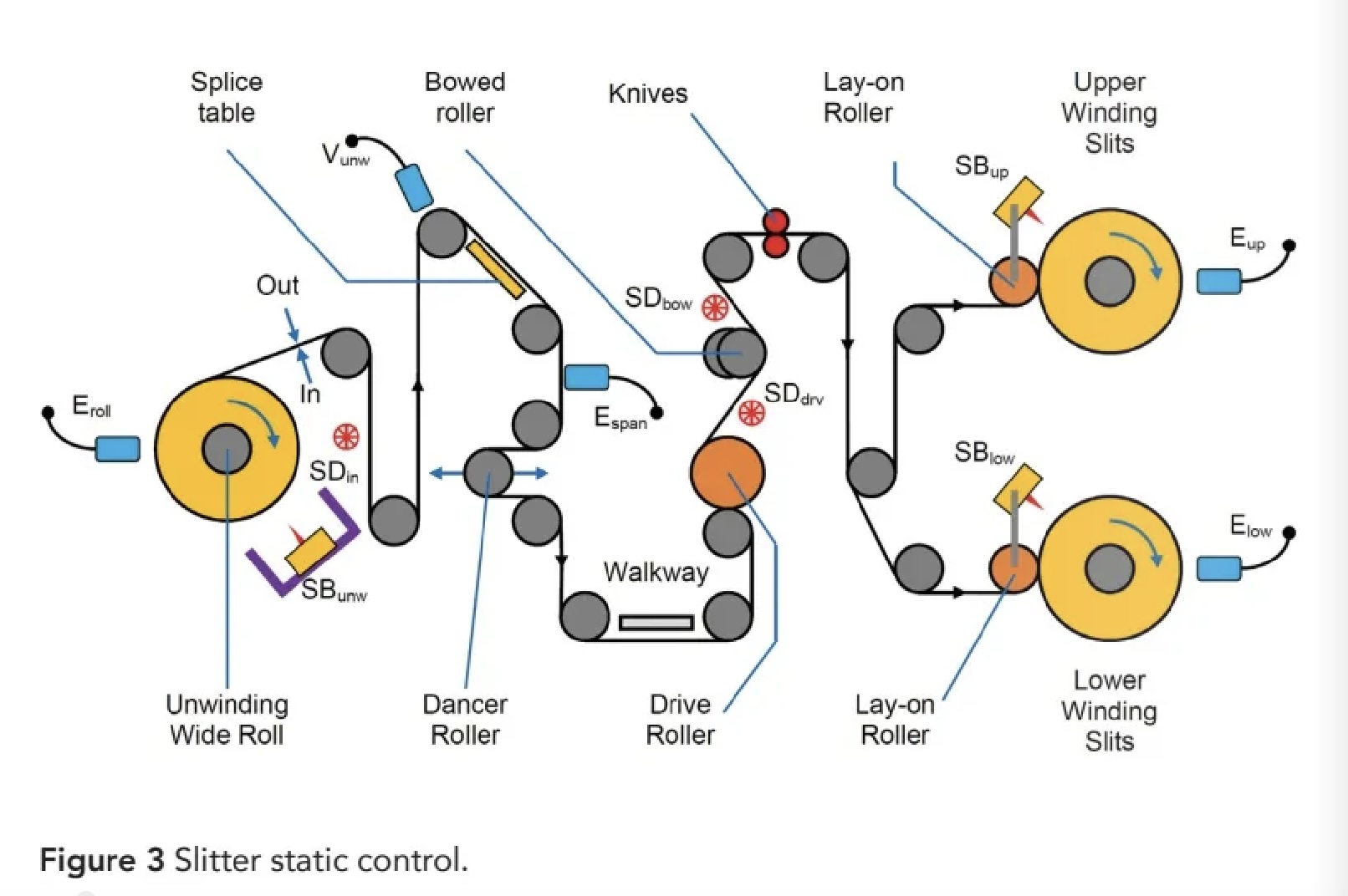

Static control for the slitter in Figure 3 uses powered static bars on the lay-on rollers from Figure 1 and two static neutralizers for the unwinding roll from Figure 2. When unwinding in only one orientation, passive static dissipater SDin may be used instead of a powered dissipater to save money. The passive static dissipater may be a static brush, a tinsel strand, an ionizing cord, an ionizing rod or another equivalent device. Bristles that break from a static brush or tinsel may contaminate your product. lonizing cords or rods minimize contamination.

Slitters are compact and congested. It is difficult to find places to take verification measurements. Usually, I take measurements near the splice table.

Verify the operation of the unwind dissipaters in Figure 3 by making three static measurements: 1. Electric field Eroll, 2. Electric field Espan and 3. Voltage Vunw.

Electric field Eroll in Figure 3 should not exceed 6 KV/cm (15 KV/in). If electric field Eroll is too big, clean or replace SBunw, which may be protected by mounting it inside an electrically insulating, fiberglass U-Channel.

Electric field Espan should not exceed 4 KV/cm (10 KV/in). If electric field Espan is too big, clean or replace static bar SBunw and passive static dissipater SDin.

Voltage Vunw in Figure 3 should not exceed 0.5 V/mm of web thickness. If voltage Vunw is too big, verify the function of SBunw and SDin. Electric field Espan should not exceed 4 KV/cm (10 KV/in). If electric field Espan is too big, clean or replace static bar SBunw and passive static dissipater SDin.

Voltage Vunw in Figure 3 should not exceed +0.5 V/mm of web thickness. If voltage Vunw is too big, verify the function of SBunw and SDin.

Verify that the winding slits in Figure 3 store little charge making two static measurements: 1. Electric field Eup and 2. Electric field Elow.

Electric field Eup in Figure 3 should not exceed 2 KV/cm (5 KV/in). If Eup is too big, clean or replace SBup.

Electric field Elow in Figure 3 should not exceed 2 KV/cm (5 KV/in). If Elow is too big, clean or replace SBlow.

Finally, control the static charges on the web entering the slitter knives to minimize contamination from slitter debris. The slitter in Figure 3 has two sources of static charge just upstream of the knives: 1. The drive roller and 2. A bowed roller.

Dissipate static charges from touching the drive roller in Figure 3 using passive static dissipater SDdrv on the web exiting the drive roller facing the web surface that touched the polymer drive roller.

Dissipate static charges from touching the bowed roller in Figure 3 using passive static dissipater SDbow on the web exiting the bowed roller facing the web surface that touched the roller.

Focus on winding and unwinding rolls to find the best static eliminators for winders, unwinders and slitters. Use high performance, short-range static bars when the distance to the web remains constant. Use long-range static bars on winding and unwinding rolls when the distance from the static bars to the roll surfaces varies. Save money by use passive static dissipaters far upstream of the winding rolls. Near the winding rolls, use powered static dissipaters.

2 https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=9915453

About the Author

Dr. Kelly Robinson writes on static issues occurring in converting processes. Robinson founded Electrostatic Answers, has 40-plus years experience in industrial problem solving and was named Top Manufacturing Consulting Services Provider 2023 by Managing MFG. He can be reached at Kelly.Robin-son@ElectrostaticAnswers.com.